Manufacturing technology of color ball with shrunk printed film and color ball

A production process and printing film technology, applied in decorative arts, special decorative structures, etc., can solve the problems of many human factors, high labor costs, defective products, etc., and achieve the effect of simple and fast process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

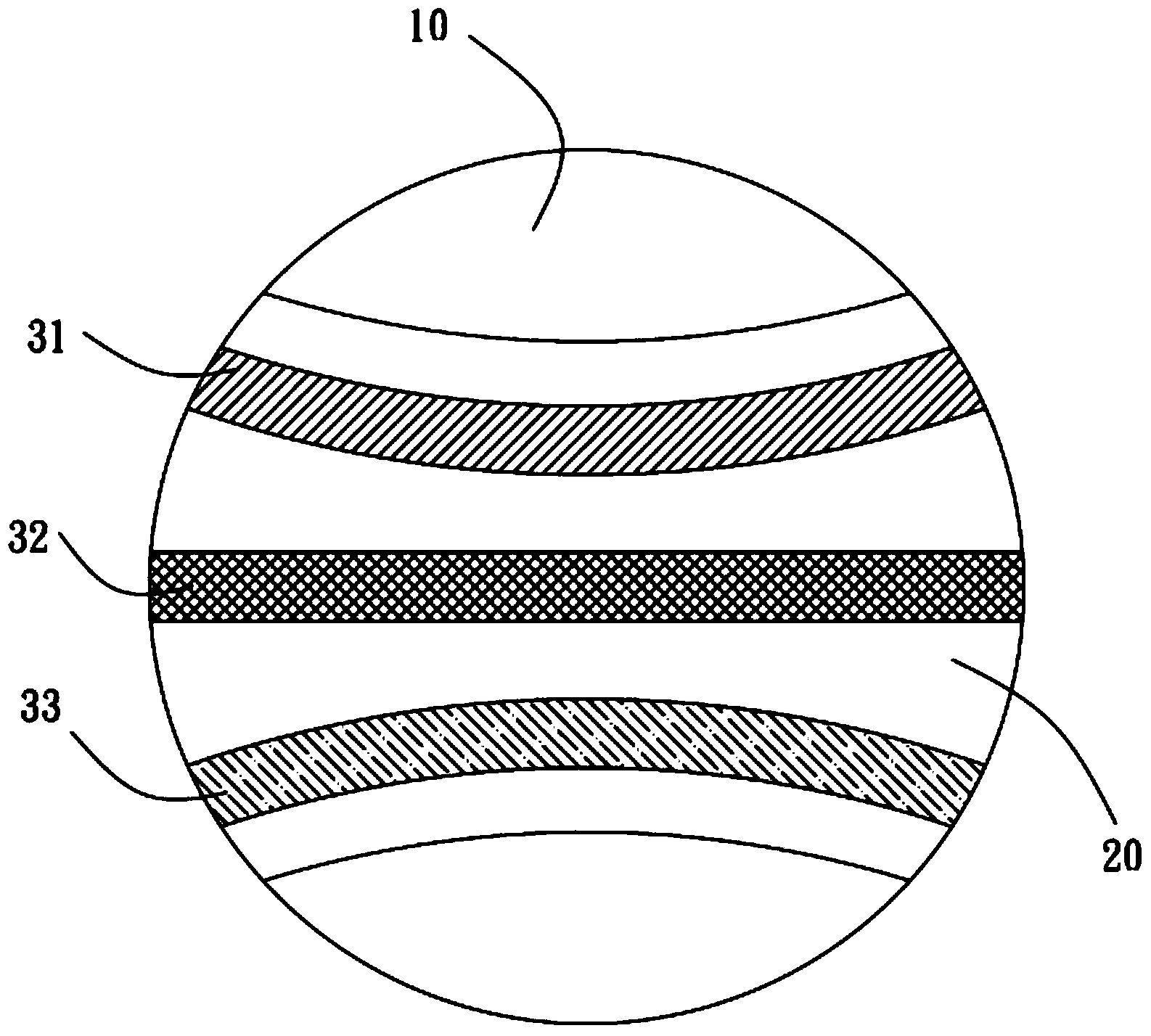

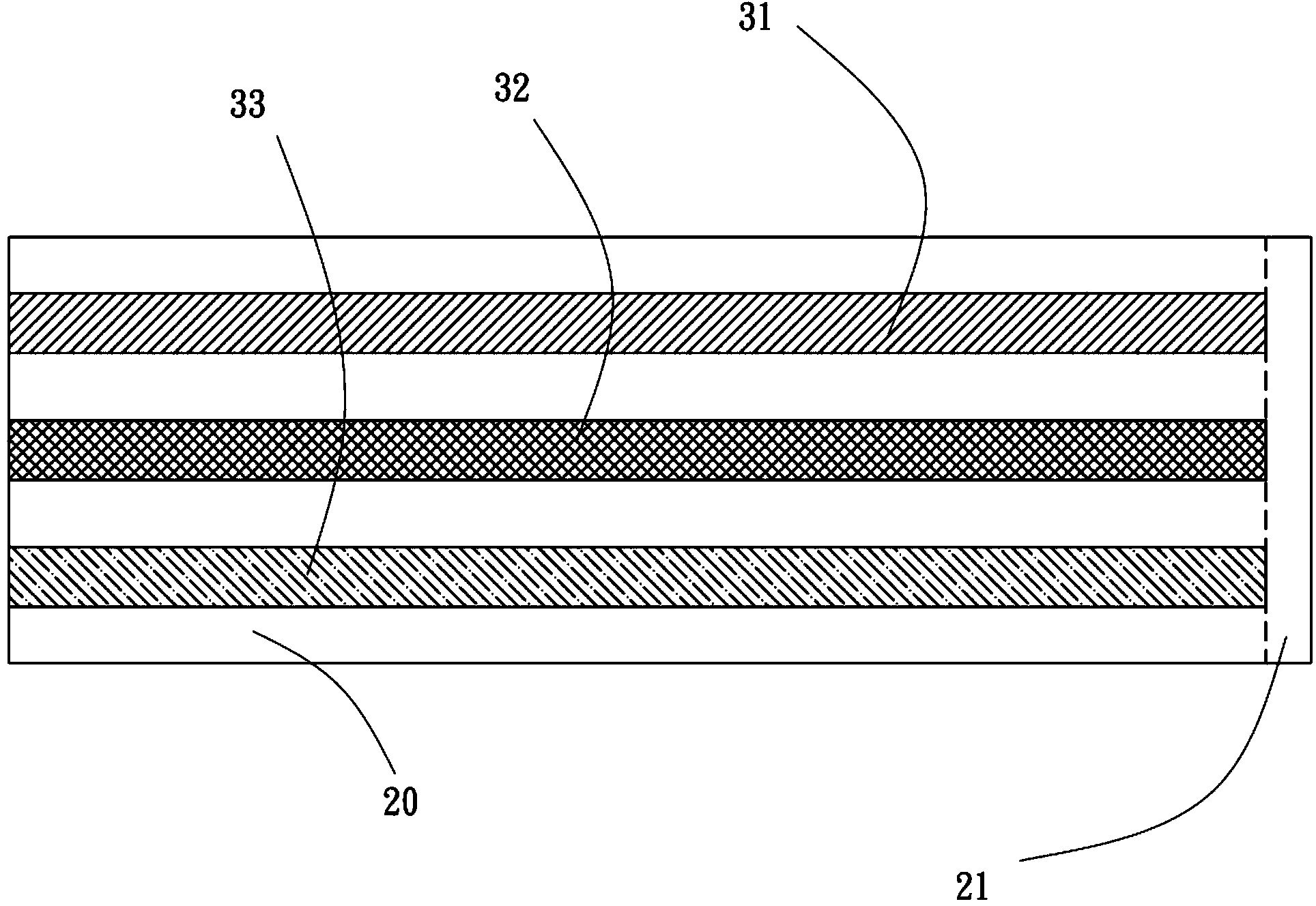

[0026] Please refer to Figure 1 to Figure 3 , be the manufacturing process of the colored ball that has the shrink printing film of a preferred embodiment of the present invention, comprise the following steps:

[0027] (1) Provide a sphere 10; in this embodiment, the sphere 10 is a hollow sphere made of a metal shell, and the outer surface can be a primary color or coated with a base color, which can be white or silver, etc.; the sphere 10 The size is set in advance according to the needs, such as spheres with diameters of 60mm, 70mm, and 80mm;

[0028] (2) Make film, make different films according to the patterns corresponding to different colors; classify the colors according to the selected color pictures to be printed, and design the corresponding films according to the patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com