Electrothermal film and preparation method thereof

A technology of electric heating film and parts by weight, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low thermal efficiency, affecting service life, electromagnetic radiation hazards, etc., and achieve improved conductivity, thermal stability, and thermal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

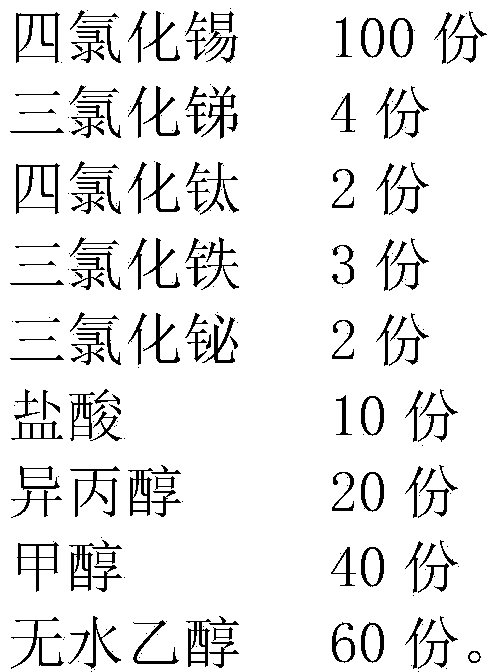

[0031] An electrothermal film is prepared from components comprising the following parts by weight:

[0032]

[0033] The preparation method of the above-mentioned electrothermal film comprises the following steps:

[0034] (1) Weigh the above-mentioned components according to weight and volume;

[0035] (2) 10gSnCl 4 ·5H 2 O was added to 48ml of absolute ethanol, stirred to make it evenly mixed;

[0036] (3) Add 0.4gSbCl 3 , 0.2gTiCl 4 , 0.3gFeCl 3 and 0.2gBiCl 3 Add to a mixed solution of 16ml of isopropanol, 32ml of methanol and 10ml of 10M hydrochloric acid, stir to mix evenly;

[0037] (4) Mix the mixed solution obtained in step (2) and step (3), and stir evenly to obtain the electric heating film stock solution.

[0038] (5) Clean the surface of the substrate purple sand with alcohol and heat it to 500°C.

[0039] (6) Heat the electrothermal film stock solution obtained in step (4) to 50°C, spray the heated electrothermal film stock solution onto the surface ...

Embodiment 2

[0043] An electrothermal film is prepared from components comprising the following parts by weight:

[0044]

[0045] The preparation method of the above-mentioned electrothermal film comprises the following steps:

[0046] (1) Weigh the above-mentioned components according to weight and volume;

[0047] (2) 9gSnCl 4 ·5H 2 O was added to 64ml of absolute ethanol, stirred to make it evenly mixed;

[0048] (3) Add 0.5gSbCl 3 , 0.4gTiCl 4 , 0.5gFeCl 3 , 0.3g BiCl 3 and 0.1gBr 2 Add to a mixed solution of 24ml of isopropanol, 32ml of methanol and 10ml of 10M hydrochloric acid, stir to mix evenly;

[0049] (4) Mix the mixed solution obtained in step (2) and step (3), and stir evenly to obtain the electric heating film stock solution.

[0050] (5) Clean the surface of the substrate quartz glass with alcohol and heat it to 600°C.

[0051] (6) Heat the electrothermal film stock solution obtained in step (4) to 50°C, spray the heated electrothermal film stock solution on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com