Matt polyurethane wood floor paint with formaldehyde removing function and preparation method thereof

A polyurethane and wood flooring technology, which is applied in the field of matte varnish, can solve the problems of unfavorable home environment and health, and achieve the effect of excellent aldehyde removal function, good adhesion, and wear-resistant coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] A matte polyurethane wood floor paint with formaldehyde removal function is prepared by mixing a hydroxyl component and an NCO component in a mass ratio of 1:0.8-1.2, wherein the hydroxyl component and the NCO component are respectively composed of the following components and weights The ratio of servings is prepared by:

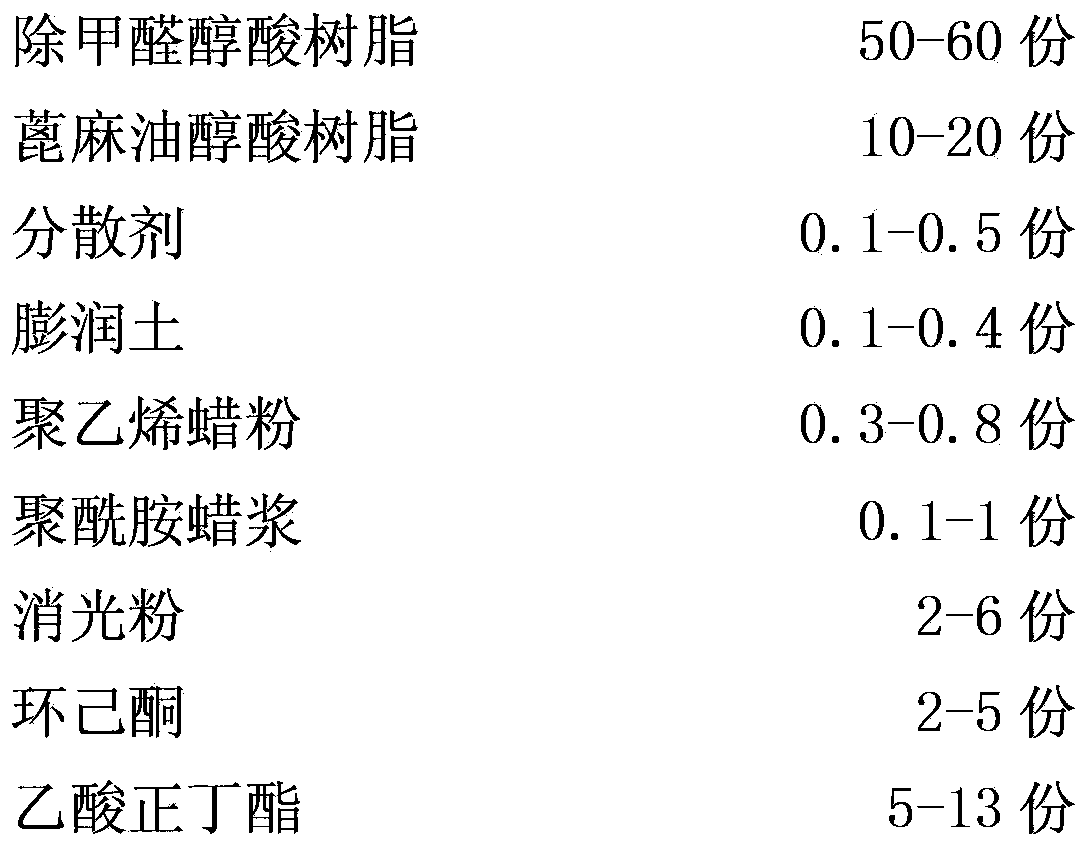

[0029] Wherein the hydroxyl components and parts by weight ratio are as follows:

[0030]

[0031]

