Oxygen inhalator calibrating apparatus

An inhaler and calibrator technology, which is applied in the field of oxygen inhaler calibrator, can solve the problems of low verification work quality, low verification accuracy, and high work intensity, and achieves light weight, fast and accurate measurement, and reduced work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

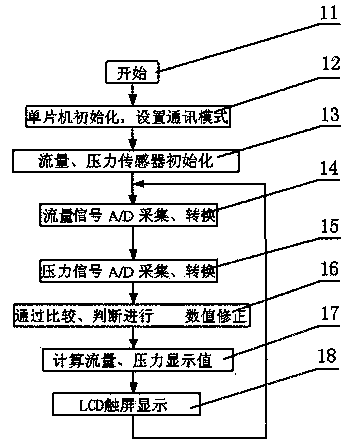

Image

Examples

Embodiment Construction

[0043] The gas input end of the flow sensor 2 is threadedly connected to the gas output end of the gas transmission quick-connect conduit 1, and the output end of the flow sensor 2 is threadedly connected to the gas input end of the three-way connection block 3, and the flow sensor 2 passes through the A / D conversion module A serial port communication lead is connected with the flow data acquisition module of the 32-bit single-chip microcomputer 7;

[0044] The threaded connection end of the low-pressure pressure sensor 5 is threadedly connected with one end of the tee connection block 3; the low-pressure pressure sensor 5 is connected with the low-pressure pressure data acquisition module of the 32-bit single-chip microcomputer 7 through the serial port communication wire of the A / D conversion module two;

[0045] The input end of the high-pressure pressure sensor 9 is used to be threadedly connected with the output end of the high-pressure gas source; the high-pressure pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com