Two-way air suction type electric cable cooling device

A cooling device and air extraction technology, which is applied in the direction of cooling busbar devices, substation/switchgear cooling/ventilation, etc., can solve the problems of unfavorable cooling, suction effect needs to be improved, etc., and achieve reliable working results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

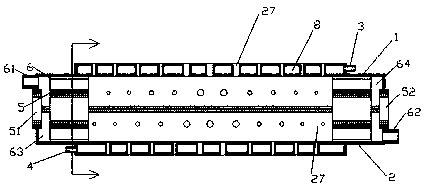

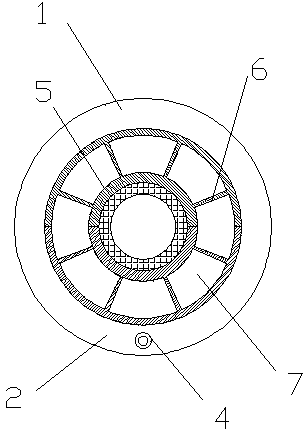

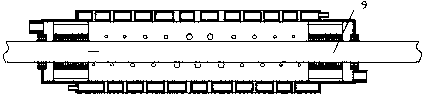

[0013] A two-way pumping type cable cooling device, comprising an upper semicircular part 1 and a lower semicircular part 2, the upper semicircular part 1 and the lower semicircular part 2 are fastened to form a cylinder, and the upper semicircular part 1 and the lower semicircular part 2 are arranged at the interface There is a sealing strip; a cylindrical coolant barrier layer is provided on the outer peripheral surface of the cylinder, and the inside of the cylinder has a cavity for accommodating the cable 9, and the cylindrical coolant barrier layer surrounds The cavity, and the liquid inlet 3 is fluidly connected to the upper right end of the cylindrical cooling liquid barrier layer, and the liquid outlet 4 is fluidly connected to the lower left end; the cylindrical cooling liquid barrier layer is also provided with Circular air hole 27, the inner circumferential sidewall of the circular air hole 27 can seal and isolate the circular air hole 27 from the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com