Painting brush coating and roller coating integrated device

An integrated, coating technology, applied in the direction of architecture, building structure, etc., can solve the problems of high labor intensity, low work efficiency, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

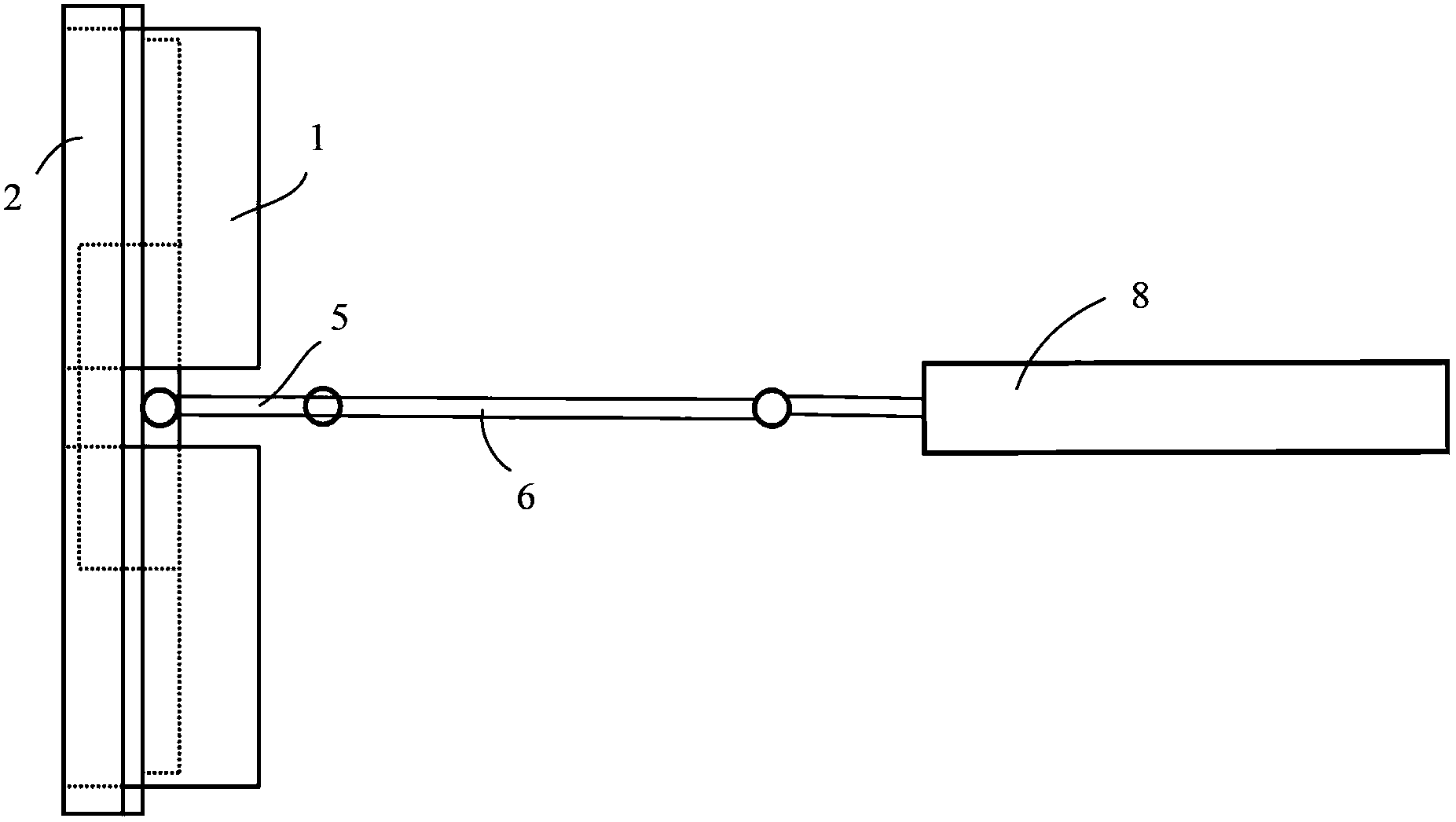

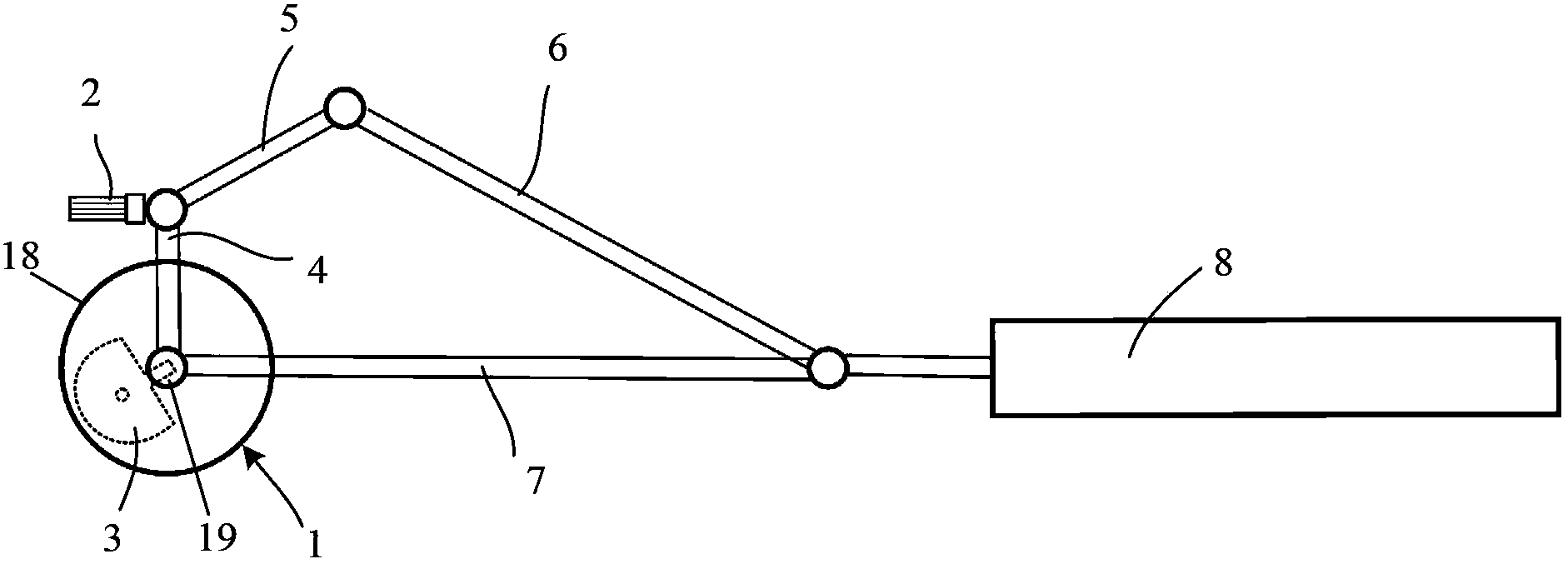

[0020] Such as figure 1 and figure 2 As shown, the paint roller brush integrated device includes a roller head 1 , a brush head 2 and a constant gravity balance device 3 . The drum 1 has a roller core 19 and a drum 18 supported by the roller core 19 freely rotatable (such as Figure 6 shown).

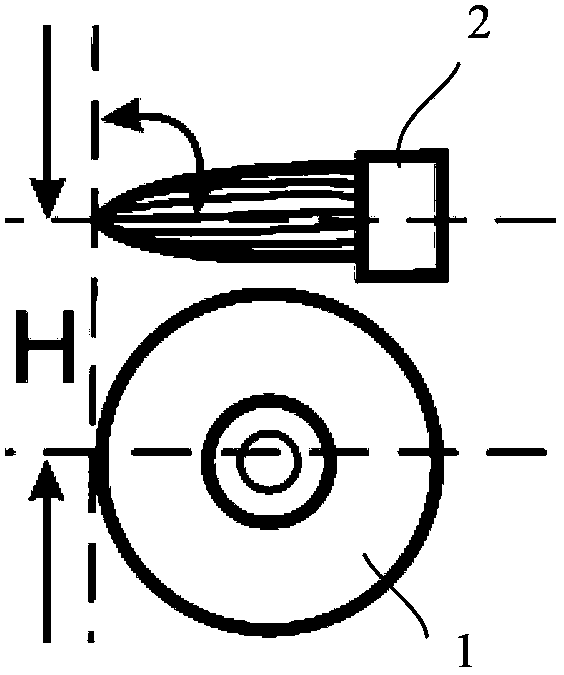

[0021] The working position of brush head 2 will be higher than cylinder 18, as Figure 4 As shown, the axis X1 of the brush head 2 is parallel to the axis X2 of the roller head 1, and the width of the brush head 2 is greater than the width B of the roller head 1, so that the two ends of the brush head 2 are relative to the roller head 1. Protrude at both ends. Because the amount of paint absorbed by the roller 18 is large, and the brushing effect of the brush 2 is delicate, so the roller head 1 is installed under the brush head 2. Evenly spit out, and the final brushing effect is completed by the brush head 2 installed on the top. The brush head 2 sweeps the paint spit out by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com