Multifunctional bar forming mold structure of fin mold

A multi-functional, finned die technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to disassemble, single function of the sliver die, and the overall structure is not independent, and achieves good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

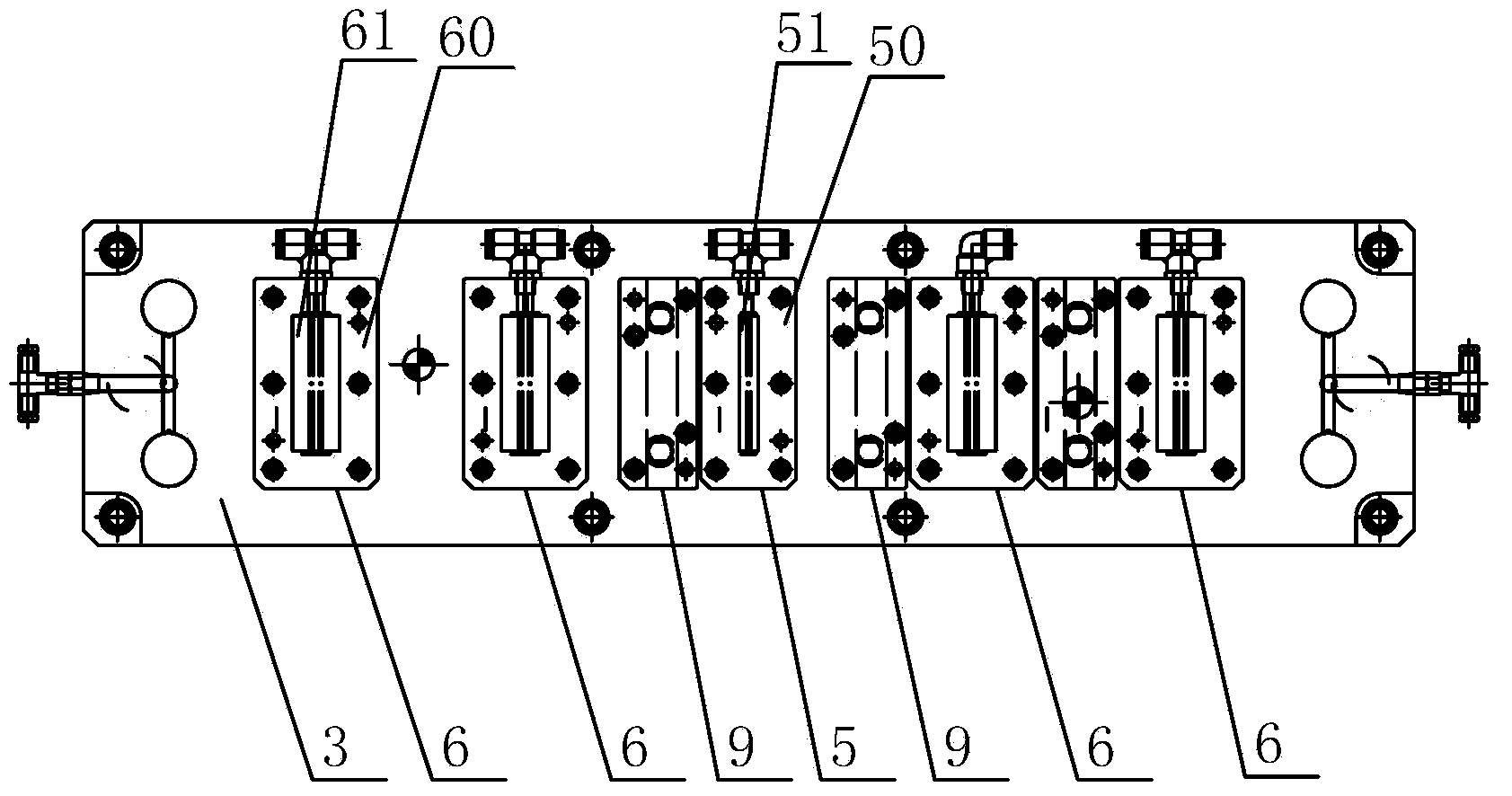

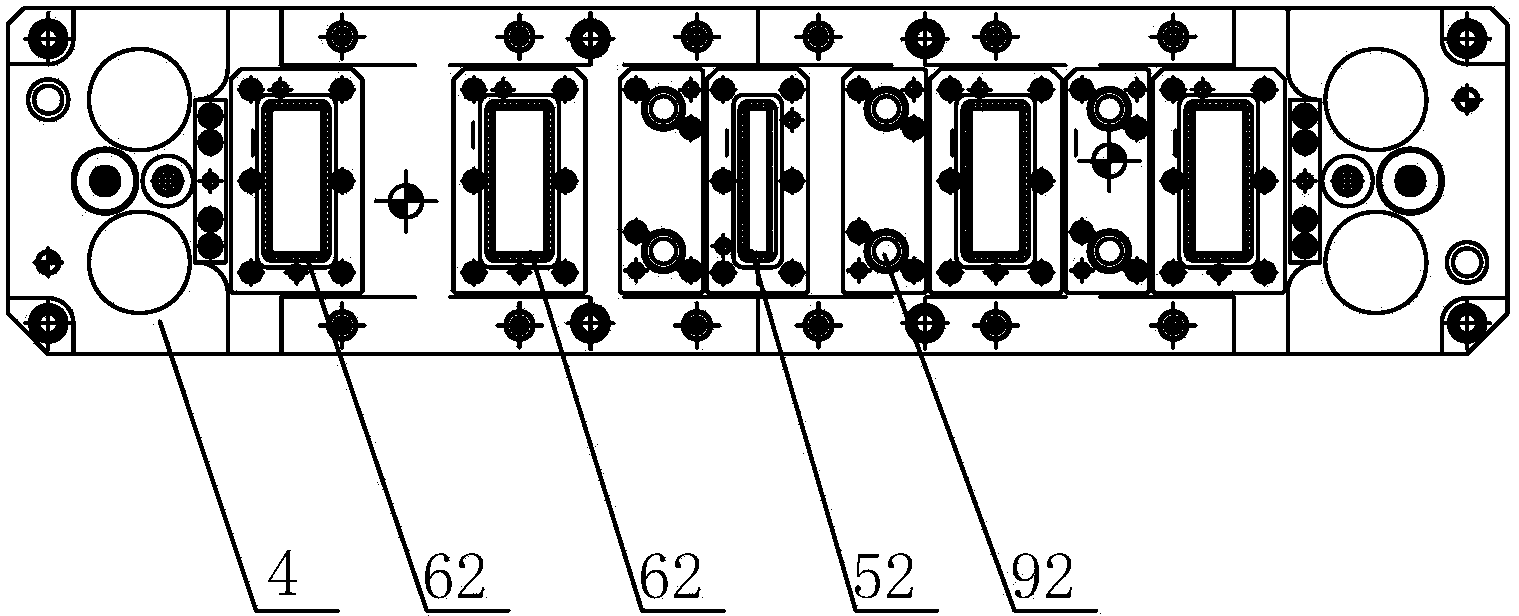

[0016] see Figure 1 to Figure 3 As shown in the figure, in this embodiment, a finned mold multi-functional slitting mold structure includes an upper template 1 and a lower template 2, a punch fixing plate 3 is installed on the bottom surface of the upper template 1, and the lower template 2 is The end face is provided with a female die fixing plate 4, and a set of slitting sub-moulds 5 are arranged between the male die fixing plate 3 and the female die fixing plate 4. The punch fixing plate 50 is provided with a slit punch 51 on the slotted punch fixing plate 50 , and the slotted punch 52 is arranged on the female mould fixing plate 4 correspondingly. And between the punch fixing plate 3 and the female die fixing plate 4, two sets of edge cutting sub-dies 6 are provided on both sides of the slitting sub-die 5, bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com