Sweeping method of LNG tank car before unloading

A tank car and corresponding flange technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. problem, to achieve the effect of clean and small purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

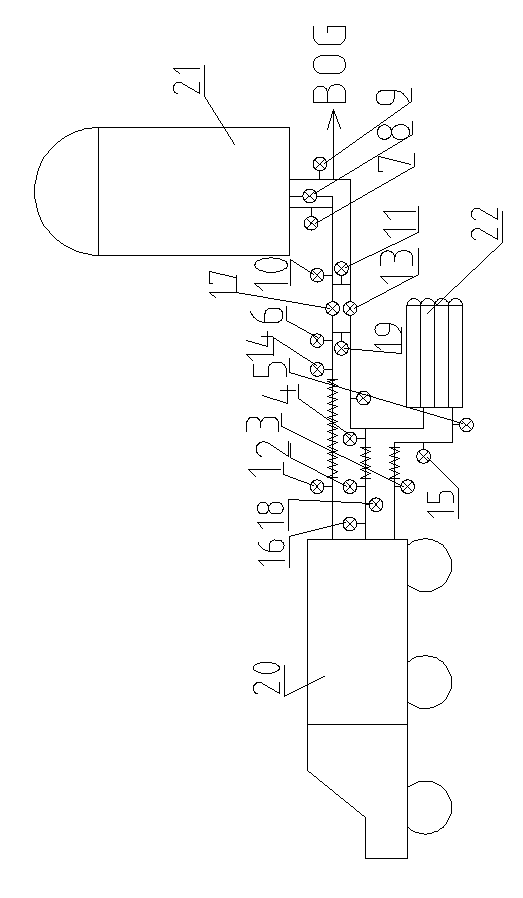

[0010] As can be seen in Figure 1, the three pipelines of the LNG tanker 20 are respectively connected to the liquid outlet pipeline, the gas phase pipeline and the self-pressurized liquid phase pipeline; The pipe is connected to the pipe network, and the rear end of the hose is sequentially connected to the first liquid inlet discharge valve 14 of the unloading platform, the first liquid inlet control valve 6 of the unloading platform, the one-way valve 17 of the liquid inlet pipeline, the main liquid inlet control valve 10 of the storage tank, and the first liquid inlet control valve of the unloading platform. The liquid inlet control valve 7 on the left pipeline of the tank is connected to the storage tank 21; the gas phase pipeline is connected to the gas phase pipeline release valve 16 of the tank car on the LNG tank car 20, and the self-pressurized gas phase control valve 2 of the tank car is connected to the hose through the flange Connected to the pipe network, the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com