Clamp for threaded fastener proof load tests

A technology for threaded fasteners and guaranteed load, applied in the field of threaded fastener testing devices, can solve problems such as large error in test values, and achieve the effects of prolonging service life, preventing corrosion and accurate test values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

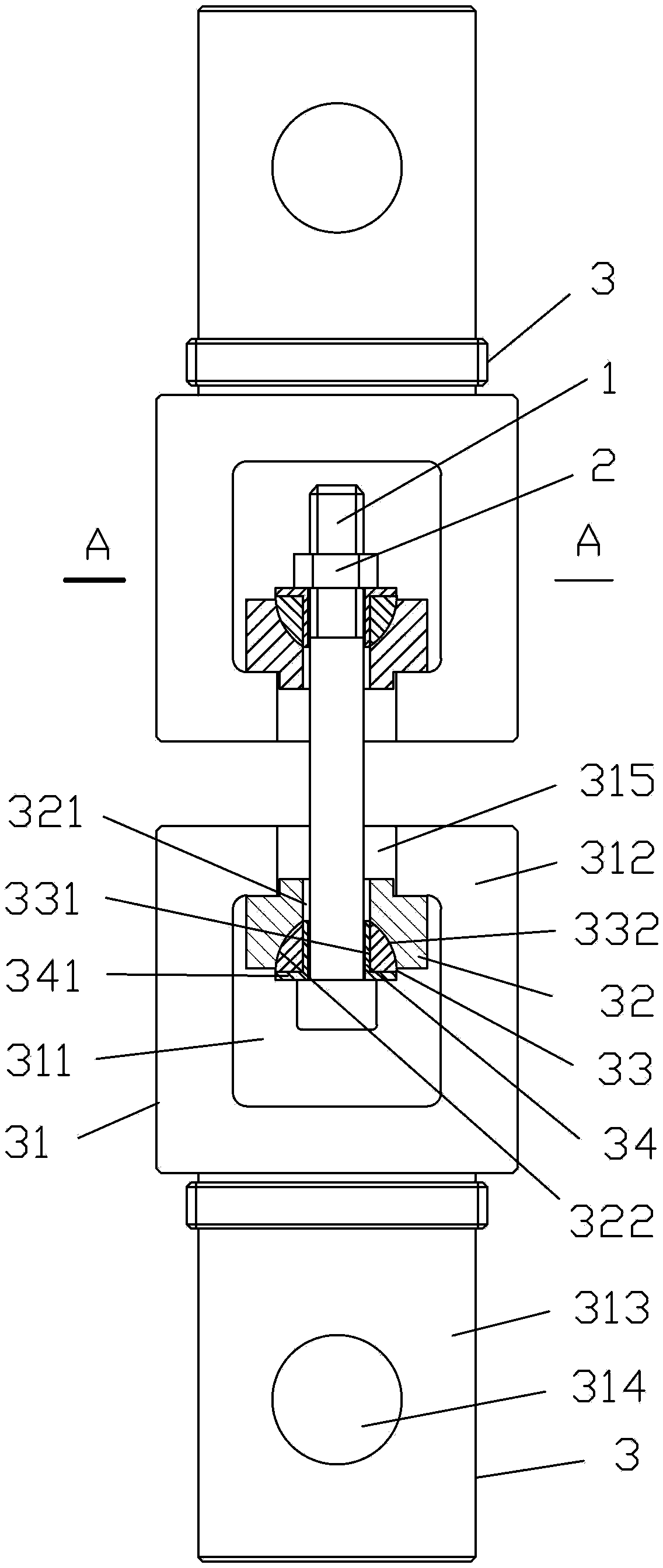

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

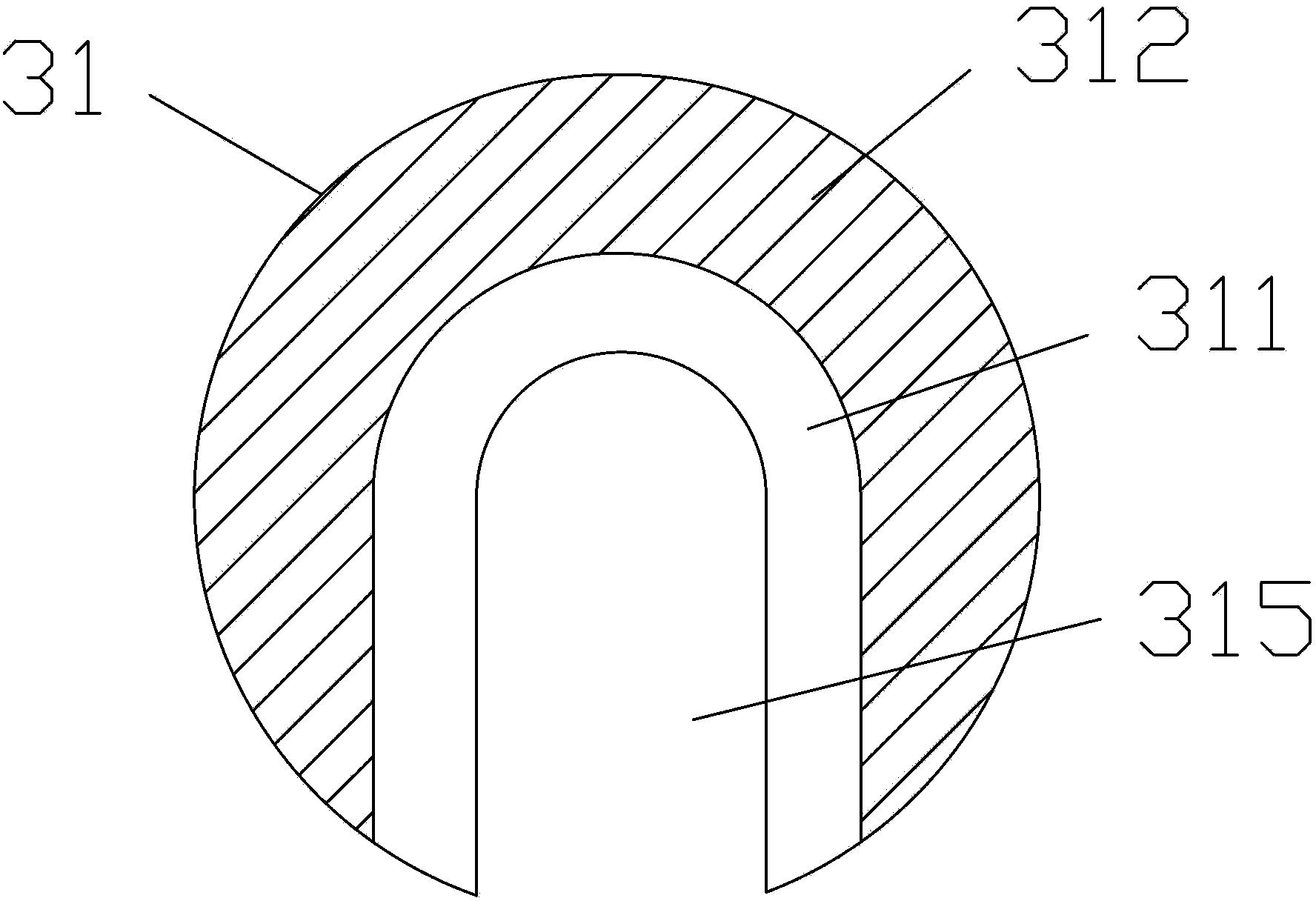

[0017] as attached figure 1 , attached figure 2 Shown: a proof load test fixture for threaded fasteners, including two symmetrically arranged chucks 3, several standard bolts 1 of different specifications, and several standard nuts corresponding to several standard bolts 1 one by one (in the figure not shown); the chuck 3 includes a chuck body 31, a flat pad 32 with a through hole 321, a follower pad 33 with a middle hole 331 whose aperture is smaller than the aperture of the through hole 321, and several sleeves with one end Adjusting washer 34 with retaining ring 341; the inner diameters of several adjusting washers 34 correspond to several standard bolts 1 one by one; the outer diameter of one adjusting washer 34 is in transition fit with the inner diameter of another adjusting washer 34 sleeved outside; the outermost The outer diameter of an adjusting washer 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com