Fluoroplastic-based micro-nano composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material and fluoroplastic technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of lack of shielding frequency bands and wave-absorbing performance characterization, and achieve excellent chemical corrosion resistance, scientific preparation methods, and excellent The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete steps of preparation are:

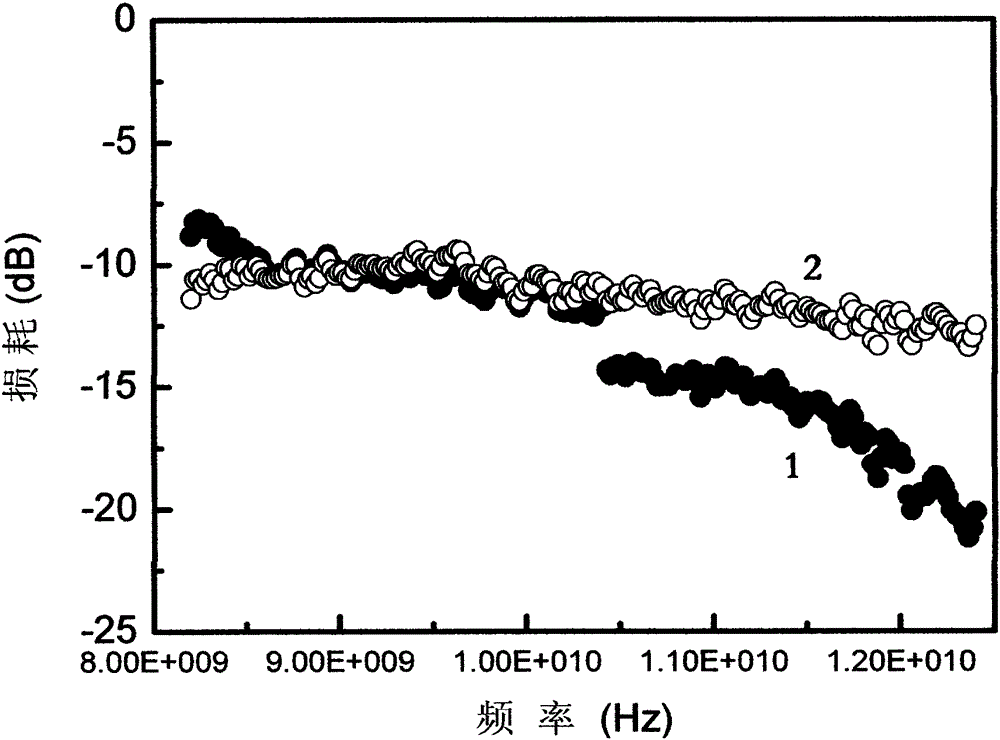

[0023] First, the fluoroplastic, carbon nanotube and basalt fiber are uniformly mixed according to the weight ratio of 100:0.5:20 to obtain a mixture; wherein, the fluoroplastic is polyvinylidene fluoride, and the carbon nanotube is single-wall carbon nanotube. The mixture was then placed in a torque rheometer and kneaded for 25 minutes at 200°C to obtain a mixture similar to figure 1 The fluoroplastic-based micro-nano composite absorbing material shown in curve 1.

Embodiment 2

[0025] The concrete steps of preparation are:

[0026] Firstly, the fluoroplastic, carbon nanotube and basalt fiber are uniformly mixed according to the weight ratio of 100:2:14 to obtain the mixture; wherein, the fluoroplastic is polyvinylidene fluoride, and the carbon nanotube is single-wall carbon nanotube. The mixture was then placed in a torque rheometer and kneaded at 240°C for 20 minutes to obtain figure 1 The fluoroplastic-based micro-nano composite absorbing material shown in curve 1.

Embodiment 3

[0028] The concrete steps of preparation are:

[0029] Firstly, the fluoroplastic, carbon nanotube and basalt fiber are uniformly mixed according to the weight ratio of 100:8:8 to obtain a mixture; wherein, the fluoroplastic is polyvinylidene fluoride, and the carbon nanotube is single-wall carbon nanotube. The mixture was then placed in a torque rheometer and kneaded for 15 minutes at 275°C to obtain a mixture similar to figure 1 The fluoroplastic-based micro-nano composite absorbing material shown in curve 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com