Gearbox casing die-casting die

A gear case and die-casting mold technology, which is applied in the field of metal die-casting molds, can solve the problems of low casting quality, difficult production, and insufficient pressure transmission, and achieve high production efficiency, excellent casting quality, and avoid shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

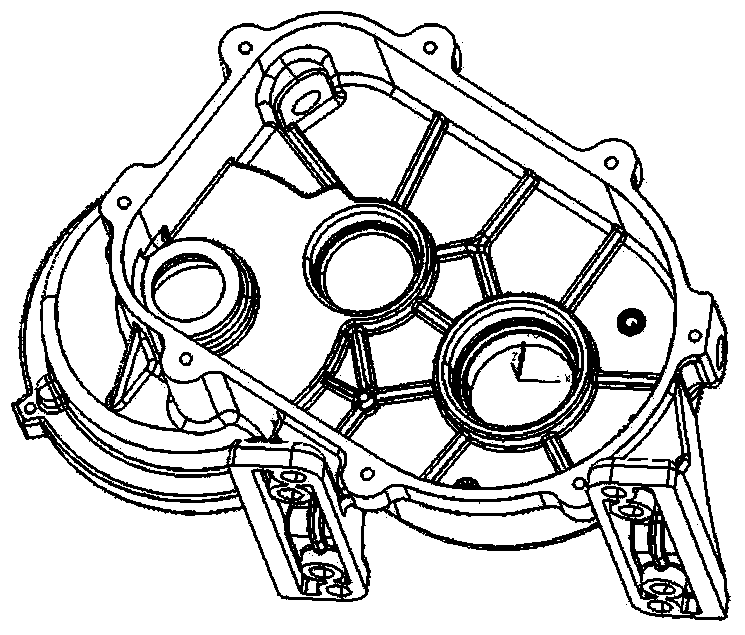

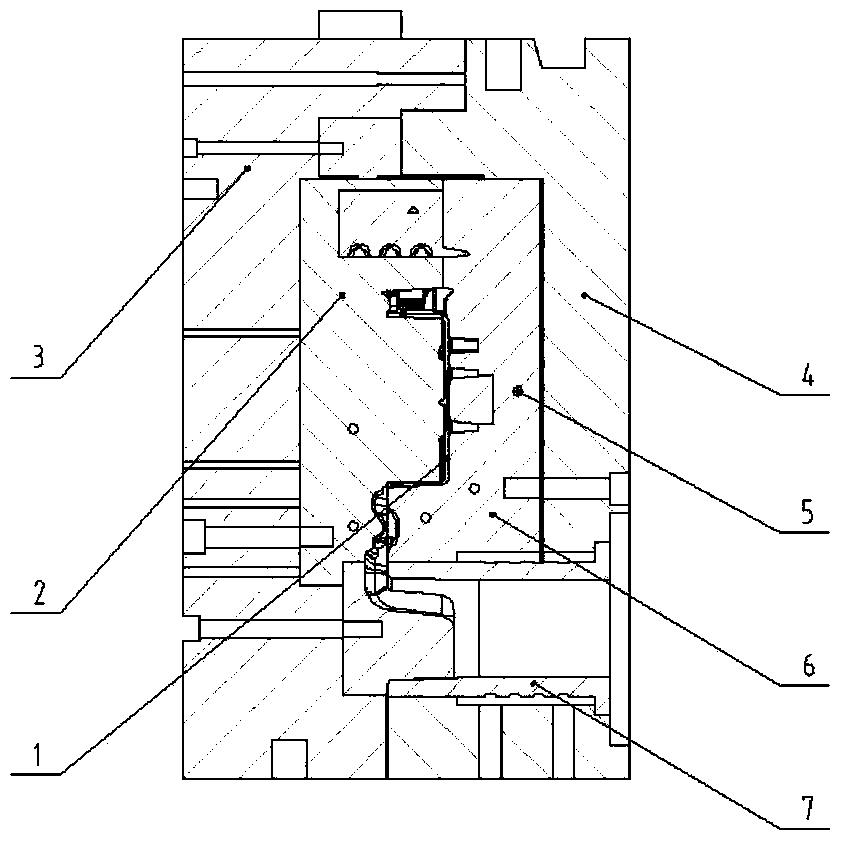

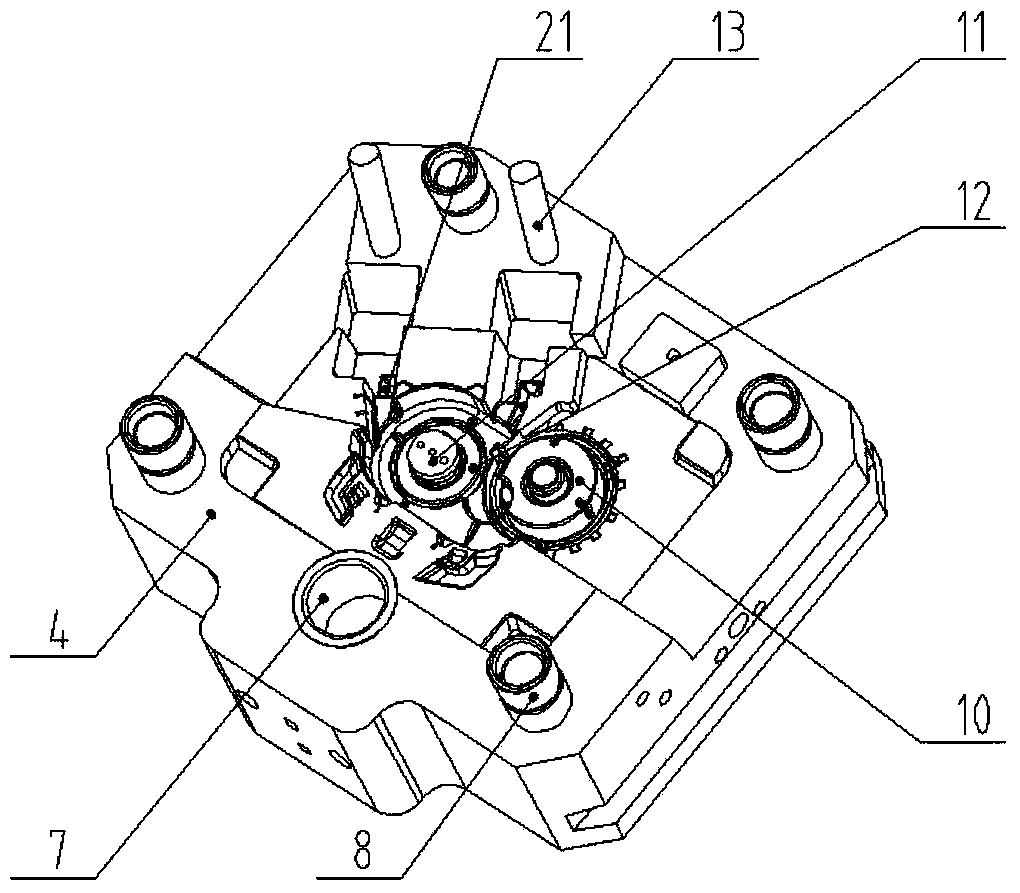

[0019] Depend on figure 2 Known, a kind of gear box body die-casting mold of the present invention comprises fixed mold frame 4, movable mold frame 3, fixed mold 6, movable mold 2, sprue sleeve 7, inclined guide post 9, fixed mold core-10, fixed mold Core two 11, fixed mold core three 12, movable mold additional block 17, guide post 13, guide sleeve 8, first slider 20, second slider 24, the three fixed mold cores are fixed together with fixed mold 6 , the two sliders are connected with the movable mold 2, and the action linkage is realized with the fixed mold 6 through the inclined guide column 9; the first slider 20, the second slider and the fixed mold 6, the movable mold 2, A fixed mold core 10, a fixed mold core 2 11, a fixed mold core 3 12, and a movable mold insert 19 form a gear box body cavity 1. The pouring system of the mold consists of a runner 15 and an inner runner 14 on the fixed mold. The runner 15 is divided into five at the mold gate, and the mold overflow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com