A kind of environment-friendly solvent-free foam base material for shoe leather and preparation method thereof

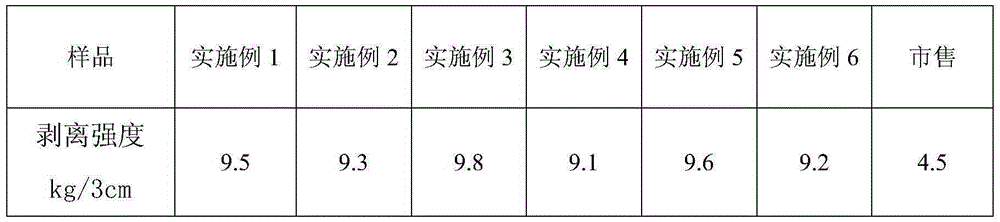

An environment-friendly, solvent-free technology, which is applied in the preparation of the environment-friendly solvent-free foam base material for shoe leather, and the field of environment-friendly solvent-free foam base material for shoe leather, which can solve the gap between shoe leather and low peel strength, etc. problem, to achieve the effect of controllable reaction speed, high peel strength and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The synthesis of environment-friendly solvent-free foaming bottom material for shoe leather comprises the following steps:

[0033] 1. Synthesis of Component A

[0034] The raw materials include the following components by weight: 100 parts of polyether polyols with a molecular weight of 2000, 2 parts of 1,4-butanediol, 0.2 parts of water, and 0.2 parts of dimethoxysiloxane; the polyether polyols are .

[0035] Process: Add polyether polyol, 1,4-butanediol, water, and dimethoxysiloxane to the reactor in sequence, control the temperature of the reactor at 55°C, measure the moisture after stirring for 1.5 hours, and adjust the moisture to pass Afterwards, component A is obtained.

[0036] 2. Synthesis of component B

[0037] The raw materials include the following components by weight: 76.8 parts of polyether polyol with a molecular weight of 2000, and 25.6 parts of isocyanate.

[0038] Process: add isocyanate and polyether polyol to the reaction kettle in sequence, m...

Embodiment 2

[0043] It is basically the same as Example 1, except that the poly(ethylene adipate) butanediol ester diol with the same molecular weight is used in the raw material instead of polyether polyol.

Embodiment 3

[0045] The synthesis of environment-friendly solvent-free foaming bottom material for shoe leather comprises the following steps:

[0046] 1. Synthesis of Component A

[0047] The raw materials include the following components in parts by weight: 100 parts of polyether polyol with a molecular weight of 1000, 3 parts of 1,2-propylene glycol, 0.1 part of water, and 0.5 part of dimethoxysiloxane.

[0048] Process: Add polyether polyol, 1,2-propylene glycol, water, and dimethoxysiloxane to the reactor in sequence, control the temperature of the reactor at 50°C, measure the moisture after stirring for 2 hours, and adjust the moisture to pass the preparation A component.

[0049] 2. Synthesis of component B

[0050] The raw materials include the following components by weight: 103.6 parts of polyether polyol with a molecular weight of 1000, and 51.8 parts of isocyanate.

[0051] Process: add isocyanate and polyether polyol to the reaction kettle in turn, measure the percentage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com