Double planetary gear train type continuously variable automatic transmission mechanism

A dual-planetary gear train, automatic transmission technology, applied in the direction of vehicle transmission, gear transmission, transmission elements, etc., can solve the problems of obvious frustration, high cost, complex mechanism, etc.

- Summary

- Abstract

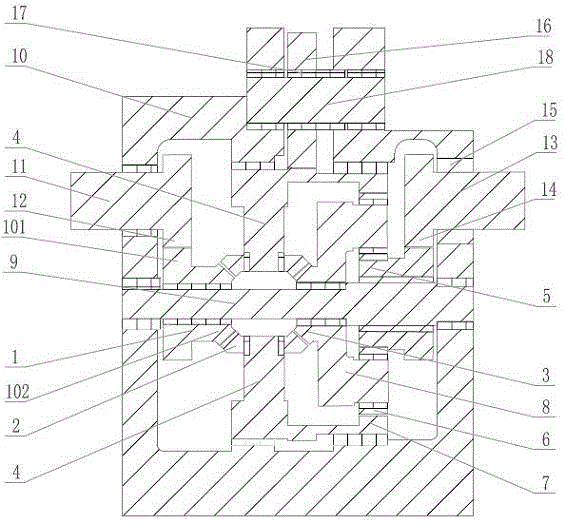

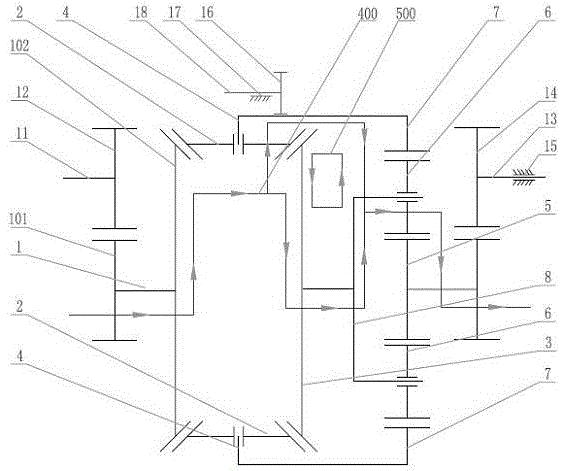

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

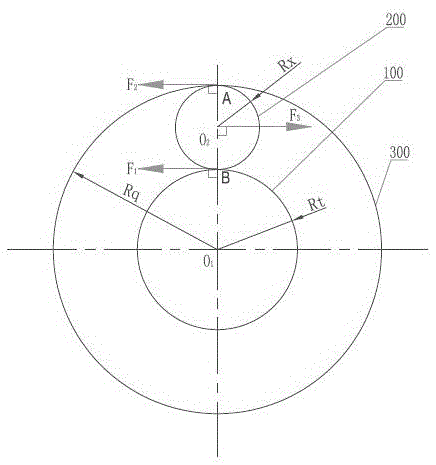

[0021] Now the letter and the symbol in the formula that the present invention adopts are described as follows.

[0022] Pr represents input power, Pc represents output power, Mr represents input torque, Wr represents input rotational angular velocity, Mc represents output torque, Wc represents output rotational angular velocity, and Mr and Wr are known constants, Pd represents output through the idle mechanism Power, Mz represents the intermediate torque, Wz represents the intermediate rotational angular velocity, Mz and Wz are intermediate free variables, a, b, a 1 , b 1 Both are constant coefficients, and Ps represents the power lost inside the transmission mechanism;

[0023] In a single planetary gear system, Wt represents the rotational angular velocity of the sun gear, Wx represents the rotational angular velocity of the planet carrier, Wq represents the rotational angular velocity of the ring gear, Rt represents the pitch circle radius of the sun gear, Rx represents t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com