Automatic stator production line

An automatic production line and automatic technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of poor uniformity of product parts, rising production costs of micro-motors, and increased labor demand gap, so as to save labor and use resources and enhance competition. force, promote the effect of process improvement and innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

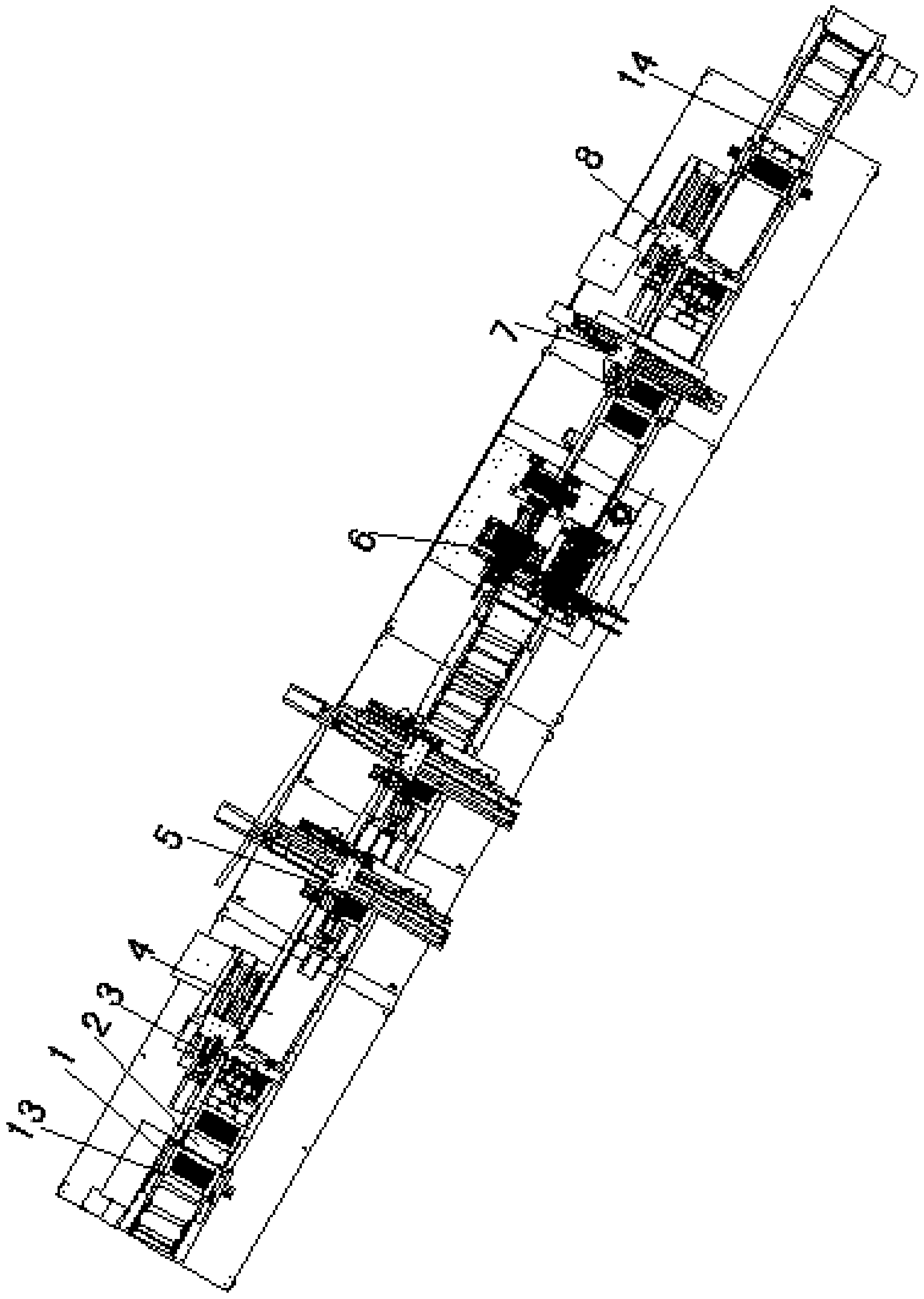

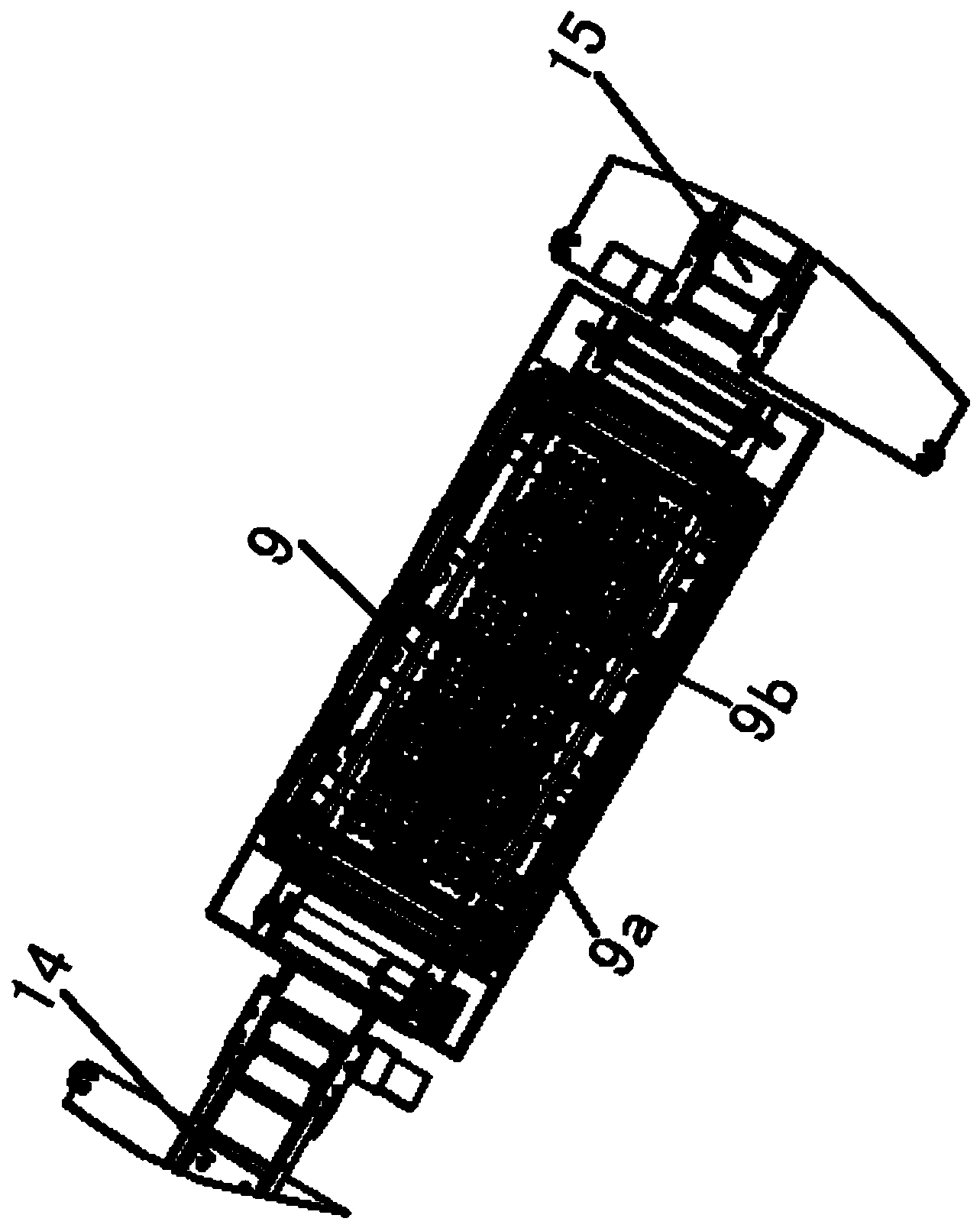

