Rotating disc type runoff lightning shield dust remover

A technology of rotary disc and dust collector, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc. It can solve the problems of unable to meet the requirements of dust removal, reduced air flow of electrostatic precipitator, and difficulty in meeting processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

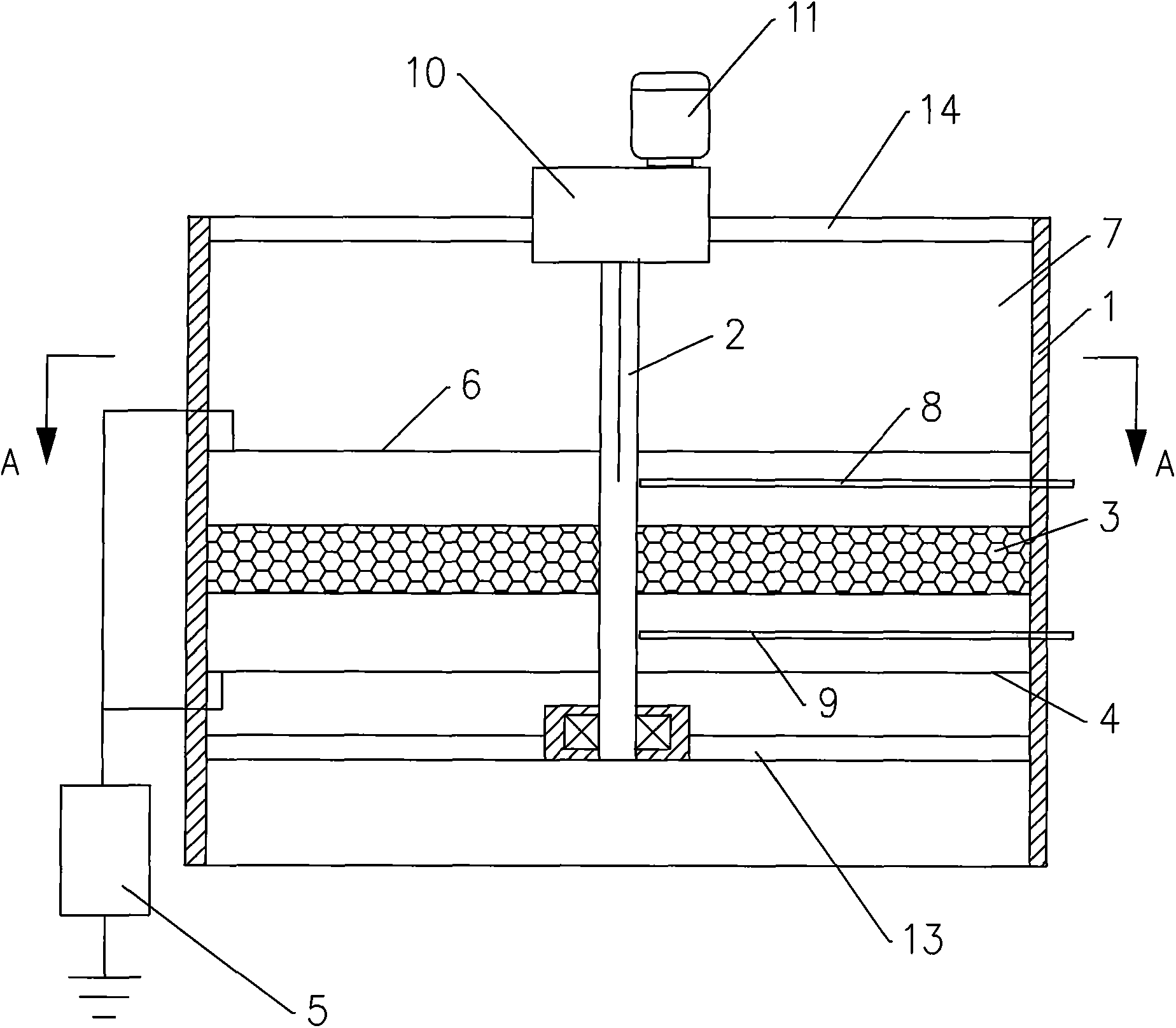

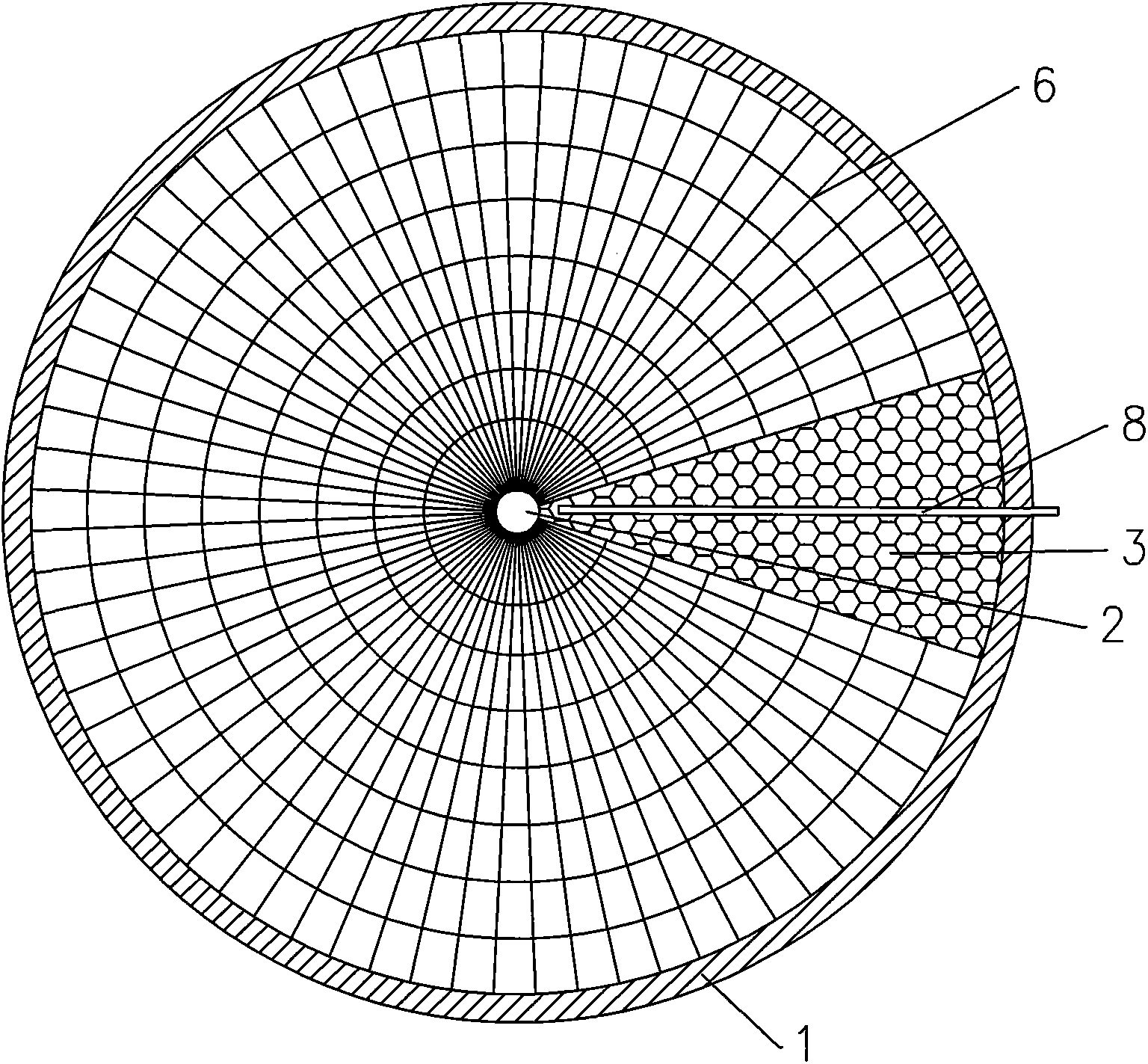

[0019] Such as figure 1 with figure 2 As shown, the rotary disc type radial flow electric shield dust collector of the present invention includes a casing 1, and a dust gas pipeline 7 is arranged in the casing 1, and a disc-shaped electric shield 3 that allows air flow to pass through is provided in the dust gas pipeline 7. , the disk surface of the electric shield 3 can rotate around the cross-section of the dust and gas pipeline 7, the circumferential surface of the electric shield 3 and the inner wall of the dust and gas pipeline 7 are clearance fits, and the electric shield 3 is provided with a front discharge device facing the front of the dust and gas pipeline 7 inlet direction. The net 4, the end face of the electric shield 3 facing the front discharge net 4 is parallel to the front discharge net 4, and the electric shield 3 is made of porous foam metal or a plurality of parallel corrugated plates or a plurality of parallel flat plates or honeycomb plates or wire mesh,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com