Treatment method allowing plastic surface to have high metal texture

A processing method and high-metal technology, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of difference in metal feeling, failure to achieve metal texture, and rough surface effect of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

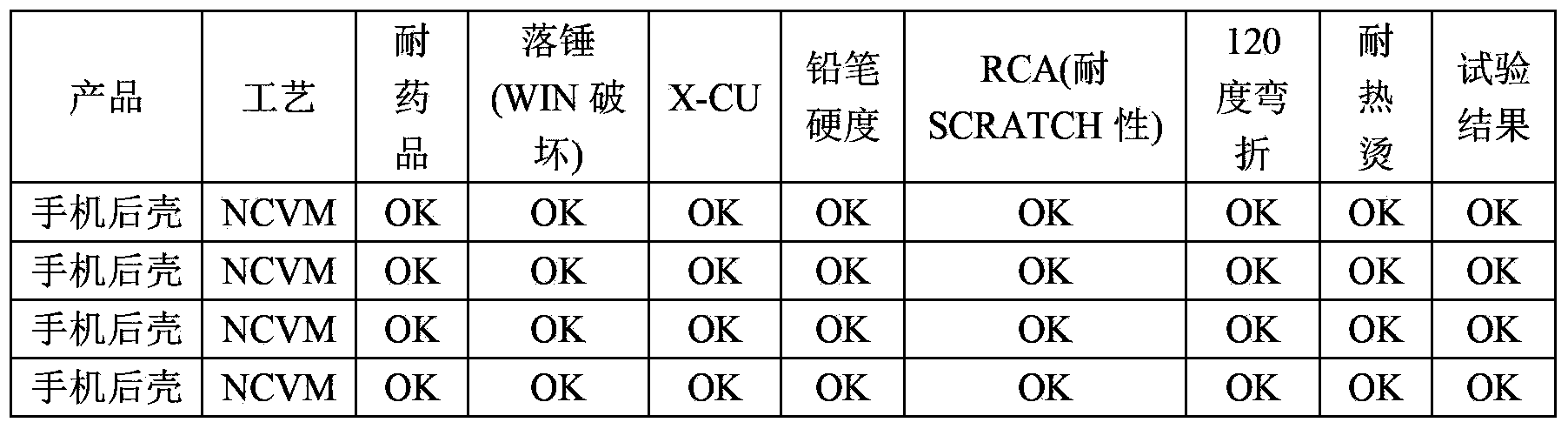

Examples

Embodiment Construction

[0015] The present invention will be further described below in combination with preferred embodiments.

[0016] The invention discloses a treatment method for making the plastic surface have a high metal texture. In a specific embodiment, it includes an ion bombardment step: placing a clean plastic product in a vacuum evaporation coating chamber, and performing ion bombardment on the surface of the plastic product , the parameters of the ion bombardment are as follows: First, the vacuum in the vacuum evaporation coating chamber is pumped to 2.0×10 -2 ~3.0×10 -2 Pa, filled with argon gas, the flow rate of argon gas is kept at 800-1300 sccm, so that the vacuum degree in the vacuum evaporation coating chamber reaches 2-3 Pa, and the argon gas is ionized at a voltage of 2-2.4KV and a current of 0.8-1A , and bombard the surface of the plastic product, the bombardment time is 150 to 180 seconds; after the ion bombardment is completed, the vacuum degree in the vacuum evaporation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com