Texturing method of monocrystalline semiconductor substrates to reduce incident light reflectance

A single crystal semiconductor, texture technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, crystal growth and other directions, can solve problems such as reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Three doped monocrystalline silicon wafers (from SolarGiga) had n+ doped regions on the front or emitter layer and pn junctions below the emitter layer. The above-mentioned wafers were immersed in a large liquor ratio texturing solution in an 18 liter falcon line. The formulation of the texture solution is shown in Table 1.

[0060] Table 1

[0061] components

content

0.5wt%

6wt%

[0062] 1,4-Butanediol 2

0.5wt%

water

93wt%

[0063] 1 Weight average molecular weight=192g / mol; 2 Flash point = 121°C

[0064] Flash point=140.5℃

[0065] Boiling point=268℃

[0066] Each wafer was weighed prior to texturing. The aqueous texturing solution was 80°C. No nitrogen sparging. The solution was manually stirred. The pH of the texturing solution was 13. During the texturing process, the dissolved oxygen content was measured using a D0202G2-Wire Dissolve...

Embodiment 2

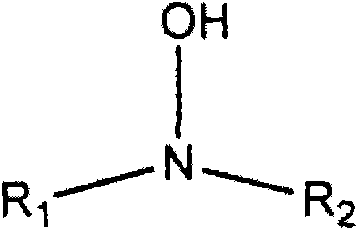

[0073] The method described in Example 1 was repeated using another three doped silicon single crystal semiconductor wafers. In addition to the components in Table 1, the formulation of the texturing solution included N-isopropylhydroxylamine. The formulation of the texture aqueous solution is shown in Table 3.

[0074] table 3

[0075] components

content

0.5wt%

6wt%

1,4-Butanediol

0.5wt%

N-isopropylhydroxylamine 3

0.017wt%

water

92.983wt%

[0076] 3 Hydroguard TM1-15 (Available from The Dow Chemical Company, Midland, MI, USA)

[0077] Each wafer was weighed before and after texturing. The aqueous texturing solution was 80°C. No nitrogen sparging. The solution was manually stirred. The pH of the texturing solution was 13. The results are shown in Table 4.

[0078] Table 4

[0079]

[0080] Addition of N-isopropylhydroxylamine reduces the oxygen c...

Embodiment 3

[0082] One of the two texturing solutions shown in Table 5 textured two doped monocrystalline silicon semiconductor wafers respectively.

[0083] table 5

[0084] components

Solution 1

Solution 2

1.2% bv

1.2% bv

6wt% (2ag / L)

6wt% (25g / L)

1,4-Butanediol

0.3% bv

0.3% bv

N-isopropylhydroxylamine

0

0.017wt%

water

margin

margin

[0085] Each wafer was immersed in one of the above two texturing solutions for 10 minutes. The solution was kept at 80°C and the pH of the solution was 13. Without nitrogen sparging, the solution was manually stirred. The oxygen content at the beginning of the texture in each bath was measured using a D0202G2-Wire Dissolved Oxygen Analyzer. Solution 1 containing no N-isopropylhydroxylamine had an oxygen content of 3.3 ppm. In contrast, solution 2 containing N-isopropylhydroxylamine had an oxygen content of 0 ppm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com