Continuous solid fermentation ethanol production device having self-control system and technology thereof

A solid-state fermentation and solid-state fermenter technology, which is applied in solid-phase fermentation bioreactors, specific-purpose bioreactors/fermenters, fermentation, etc. Deal with high cost problems to achieve the effect of reducing production costs, saving manpower, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

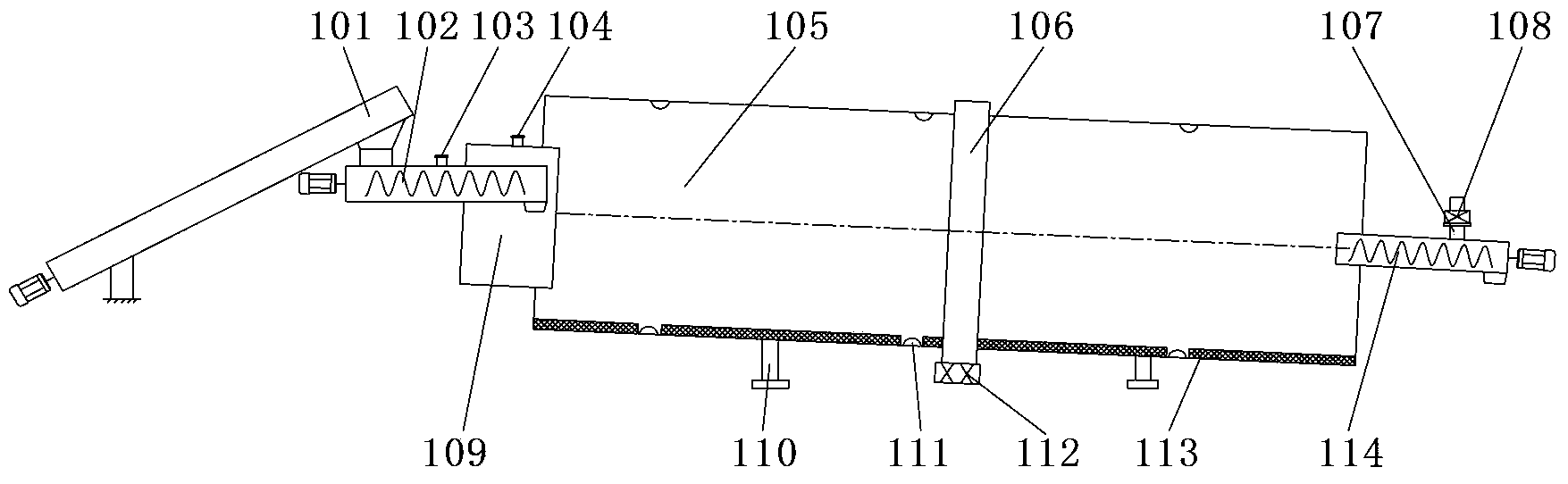

[0047] Embodiment 1 (continuous fermentation)

[0048] Harvest mature sweet sorghum stalks, use sweet sorghum stalks with a water content of 70%, a total sugar content of 11%, and a reducing sugar content of 7% as raw materials, and crush them into filaments with a diameter of 1-2 mm and a length of less than 30 mm. At the same time, CGMCC1949 strains are added to the screw feeding feeder, mixed with crushed materials, and then continuously fermented in a continuous solid-state fermenter. The inoculum amount of fermentation bacteria is 10% (V / W), adjust the operating parameters, keep the temperature in the tank at 25-40°C, the fermentation time is 24 hours, and the rotation speed of the fermentation tank is 0.25rpm. After fermentation, the yield of ethanol was 91.2%, and the conversion rate of total sugar was 94.2%.

Embodiment 2

[0049] Embodiment 2 (continuous fermentation)

[0050] Harvest mature sweet sorghum stalks, use sweet sorghum stalks with a water content of 70%, a total sugar content of 12%, and a reducing sugar content of 8% as raw materials, and crush them into filaments with a diameter of 1-2 mm and a length of less than 30 mm. At the same time, CGMCC1949 strains are added to the screw feeding feeder, mixed with crushed materials, and then continuously fermented in a continuous solid-state fermenter. The inoculum amount of fermentation bacteria is 15% (V / W), adjust the operating parameters, keep the temperature in the tank at 25-40°C, the fermentation time is 30 hours, and the rotation speed of the fermentation tank is 0.1rpm. After fermentation, the yield of ethanol was 92.3%, and the conversion rate of total sugar was 96.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com