Automatic positioning and clamping device and method of drill rod and drill collar on pipe threading lathe

An automatic positioning and clamping device technology, applied in the field of metal cutting, can solve the problems of cumbersome procedures and low work efficiency, and achieve the effect of reducing dependence, reducing labor intensity and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

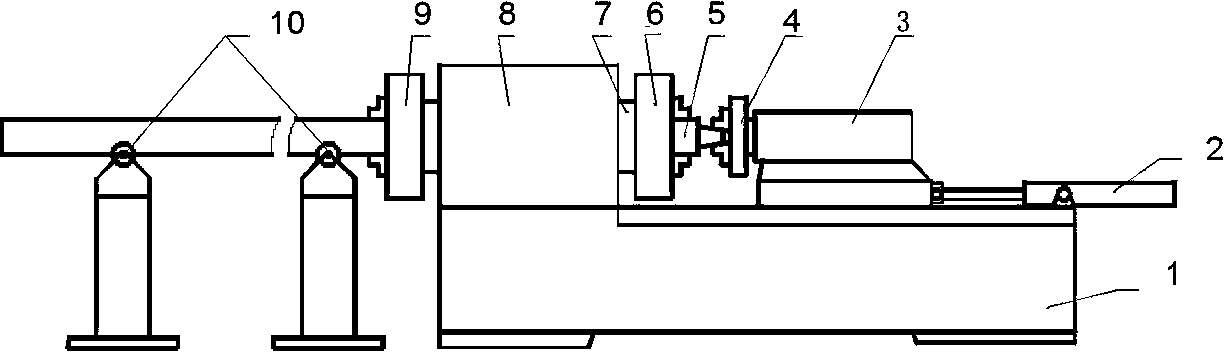

[0014] The specific embodiment: the invention will be further described below in conjunction with the accompanying drawings:

[0015] Such as figure 1 As shown, the invention provides an automatic positioning and clamping device for drill pipes and drill collars on a pipe thread lathe. Multiple sets of idler rollers 10 are arranged on one side of the bed, the bedside box 8 and the tail table 3 are arranged on the bed body, and the bedside box 8 is arranged on the side close to the multiple sets of idler rollers 10 of the bracket; the tail table 3 can be opposite Move back and forth on the bedside box 8; the main shaft 7 extending from the front and rear ends of the bedside box 8 is also provided in the bedside box 8, and the front floating chuck 6 and the rear centering chuck are respectively arranged on the front and rear ends of the main shaft 7. The chuck 9; the main shaft 7 is a hollow structure for the workpiece to pass through; the end of the tail table 3 facing the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com