Titanium alloy product having high strength and excellent cold rolling property

A high-quality titanium alloy technology, applied in the field of high-strength and excellent cold-rolled titanium alloy materials, can solve the problems of low processability, high-priced alloy elements, and cost of titanium alloy materials, and achieve high productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

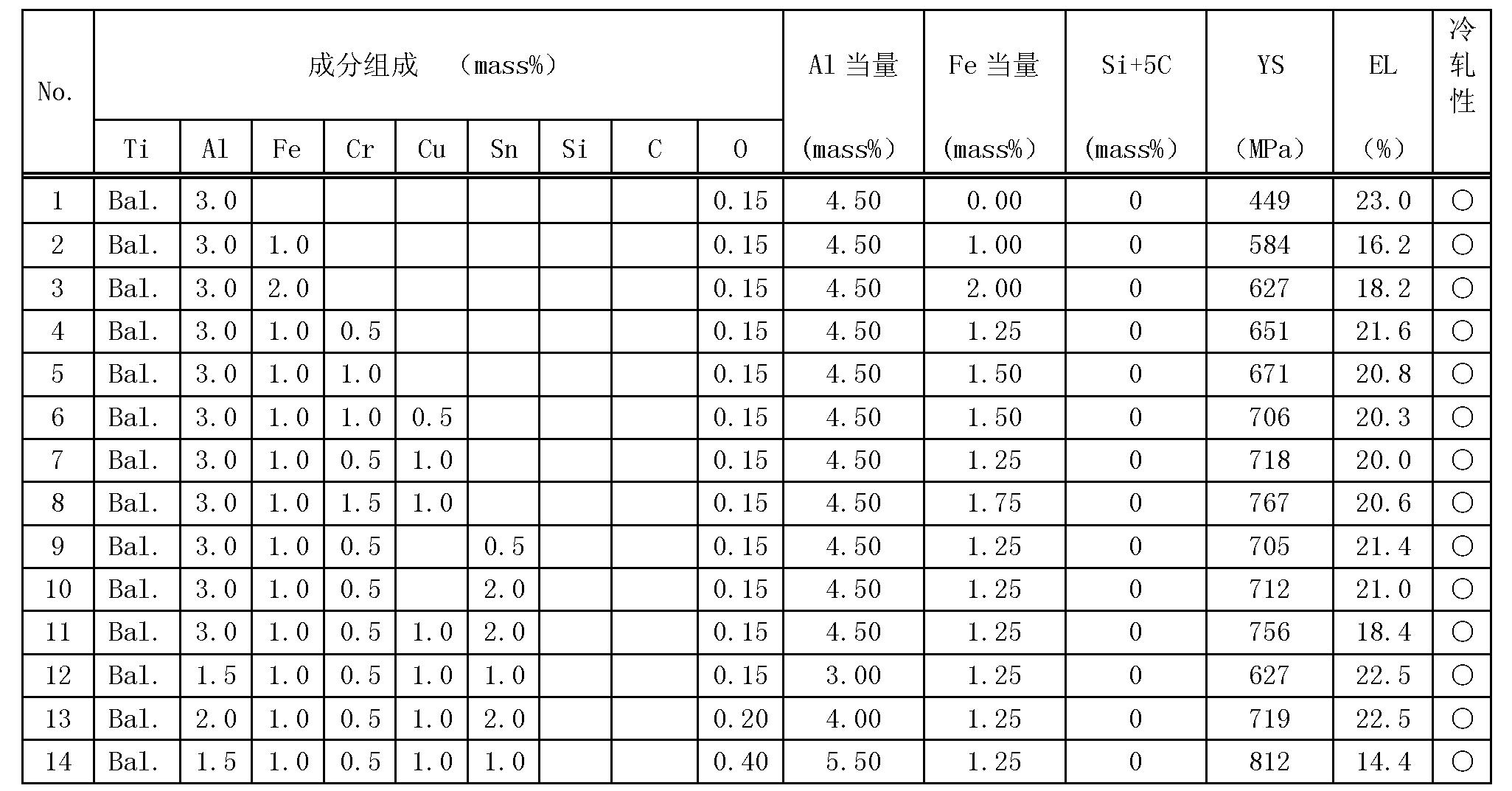

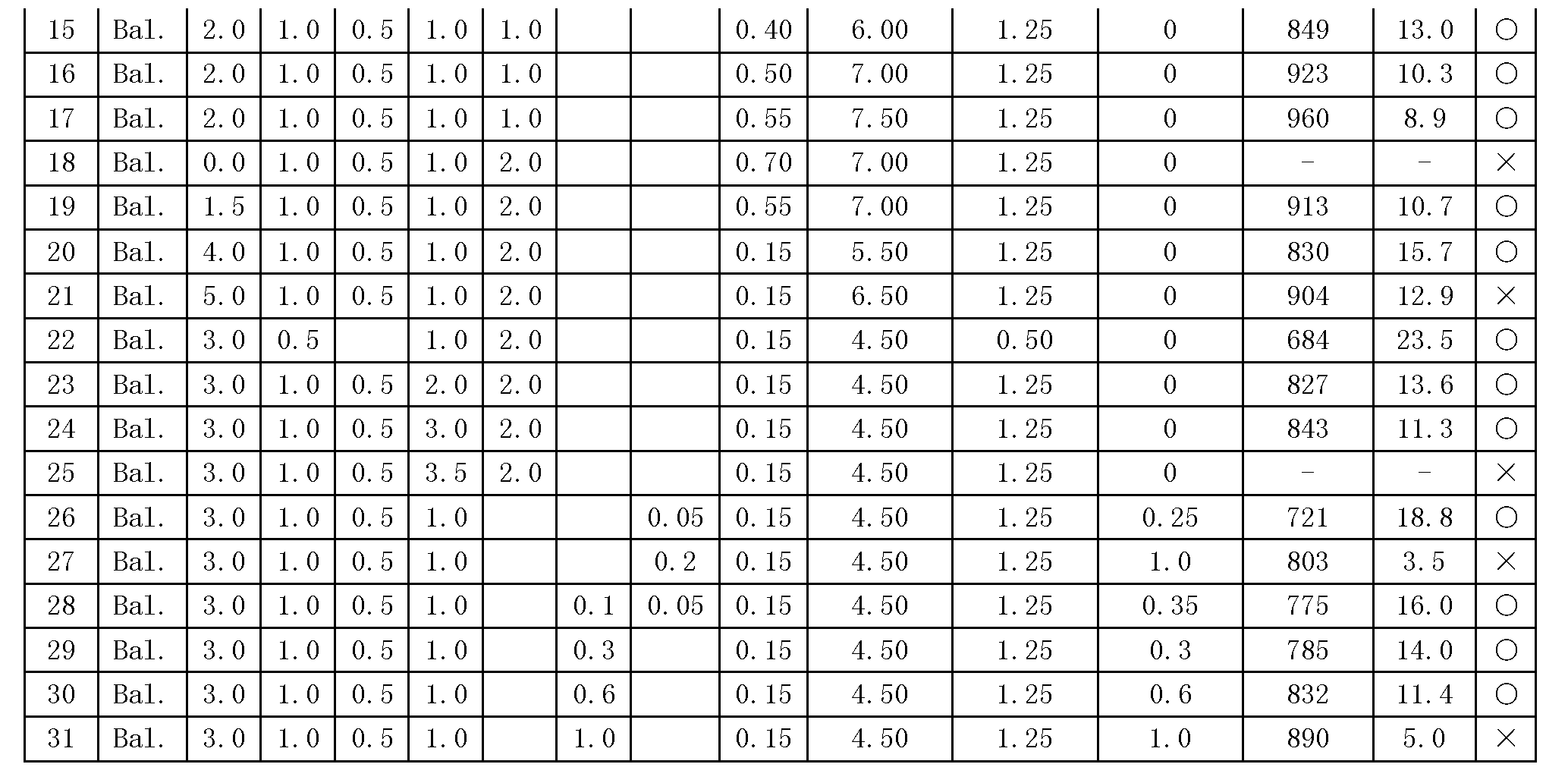

Image

Examples

Embodiment Construction

[0017] In order to solve the above-mentioned problems, the present inventors aimed at an α+β-type titanium alloy, and obtained an α-phase stabilizing element and a eutectoid β-phase stabilizing element without the above-mentioned high-priced alloy elements. High strength, cold rollability and workability (elongation equal to or higher than Ti-6Al-4V alloy) all titanium alloy materials have been intensively studied.

[0018] As a result, it was found that the means shown in the following (1) to (3) are particularly effective, leading to the present invention.

[0019] (1) The range of Al equivalent represented by Al and O as α-phase stabilizing elements: Al+10O (oxygen) is specified. Among them, Al plays an effective role in improving the strength, so it is necessary, but on the other hand, because it is also an element that causes a reduction in cold rolling and elongation, the content (Al alone) is higher than that of Ti-6Al-4V alloys, etc. There are few general-purpose allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com