Method for operating a gas sensor element and device for carrying out said method

A sensor element, gas technology, applied in the structural details of gas analyzers, testing of machine/structural components, diagnostic devices of exhaust gas treatment devices, etc., can solve problems such as damage, wrong heating voltage, sensor element distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

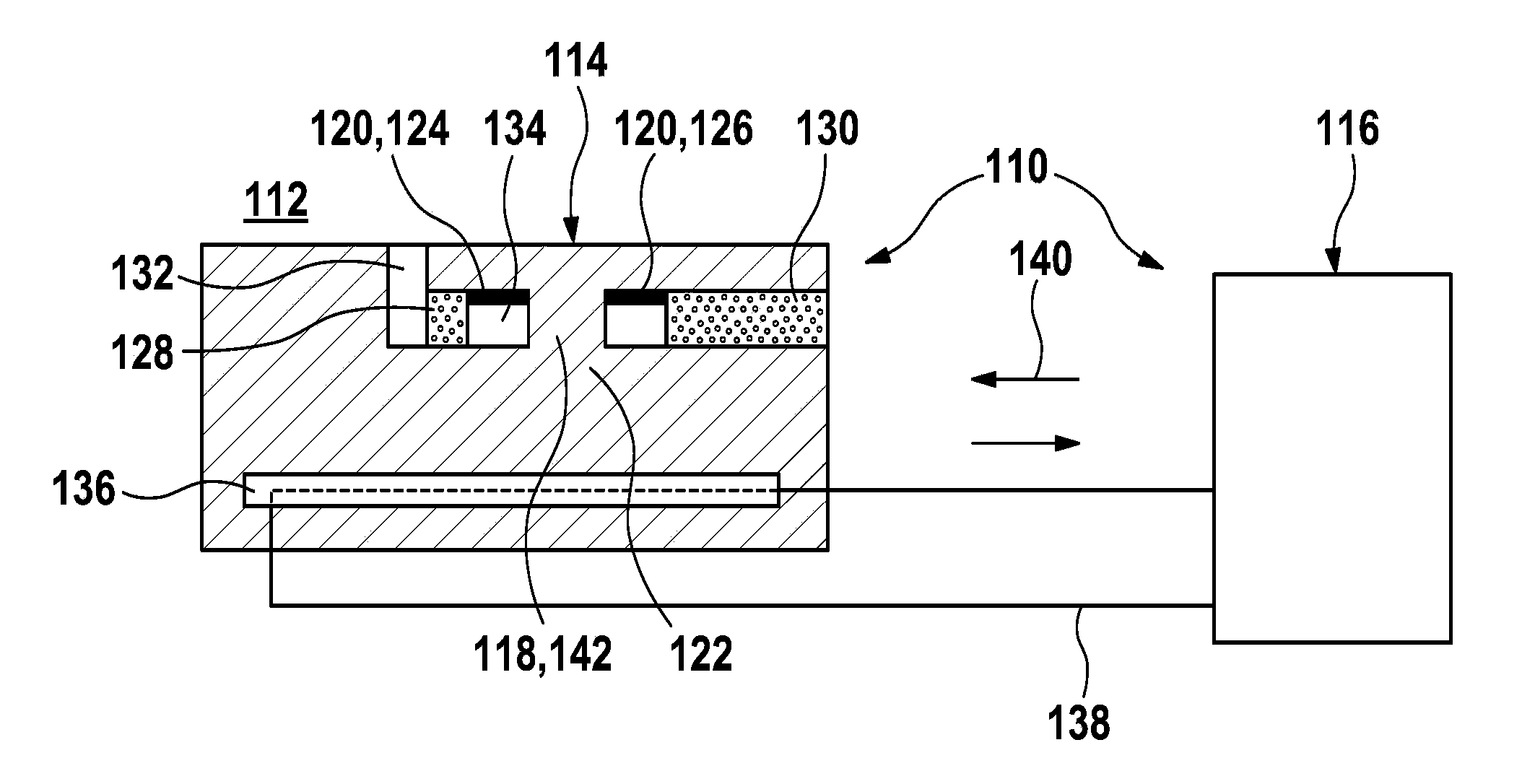

[0041] exist figure 1An embodiment of a device 110 according to the invention is shown in . The device 110 according to the invention for detecting at least one property of a gas in a measurement gas chamber 112 includes at least one sensor element 114 . Device 110 also has at least one controller 116 . Controller 116 is provided to carry out the method according to the invention for operating at least one sensor element 114 for detecting at least one property of the gas in measurement gas chamber 112 . In particular, sensor element 114 may be designed as a lambda probe. The sensor element 114 can be designed, for example, as a one-unit or multi-unit sensor element 114 . A cell 118 can be understood here as an arrangement of at least two electrodes 120 and a solid electrolyte 122 , for example. The solid electrolyte 122 may in particular be a ceramic solid electrolyte 122 , for example zirconium dioxide, in particular yttrium-stabilized zirconia (YSZ) and / or scandium-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com