Alkali developing-type photosensitive resin composition and dry film as well as cured material and printed circuit board

A photosensitive resin, alkali developing type technology, applied in the formed alkali developing type photosensitive resin composition, dry film, curing field, can solve problems such as adverse effects, achieve good characteristics, excellent storage stability, biodegradability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

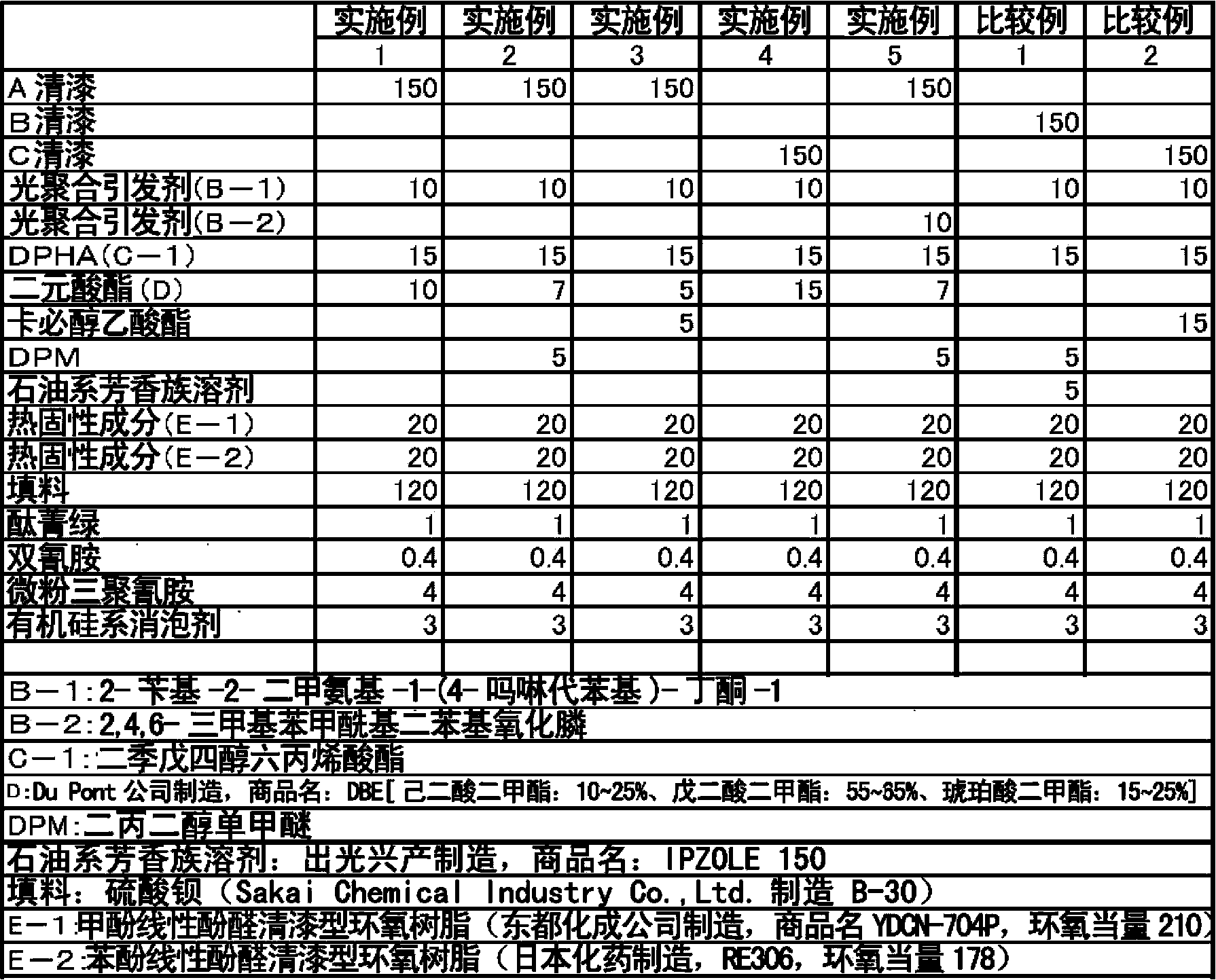

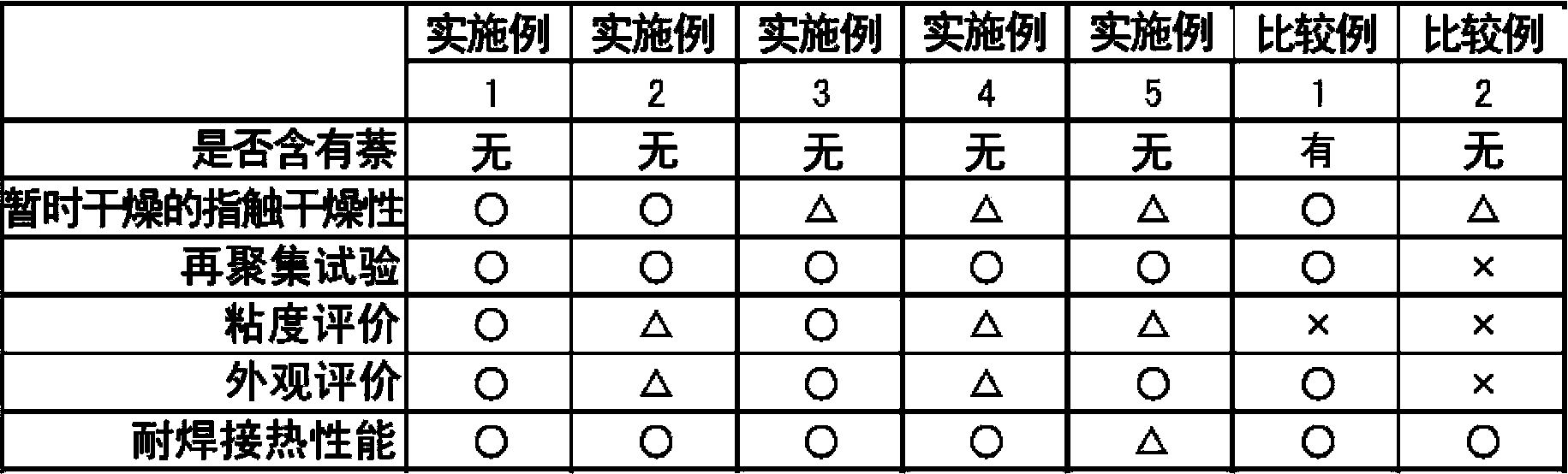

Synthetic example 1

[0114] Put 214 parts of EPICLON N-695 (manufactured by DIC Corporation, epoxy equivalent = 214) of cresol novolak type epoxy resin into a four-necked flask equipped with a stirrer and reflux condenser, and add 103 parts of carbitol Acetate, 103 parts of dibasic acid ester solvent (manufactured by Du Pont, trade name: DBE [dimethyl adipate: 10~25%, dimethyl glutarate: 55~65%, dimethyl succinate Esters: 15~25%]) and heated to dissolve. Next, 0.1 part of hydroquinone as a polymerization inhibitor and 2.0 parts of triphenylphosphine as a reaction catalyst were added. This mixture was heated at 95-105 degreeC, and 72 parts of acrylic acid were dripped slowly, and it was made to react for 16 hours. Cool the obtained reaction product to 80~90°C, add 91.2 parts of tetrahydrophthalic anhydride, react for 8 hours, take it out after cooling. The carboxyl group-containing photopolymerizable unsaturated compound thus obtained had a nonvolatile content of 65%, and an acid value of solid m...

Synthetic example 2

