Fixed variable hydraulic system of mining dump truck

A technology for mining dump trucks and hydraulic systems, which is applied to vehicles with inclined bearing motion, fluid steering mechanisms, etc., can solve the problems of erratic steering, the stability of the steering system is not guaranteed, and the steering pump is not used. Displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

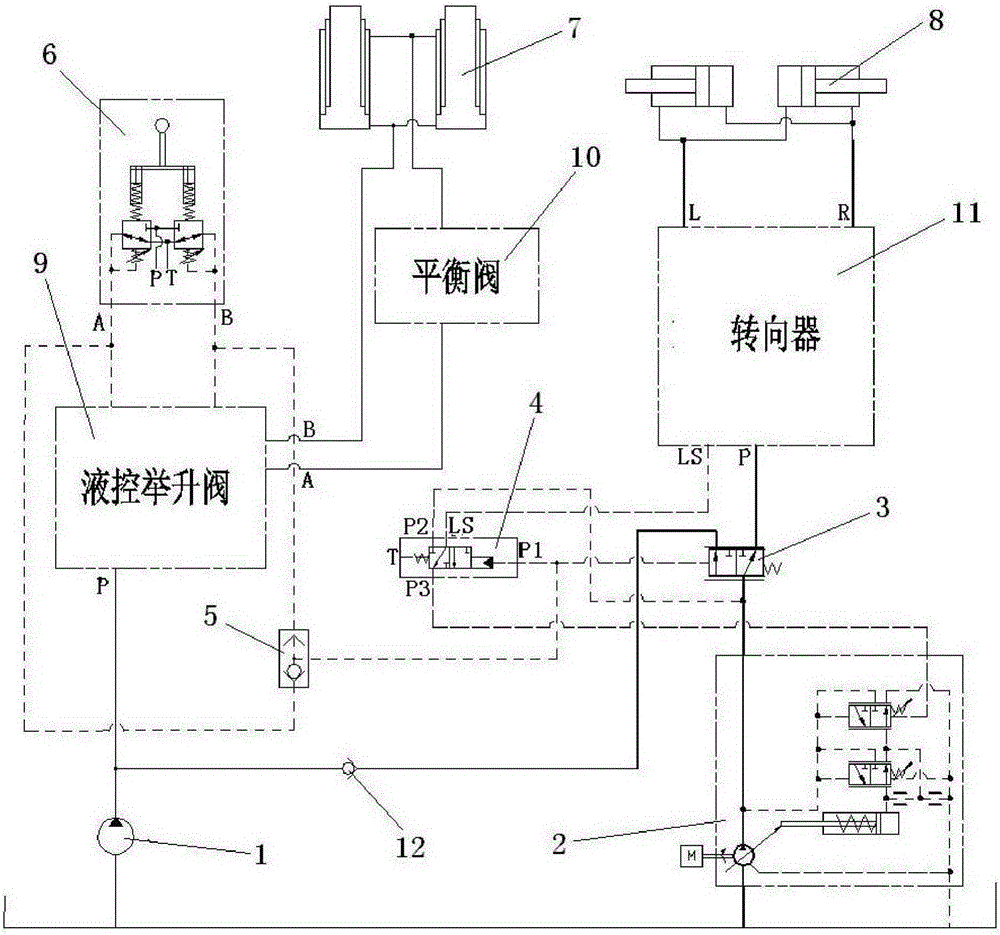

[0026] The specific implementation will be described below in conjunction with the accompanying drawings.

[0027] like image 3 As shown, in this embodiment, the fixed displacement hydraulic system of the mining dump truck includes a hydraulic lift system and a hydraulic steering system; wherein the hydraulic lift system includes a lift cylinder 7, a hydraulically controlled lift valve 9, a pilot valve 6, The balance valve 10, lift pump 1, and pump ports of lift pump 1 are connected to the P port of the hydraulic control lift valve, and the A and B ports of the pilot valve 6 are connected to the control oil port of the hydraulic control lift valve 9. Port A and port B of the lift valve 9 are connected to the lift cylinder 7, and the balance valve 10 is connected between the hydraulically controlled lift valve 9 and the lift cylinder 7, that is, connected to the small cavity oil port of the lift cylinder and the hydraulic control valve. Between the A ports of the lift valve; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com