Composite flocculating agent

A composite flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unretrieved technologies, and achieve the effect of high effective content, simple operation steps, and high cationicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

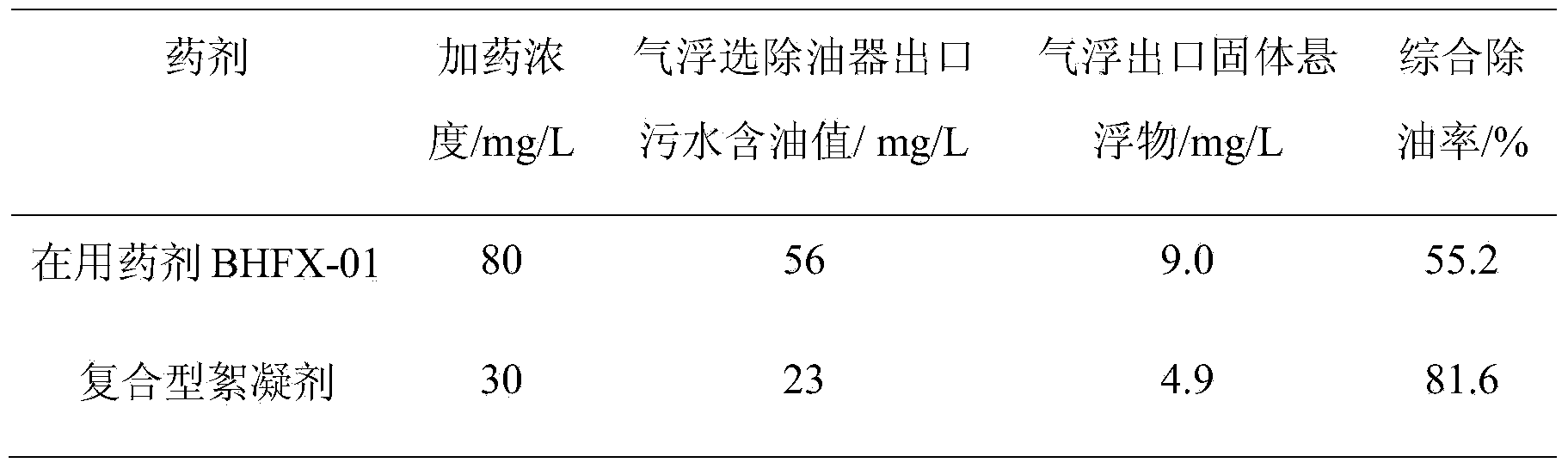

Examples

Embodiment 1

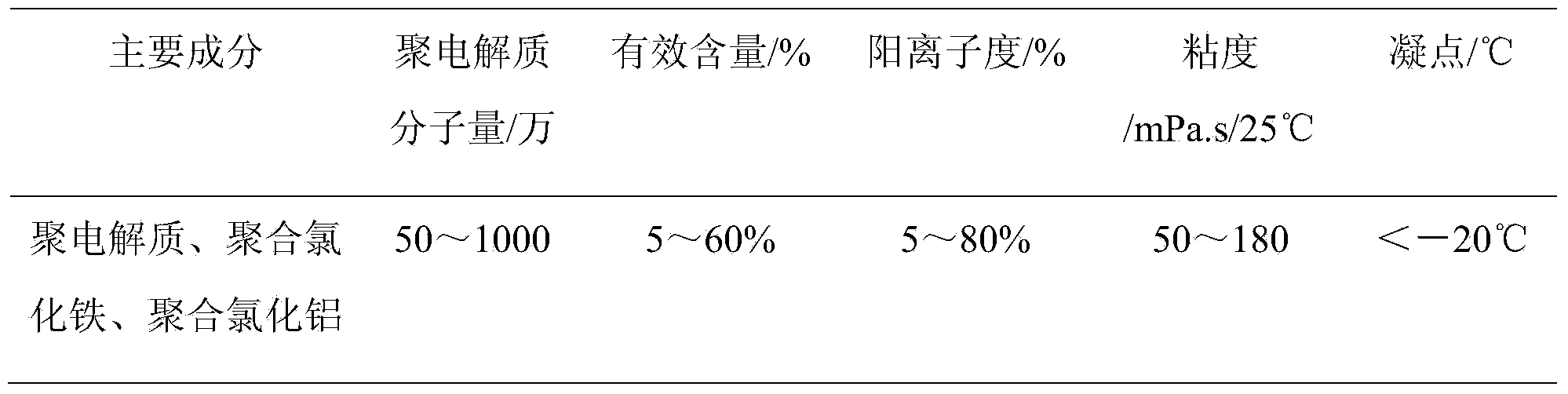

[0022] Example 1: Prepare polyelectrolyte first, and then prepare composite flocculant. There are six methods for preparing composite flocculants.