[0116] Put 214 parts of EPICLON N-695 (manufactured by DIC Corporation, epoxy equivalent = 214) of cresol novolak type epoxy resin into a four-necked flask equipped with a stirrer and reflux condenser, and add 103 parts of carbitol Acetate, 103 parts of petroleum-based aromatic solvents (manufactured by Idemitsu Kosan, trade name: IPZOLE 150) were heated and dissolved. Next, 0.1 part of hydroquinone as a polymerization inhibitor and 2.0 parts of triphenylphosphine as a reaction catalyst were added. This mixture was heated at 95-105 degreeC, and 72 parts of acrylic acid were dripped slowly, and it was made to react for 16 hours. Cool the obtained reaction product to 80~90°C, add 91.2 parts of tetrahydrophthalic anhydride, react for 8 hours, take it out after cooling. The carboxyl group-containing photopolymerizable unsaturated compound thus obtained had a nonvolatile content of 65%, and an acid value of solid matter of 87.5 mgKOH / g. Hereinafter, the solution of this reaction ...

Synthetic example 3

[0118] Put 214 parts of EPICLON N-695 (manufactured by DIC Corporation, epoxy equivalent = 214) of cresol novolak type epoxy resin into a four-necked flask equipped with a stirrer and reflux condenser, and add 103 parts of carbitol Acetate, 103 parts of dipropylene glycol monomethyl ether (manufactured by Toho Chemical Industry, trade name: Hissolve DPM) were dissolved by heating. Next, 0.1 part of hydroquinone as a polymerization inhibitor and 2.0 parts of triphenylphosphine as a reaction catalyst were added. This mixture was heated at 95-105 degreeC, and 72 parts of acrylic acid were dripped slowly, and it was made to react for 16 hours. Cool the obtained reaction product to 80~90°C, add 91.2 parts of tetrahydrophthalic anhydride, react for 8 hours, take it out after cooling. The carboxyl group-containing photopolymerizable unsaturated compound thus obtained had a nonvolatile content of 65%, and an acid value of solid matter of 87.5 mgKOH / g. Hereinafter, the solution of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com