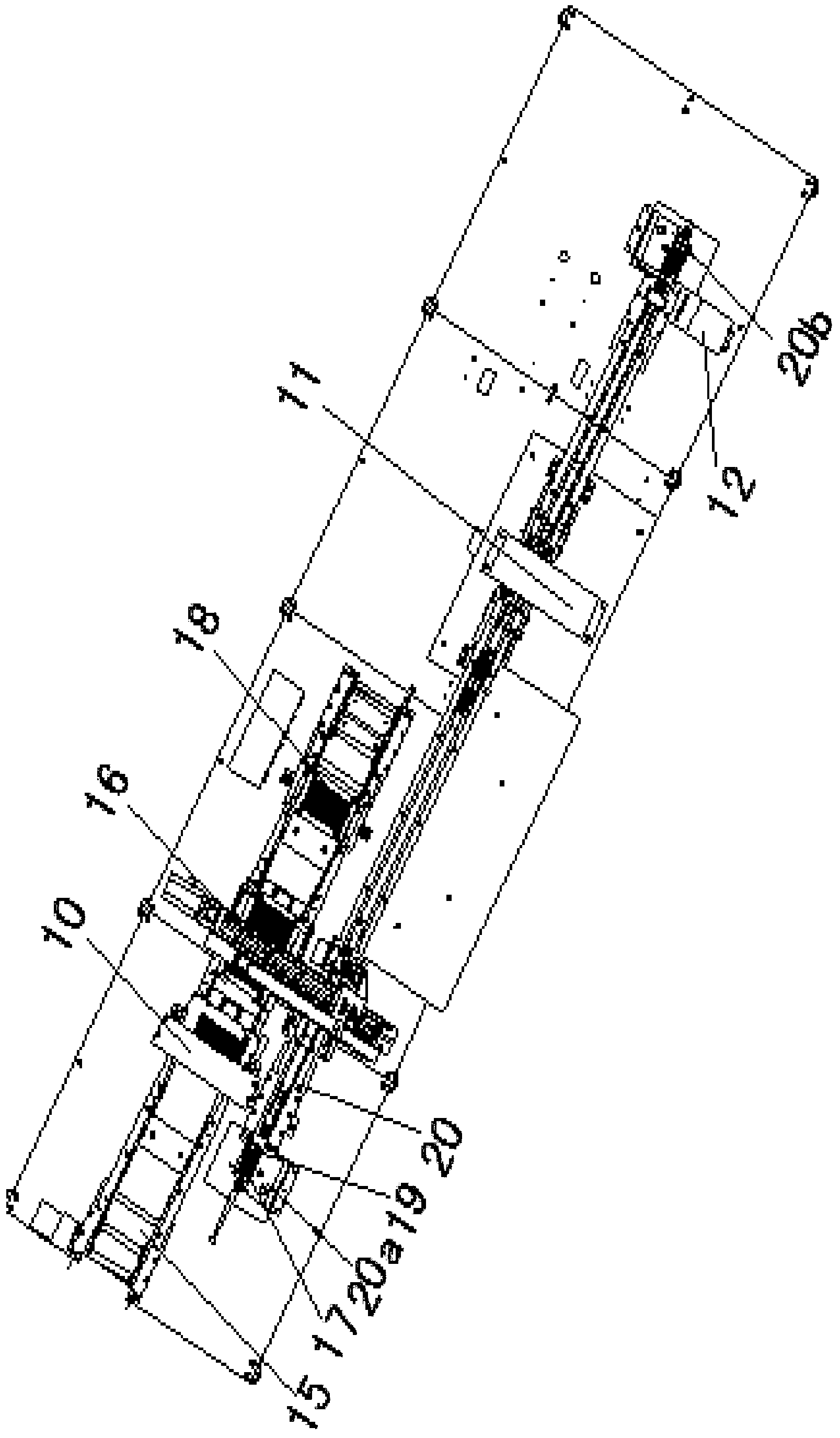

[0042] Such as figure 1 Shown is the top view of the first part of the stator automatic production line embodiment of the present invention; as figure 2 Shown is the second part top view of the stator automatic production line embodiment of the present invention; image 3 Shown is the top view of the third part of the embodiment of the stator automatic production line of the present invention; an automatic stator production line of the present invention includes a PLC control system and a fixture turnover device, and the fixture turnover device includes a turnover disc and is used to drive the turnover disc to move The transmission device also includes a stator casing automatic arrangement unit 3, an automatic point catalyst unit 4, a stator casing direction screening unit 5, an automatic magnet loading unit 6, and an automatic magnet pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com