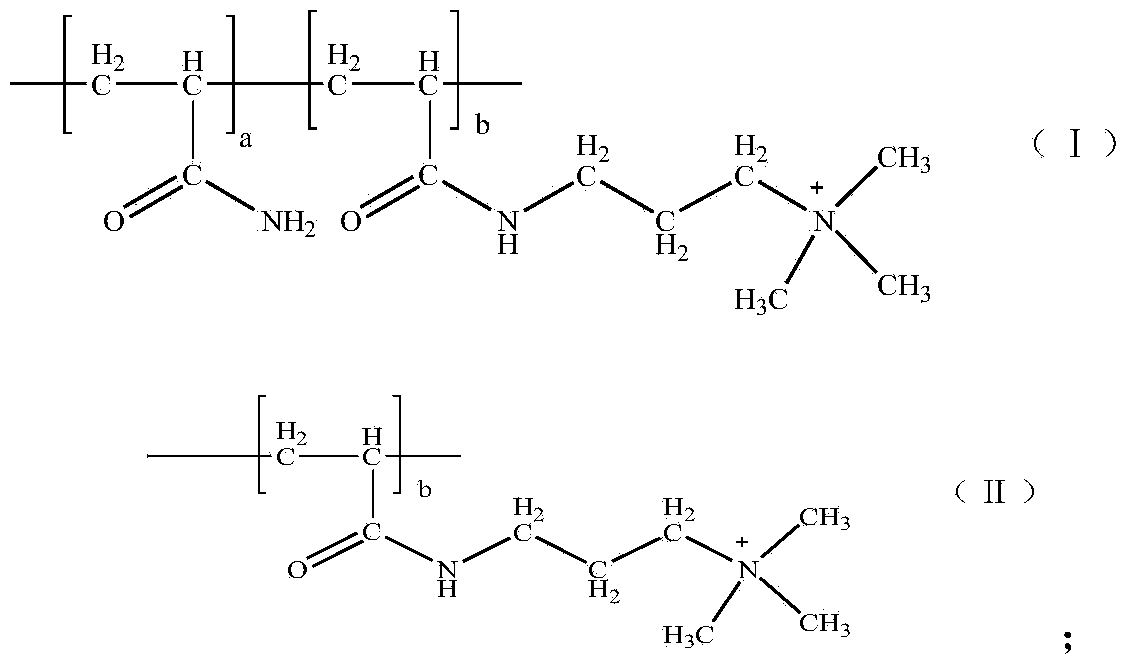

[0023] Method 1: Prepare a composite flocculant with a binary copolymer of acrylamide and acrylamidopropyltrimethylammonium chloride as a polyelectrolyte and liquid polyferric chloride with a concentration of 5-20% as a Lewis acid

[0024] Disodium edetate and deionized water are 5.0×10 in mass ratio -4 :78, stir and dissolve evenly, add acrylamide, acrylamide propyl trimethylammonium chloride, the molar ratio of the two monomers is 1:3, heat up to 30°C, stir and dissolve and protect with nitrogen for 0.5 hours; add 2, 2'-Azobis(2-methylpropionamidine) dihydrochloride initiates the polymerization reaction at 45°C for 12 hours, 2,2'-Azobis(2-methylpropionamidine) dihydrochloride accounts for 2 The ratio of the total mass of the monomer is 0.045%, the temperature is raised to 90°C and the reaction is kept for 4 hours, the temperat...

Embodiment 2

[0052] Example 2: A one-step method directly prepares a composite flocculant, that is, synchronously reacts monomers for preparing polyelectrolytes and Lewis acid to prepare a composite flocculant. There are six methods for preparing composite flocculants.

[0053] Method 7: One-step direct preparation of composite flocculant from acrylamide, acrylamidopropyltrimethylammonium chloride, and liquid polyaluminum chloride with a concentration of 5-20%

[0054] Add disodium ethylenediaminetetraacetic acid, deionized water, 5-20% liquid polyaluminum chloride, acrylamide, and acrylamidopropyltrimethylammonium chloride into the reaction kettle at the same time, in which ethylenediaminetetraacetic acid The mass ratio of disodium and deionized water is 5.0×10 - 4 :78, the molar ratio of acrylamide and acrylamidopropyltrimethylammonium chloride two monomers is 1:3, and the mass-to-total mass ratio of liquid polyaluminum chloride with a concentration of 5-20% is 8:9 , raised the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com