Preparation method and application of bismuth titanate-titanium oxide heterojunction nano-material

A nano-material, titanium oxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the complex ballast water treatment, which cannot meet the requirements of safety, practicality, economy, effectiveness and environmental tolerance and other problems, to achieve the effect of short sterilization time, simple preparation method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

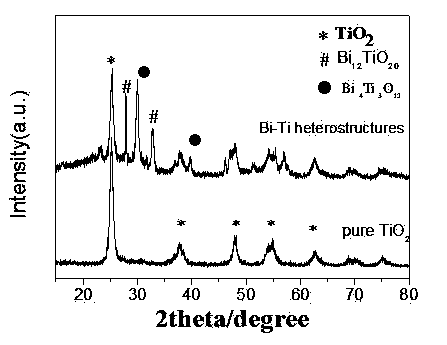

[0031] Mix glycerol and ethanol, stir until evenly mixed, add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixed solution, stir vigorously for 20min, transfer the whole mixed solution to the reaction In the kettle; the molar ratio of the bismuth element contained in bismuth nitrate to the titanium element contained in tetrabutyl titanate is 0.1:1; the volume ratio of tetrabutyl titanate, glycerol and ethanol is 1: 4.7: 11.7 . Place the reaction kettle in a constant temperature oven at 120°C to react for 24 hours; after cooling, filter and dry the mixture in the kettle and place it in a temperature-programmed furnace for calcination at 500°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles. The obtained sample can be determined to be Bi by X-ray diffraction pattern 12 TiO 20 with Bi4 Ti 3 o 12 and TiO 2 mixtures such as figure 1 As shown, that is, bismuth titanate-titanium oxide (Bi 1...

Embodiment 2

[0035] Mix glycerol and ethanol, stir until evenly mixed, add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixed solution, stir vigorously for 20min, transfer the whole mixed solution to the reaction In the kettle; the molar ratio of the bismuth element contained in bismuth nitrate to the titanium element contained in tetrabutyl titanate is 0.2:1, and the volume ratio of tetrabutyl titanate, glycerol and ethanol is 1: 4.7: 11.7 . Place the reaction kettle in a constant temperature oven at 120°C for 24 hours; after cooling, filter and dry the mixture in the reaction kettle and place it in a temperature-programmed furnace for calcination at 500°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles , the obtained sample can be determined to be Bi by X-ray diffraction pattern 12 TiO 32 with TiO 2 mixtures such as Figure 4 As shown, that is, bismuth titanate-titanium oxide (Bi 12 TiO 32 / TiO...

Embodiment 3

[0039] Mix glycerol and ethanol, stir until evenly mixed, add bismuth nitrate solid and dissolve it completely, slowly add tetrabutyl titanate into the mixed solution, stir vigorously for 20min, transfer the whole mixed solution to the reaction In the kettle; the molar ratio of bismuth element contained in bismuth nitrate to titanium element contained in tetrabutyl titanate is 0.3:1, and the volume ratio of tetrabutyl titanate, glycerol and ethanol is 1:4.7: 11.7. Place the reaction kettle in a constant temperature oven at 120°C to react for 24 hours; after cooling, filter and dry the mixture in the kettle and place it in a temperature-programmed furnace for calcination at 500°C for 3 hours. After cooling, grind the calcined product into a powder with uniform particles. Such as Figure 6 As shown, the obtained sample can be determined to be Bi by X-ray diffraction pattern 12 TiO 32 、 Bi 2 o 3 and TiO 2 A mixture of bismuth titanate-titanium oxide (Bi 12 TiO 32 -Bi 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com