Improvement method for air use of vertical disk filter

A vertical disc filter and filter technology, applied in the filter field, can solve the problems of affecting normal production, low wind pressure, insufficient wind for vertical disc, etc., to achieve the effect of ensuring normal use of wind and solving process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

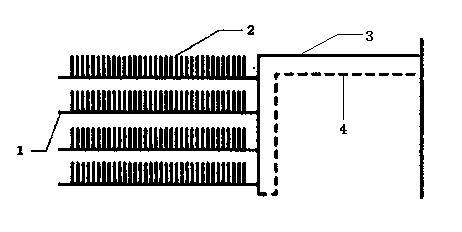

[0011] Taking the process of producing alumina by the Bayer method in the No. 1 alumina branch of China Aluminum Corporation Shanxi Branch as an example, it uses a total of 8 vertical disc filters, each with 4 5.08cm pipes to ensure air supply, totaling 32 5.08cm pipes (2), these 32 5.08cm pipes (2) are divided by 4 20.32cm pipes (1), the total required air volume is about 240m 3 / min. Now enter the vertical pan main air supply pipe (3) with a pipe diameter of 20.32cm. When the production is high, the air supply is insufficient. You can connect another 20.32cm pipe (4) to the vertical pan filter on the main line, which can fully meet the requirements of 8 The air volume required for the vertical discs to be opened together, the air flow diagram of the vertical disc filter is shown in the figure figure 1 As shown, the dotted line is the newly added pipeline (4).

[0012] The low-pressure machine will inevitably stop suddenly during operation, and it will take 5 minutes to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com