Preparation method of aminated sponge/graphene three-dimensional composite structural material

A three-dimensional composite and structural material technology, applied in the direction of fibrous fillers, dyed low-molecular organic compounds, etc., can solve the problems of difficult mass production, limited performance, high cost, etc., to achieve broad application, good amination effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

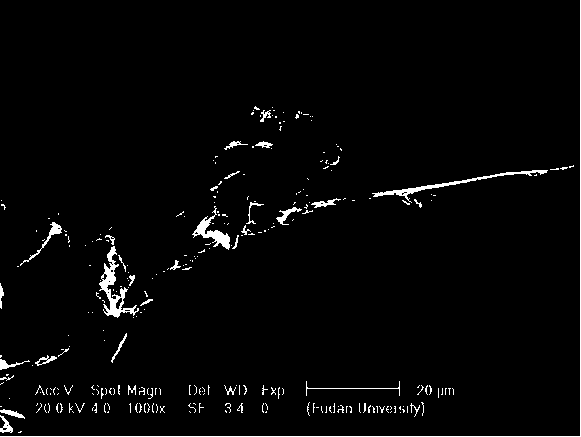

[0027] Sonicate 15ml graphite oxide solution of 0.5mg / ml in an ultrasonic cleaning instrument for 1 hour to obtain a graphene oxide solution; then add 320ul of ethylenediamine and 80ul of ammonia water, and stir; put in (12mm*12mm*12mm) The sponge was left to stand in a water bath at 95°C for about 6 hours; after taking it out, it was freeze-dried for 24 hours. The graphene sponge is wrapped with loose graphene hydrogel, and the graphene content in the sponge is less, and the graphene in the sponge does not form a sheet structure, but is an irregular block. The SEM morphology of the sample prepared in this embodiment can be found in figure 2 shown.

Embodiment 2

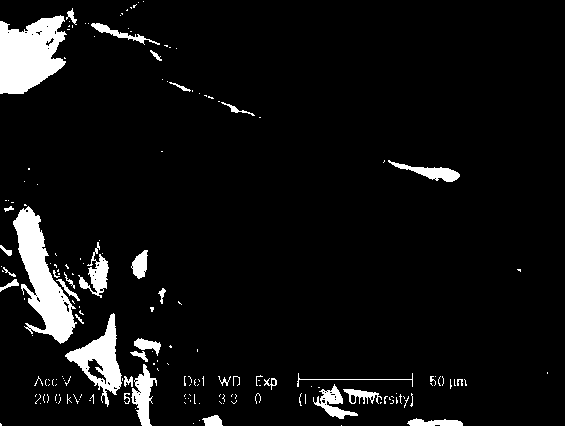

[0029] Sonicate 2mg / ml 15ml graphite oxide solution in an ultrasonic cleaning instrument for 1 hour to obtain a graphene oxide solution; then add 320ul of ethylenediamine and 80ul of ammonia water, and stir; put in (12mm*12mm*12mm) The sponge is left to stand in a water bath at 95°C for about 6 hours, and the sponge graphene is wrapped with loose graphene hydrogel; after taking it out, it is freeze-dried for 24 hours. For the samples prepared in this example and the samples prepared by the traditional immersion method, the corresponding optical morphology can be found in figure 1 shown. The obtained three-dimensional graphene is in a regular sheet shape, and the graphene content in the sponge is relatively large, accounting for 25% of the sponge mass, and the amino group content is relatively high, reaching about 10%. image 3 The SEM morphology of the samples prepared for this example.

Embodiment 3

[0031] Sonicate 2mg / ml 15ml graphite oxide solution in an ultrasonic cleaning instrument for 1 hour to obtain a graphene oxide solution; then add 320ul of ethylenediamine and 80ul of ammonia water, and stir; put in (12mm*12mm*12mm) The sponge is left to stand in a water bath at 95°C for about 16 hours, and the sponge graphene is wrapped with a strong graphene hydrogel; after taking it out, it is freeze-dried for 24 hours. The obtained three-dimensional graphene is a regular flake, and the graphene content in the sponge is relatively large, accounting for 33% of the sponge mass. Depend on Figure 4 It can be seen that the surface of the sample prepared in this example has been modified with functional groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com