Deflection adaptive compensation type mechanical servo numerical control bending machine

A self-adaptive compensation and bending machine technology, applied in the field of bending machines, can solve the problems of straightness, uneven angle creases, high cost and high price of processing bending, and achieve absolute synchronization and high power utilization. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

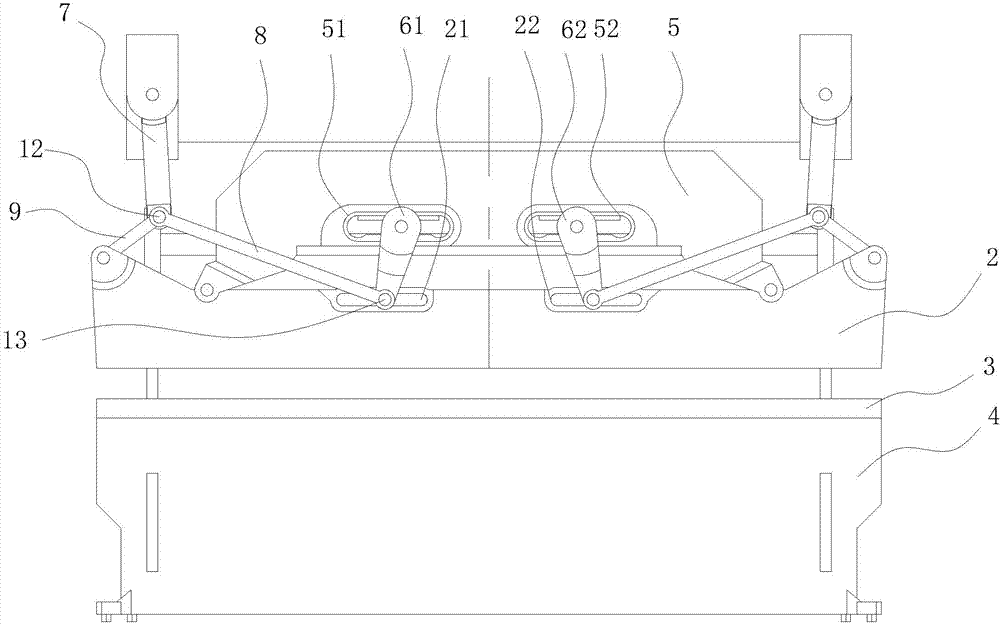

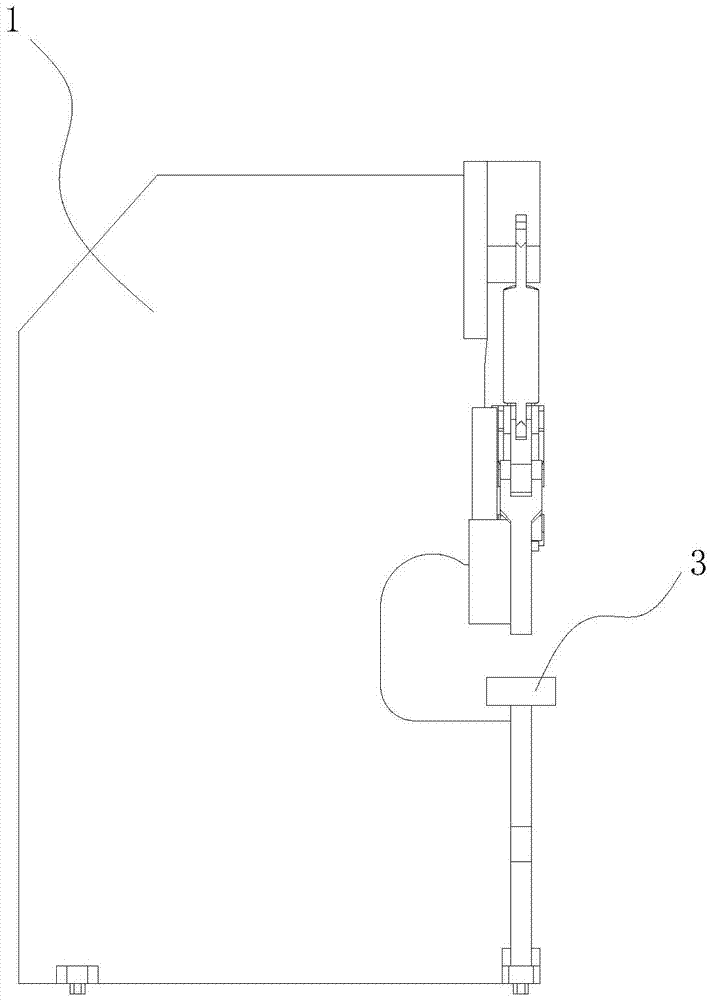

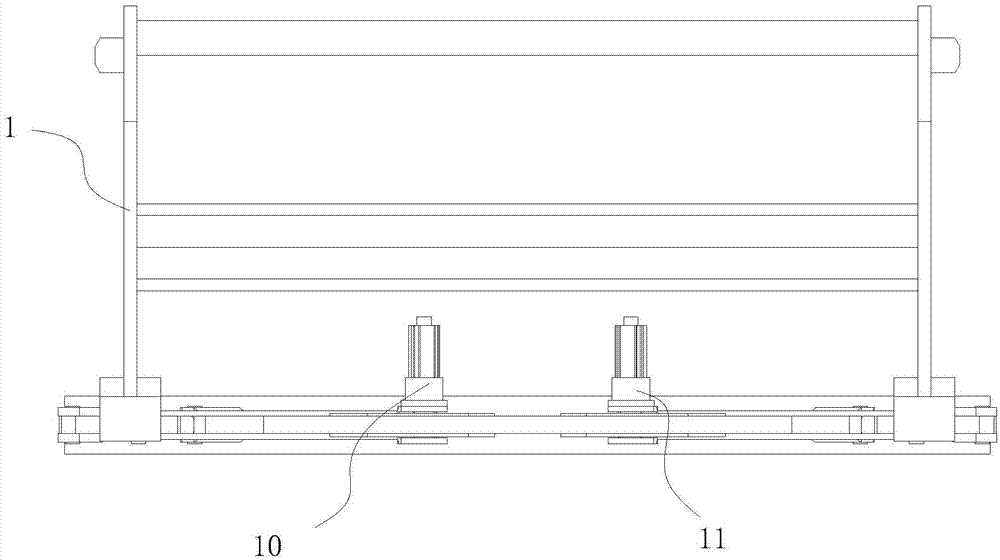

[0041] The invention as Figure 1-11 As shown, the bending machine includes a fuselage 1, a slider 2, a workbench 3 and a deflection compensation device; the deflection compensation device is connected to the slider 2, and the workbench 3 is set on the lower vertical plate 4;

[0042] The deflection compensation device includes a compensation beam 5, a pair of servo motors 10, a pair of driving arms (a driving arm 1 61 and a driving arm 2 62), a long connecting rod 8, a small connecting rod 9 and a swing arm 7;

[0043] The two lower corners of the compensation beam 5 are respectively hinged on the top edge of the slider 2, and the middle part of the compensation beam 5 is symmetrically provided with a pair of elongated chute one 51 and chute two 52, the slider 2 A pair of elongated chute 21 and chute 4 22 are symmetrically arranged on the top, the chute 1 51 is on the same side as the chute 3 21, and the chute 2 52 is on the same side as the chute 4 22;

[0044] The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com