ld laser phase mixing device and method

A laser and mixed-phase technology, which is applied in the device, optics, optical components, etc. to control the output parameters of the laser, can solve the problems such as the inability to eliminate the influence of phase inhomogeneity in ranging accuracy, poor phase uniformity, etc., and achieves simple structure and low cost. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

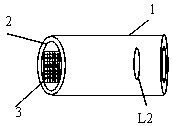

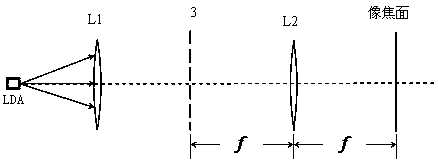

[0019] Such as figure 1 As shown, the LD laser phase mixing device according to an embodiment of the present invention includes a micromotor 2, an orthogonal grating 3, a collimating lens L2, and a fixed cylindrical seat 1 for installing the micromotor 2 and the collimating lens L2. Wherein, the micro motor 2 can be installed on one end of the fixed cylinder base 1 , and the orthogonal grating 3 is installed on the micro motor 2 . The micro motor 2 is preferably a hollow-shaft motor, and the orthogonal grating 3 can be fixed on the end face of the hollow-shaft motor. After passing through the orthogonal grating 3, the LD laser can be shot onto the collimator lens L2 through the axis of the motor. The orthogonal grating 3 can rotate at high speed driven by the micro motor 2, and the orthogonal grating 3 is located on the object focal plane of the collimator lens L2, so that the light waves emitted by each point on the light emitting surface of the LD light source pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com