Yarn dip-dyeing device

A yarn and dyeing agent technology, applied in the field of dyeing and finishing equipment, can solve the problems of yarn entanglement, knotting and less yarn, and achieve the effect of preventing mutual entanglement and knotting and expanding the dyeing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the figure, a yarn dipping device includes a dye vat 1, and a vertical side seat 3 with a rotating core 2 is arranged on one side of the dye vat 1, the rotating core 2 is circular, Several winding rods 4 are arranged on the rotating core 2 , and each winding rod 4 has the same length from the center of the rotating core 2 .

[0014] The rotating core 2 is provided with three identical winding rods 4 , and the three winding rods 4 are equidistantly distributed on the rotating core 2 .

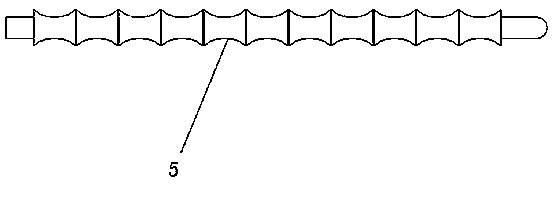

[0015] Each of the winding rods 4 is provided with an isolation slot 5 for separating the yarns.

[0016] The yarn is wound on three identical winding rods 4, and the yarn is continuously dyed through the rotation of the rotating core 2. In addition to using three identical winding rods 4, four identical winding rods 4 can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com