A gas meter movement

A gas meter and movement technology, which is applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of low assembly efficiency, short service life, and unstable installation of gas meters, so as to achieve non-deformation, ensure tightness, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

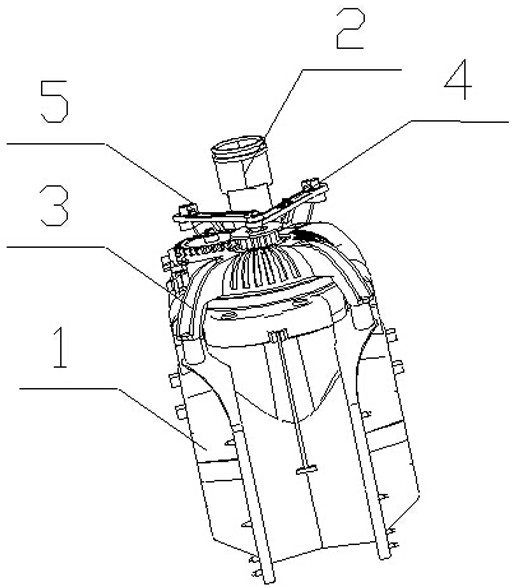

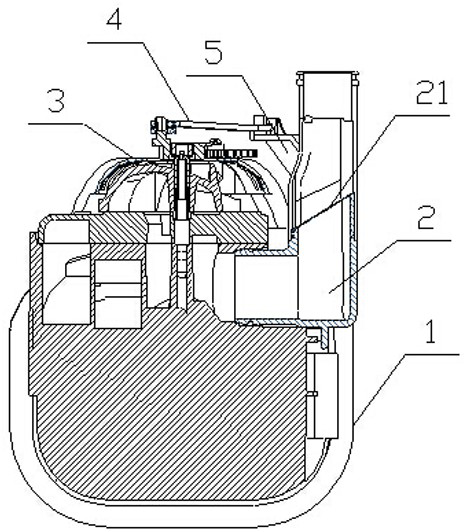

[0041] like Figure 1-Figure 6 As shown, a gas meter movement includes a movement body 1, a bridge 3, a vertical shaft 5, and a counter. The movement body 1 is provided with an air outlet pipe 2, and the movement body 1 includes a movement main body 11, a movement side The cover 12 has open ends 113 at both ends of the movement main body 11 , the movement side cover 12 is fixed at the open ends 113 at both ends of the movement main body 11 , and is provided between the movement main body 11 and the movement side cover 12 There is a membrane 114, and membrane gaskets 115 are arranged on both sides of the membrane 114. The membrane divides the cavity formed between the movement main body 11 and the movement side cover 12 into two parts, the movement main body 11 and the movement side cover 12. The upper end of the cavity formed between is provided with a valve grid 34, the valve grid 34 is provided with a valve cover 35, the valve cover 35 is provided with a gap, the bridge fram...

Embodiment 2

[0045] On the basis of the gas meter core described in Embodiment 1, it is further optimized. The air outlet pipe 2 is provided with an anti-reverse ventilation sheet 21, and the anti-reverse ventilation sheet 21 is arranged obliquely. The setting of this embodiment is to prevent The gas flows in the reverse direction, and at the same time, relative to the anti-reverse ventilation sheet 21 set horizontally, the inclined setting of the anti-reverse ventilation sheet 21 can ensure that when the flow is forward, a small airflow can push the anti-reverse ventilation sheet 21 away, which ensures the sensitivity of the device. sex.

Embodiment 3

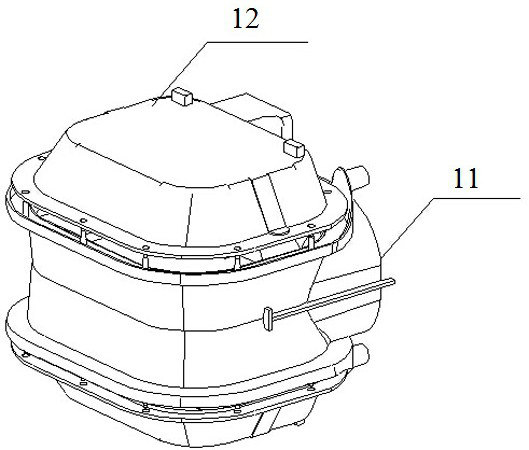

[0047] like Figure 7-Figure 8 As shown, further optimized on the basis of the gas meter core described in Embodiment 1, the fixing column 112 is sequentially set as a limit end 1121 and a mounting end 1122 from top to bottom. The diameter is smaller than the diameter of the installation end 1122 , the undercut 13 is a circular metal sheet, and an irregularly shaped through hole 131 is formed in the middle of the undercut 13 , and the minimum diameter of the through hole 131 is larger than the diameter of the limit end 1121 and smaller than the diameter of the limit end 1121 The diameter of the installation end 1122, the maximum diameter of the through hole 131 is larger than the diameter of the installation end 1122, the undercuts 13 are evenly distributed with several barbs 132 in the circumferential direction toward the center of the circle, which is convenient for the installation of the undercuts 13 and prevents the movement side cover 12 from being damaged. After pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com