Blue-phase liquid crystal display with low driving voltage and high transmittance

A low driving voltage, blue-phase liquid crystal technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as high driving voltage, affecting display transmittance, reducing driving voltage, etc., to achieve voltage reduction Small, high transmittance, the effect of reducing the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

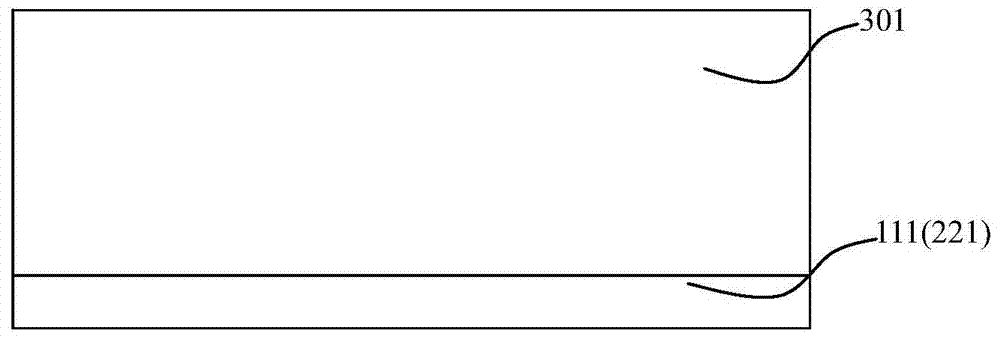

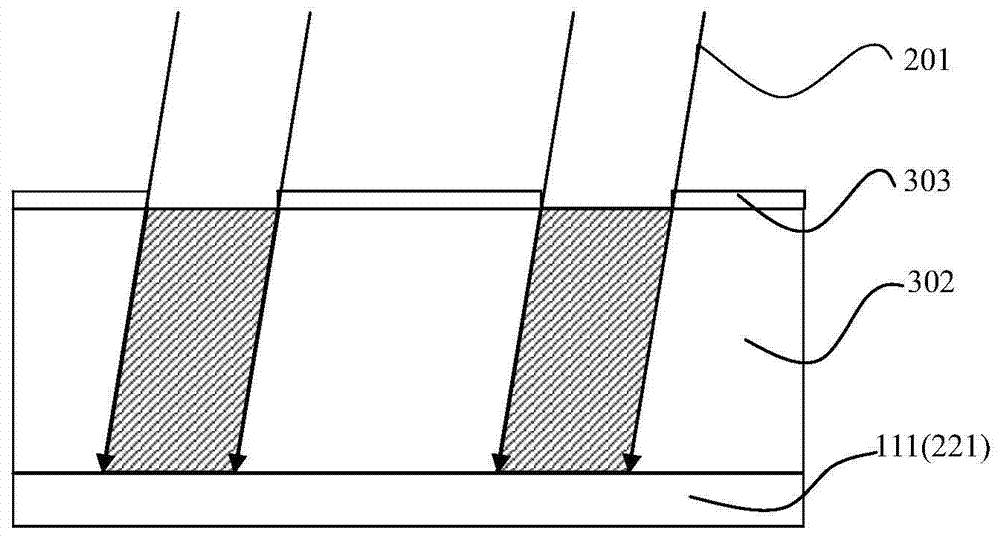

[0061] figure 1 It is a longitudinal sectional view of a specific embodiment of the polymer stabilized blue phase liquid crystal mentioned in this patent, such as figure 1 As shown, in this embodiment, it includes the first substrate layer 11, the middle parts 13, 13(1) and 14 and the second substrate layer 12; wherein, the composition of the first substrate layer is the first polarized light from bottom to top sheet 113, the first glass substrate 112 and the first insulating layer 111; the composition of the second substrate layer from bottom to top is the second insulating layer 121, the second glass substrate 122 and the second polarizer 123; the middle part includes: the first Three transparent layers 13 and 13(1), and a blue-phase liquid crystal layer 14, wherein the third transparent layer includes split-shaped protrusions 131 and 131(1), electrode layers 132 and 132(1), and third insulating layers 133 and 133 (1). In the figure, we can clearly see that the first subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com