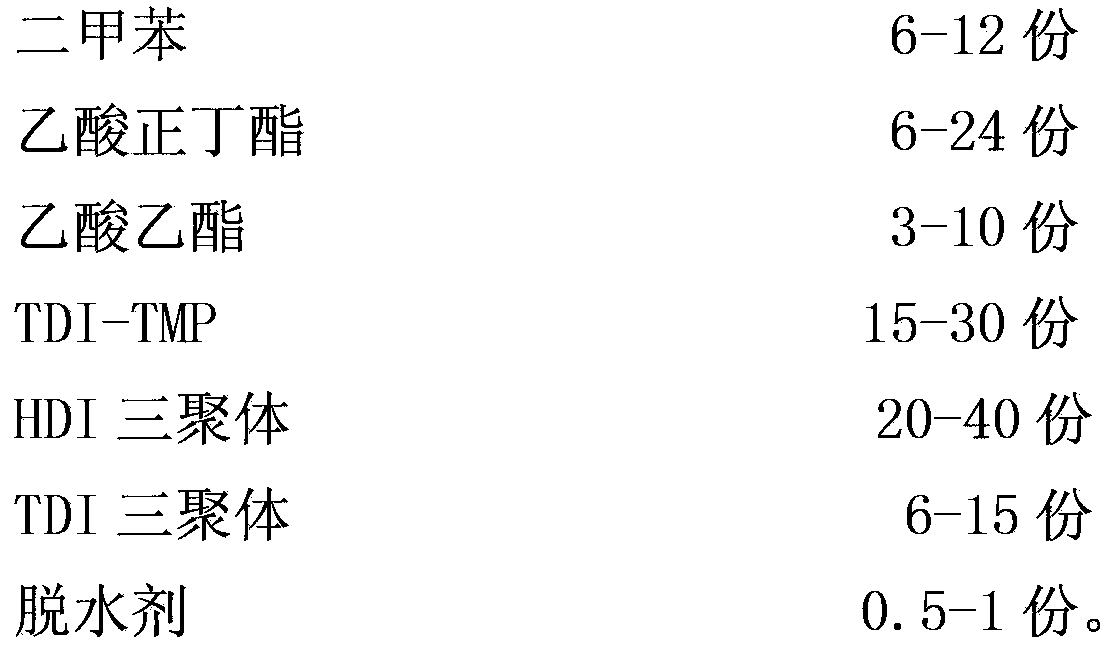

[0032] The ratio of NCO components and parts by weight is as follows:

[0033]

[0034] The above-mentioned preparation method of the matt polyurethane wood floor paint with the function of removing formaldehyde comprises the following steps:

[0035] (1), the hydroxyl component is prepared according to the following preparation method:

[0036] Alkyd resin, castor oil alkyd resin, dispersant, cyclohexanone, n-butyl acetate, ethyl acetate, xylene, defoamer, leveling agent, matting powder, bentonite, polyethylene wax powder, Add the polyami...

Embodiment 1

[0042] Embodiment 1: A matte polyurethane wood floor paint with formaldehyde removal function is prepared by mixing a hydroxyl component and an NCO component in a mass ratio of 1:0.8, wherein the hydroxyl component and the NCO component are respectively composed of the following components It is formulated with the ratio of parts by weight:

[0043] Wherein the hydroxyl components and parts by weight ratio are as follows:

[0044]

[0045] The ratio of NCO components and parts by weight is as follows:

[0046]

[0047]

[0048] A preparation method of a matt polyurethane wood floor paint with formaldehyde-removing function comprises the following steps:

[0049] (1), the hydroxyl component is prepared according to the following preparation method:

[0050] 60 parts of formaldehyde-removing alkyd resin, 10 parts of castor oil alkyd resin, 0.3 parts of dispersant, 4 parts of cyclohexanone, 8 parts of n-butyl acetate, 4 parts of ethyl acetate, 6 parts of xylene, 0.3 pa...

Embodiment 2

[0057] Example 2: A matt polyurethane wood floor paint with formaldehyde removal function is prepared by mixing a hydroxyl component and an NCO component in a mass ratio of 1:1, wherein the hydroxyl component and the NCO component are respectively composed of the following components It is formulated with the ratio of parts by weight:

[0058] Wherein the hydroxyl components and parts by weight ratio are as follows:

[0059]

[0060]

[0061] The ratio of NCO components and parts by weight is as follows:

[0062]

[0063] A preparation method of a matt polyurethane wood floor paint with formaldehyde-removing function comprises the following steps:

[0064] (1), the hydroxyl component is prepared according to the following preparation method:

[0065] 55 parts of formaldehyde removal alkyd resin, 15 parts of castor oil alkyd resin, 0.3 parts of dispersant, 4 parts of cyclohexanone, 7 parts of n-butyl acetate, 4 parts of ethyl acetate, 7 parts of xylene, 0.3 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com