Reliable arcing system of non-polarity high-voltage direct current contactor

A high-voltage direct current, contactor technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of inability to withstand reverse current switching and low switching life, and achieve compact structure, reliable arc extinguishing, and arc cooling speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

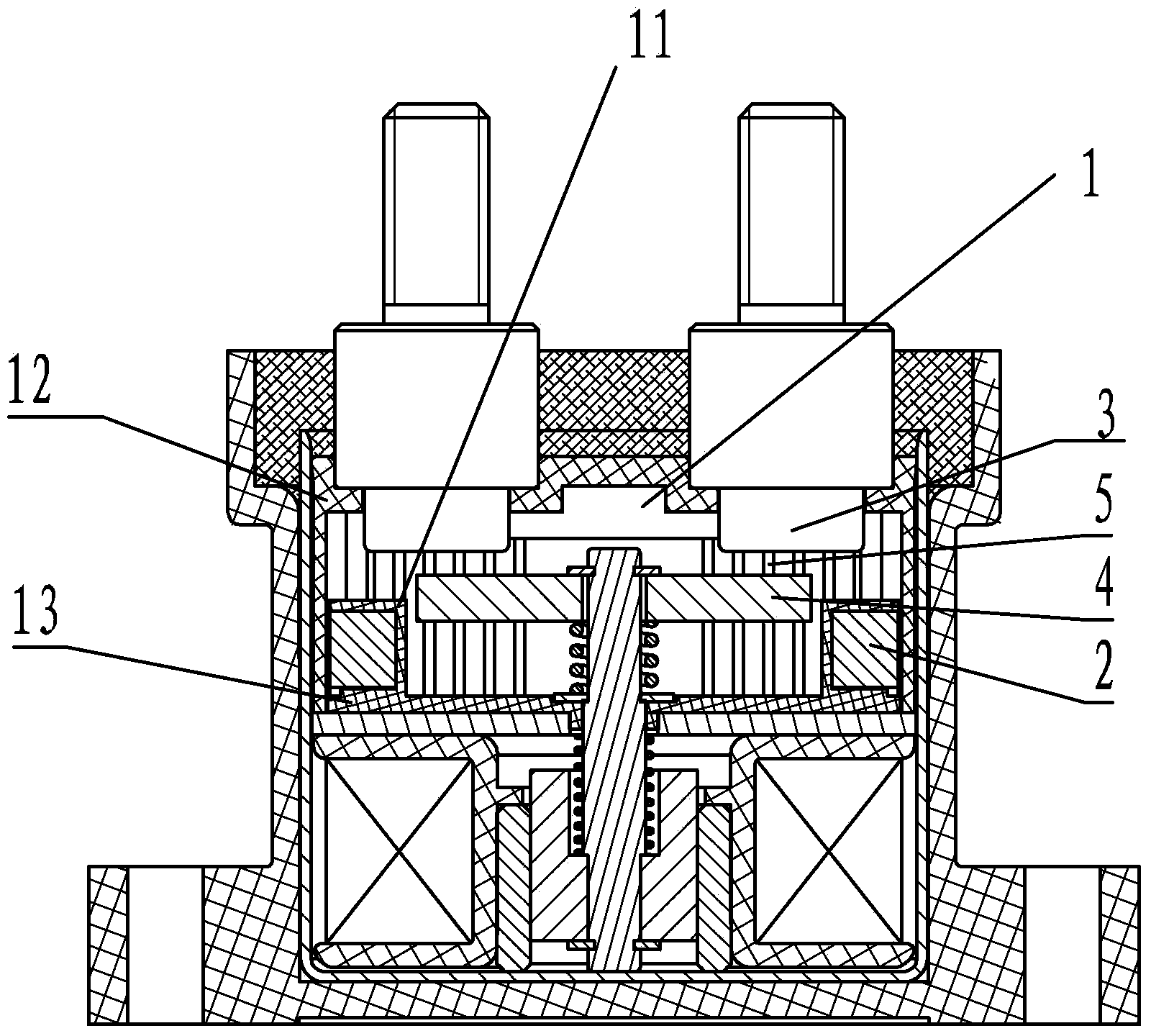

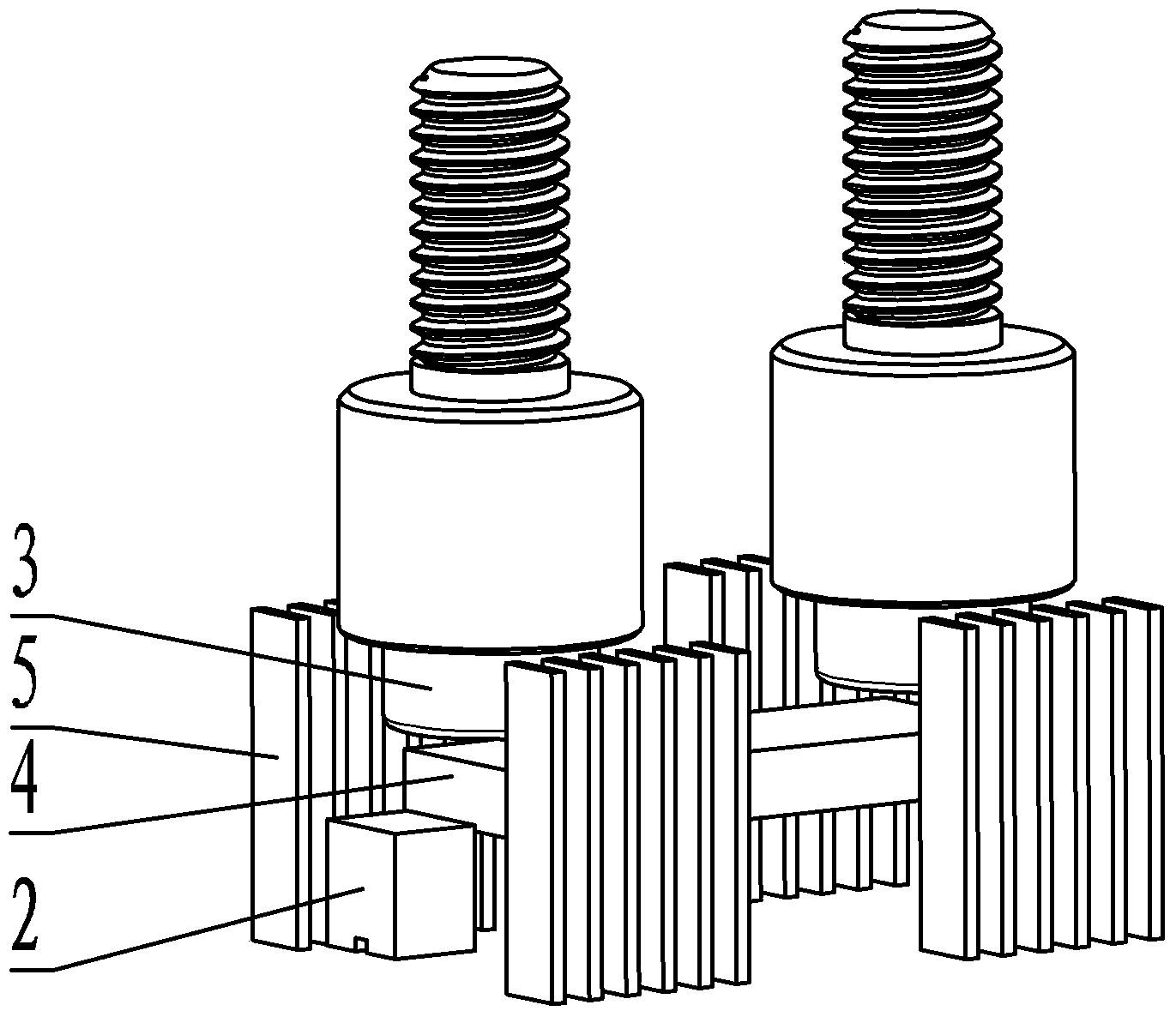

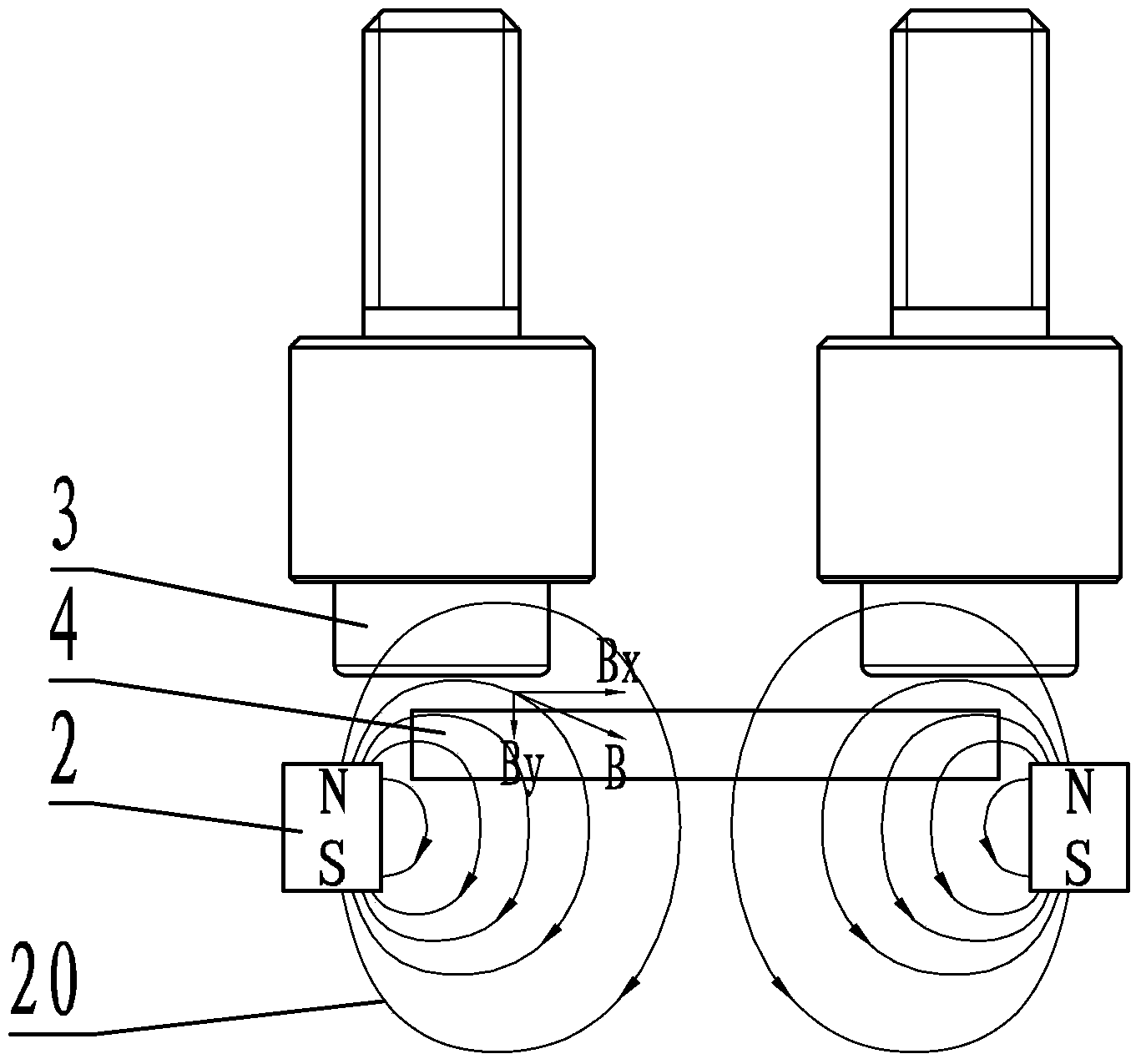

[0030] see figure 1 , figure 2 As shown, a reliable arc-extinguishing non-polar high-voltage DC contactor arc-extinguishing system of the present invention includes a sealed contact chamber 1 and two permanent magnets 2 of a contactor; Two static contacts 3 and two normally open movable contacts 4 are installed in the activity, and the two movable contacts 4 and the two static contacts 3 are matched vertically respectively. In this embodiment, the two movable contacts The points are connected together to form a bridge-type moving contact piece. Of course, the two moving contacts can also be a split structure; the two permanent magnets 2 are respectively installed on the extension line side of the two static contact lines, that is, two The permanent magnet 2 is installed symmetrically on both sides of the area between the two static contacts. In this embodiment, two permanent magnets are used. Of course, it is also possible to arrange more permanent magnets on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com