Digital phase locking and frequency tracking electromagnetic induction heating power controller

An electromagnetic induction heating and power controller technology, applied in the direction of induction heating control, induction heating, irreversible DC power input conversion to AC power output, etc., can solve the problem of limited precision, complex signal processing process, digital low-pass filter Problems such as difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

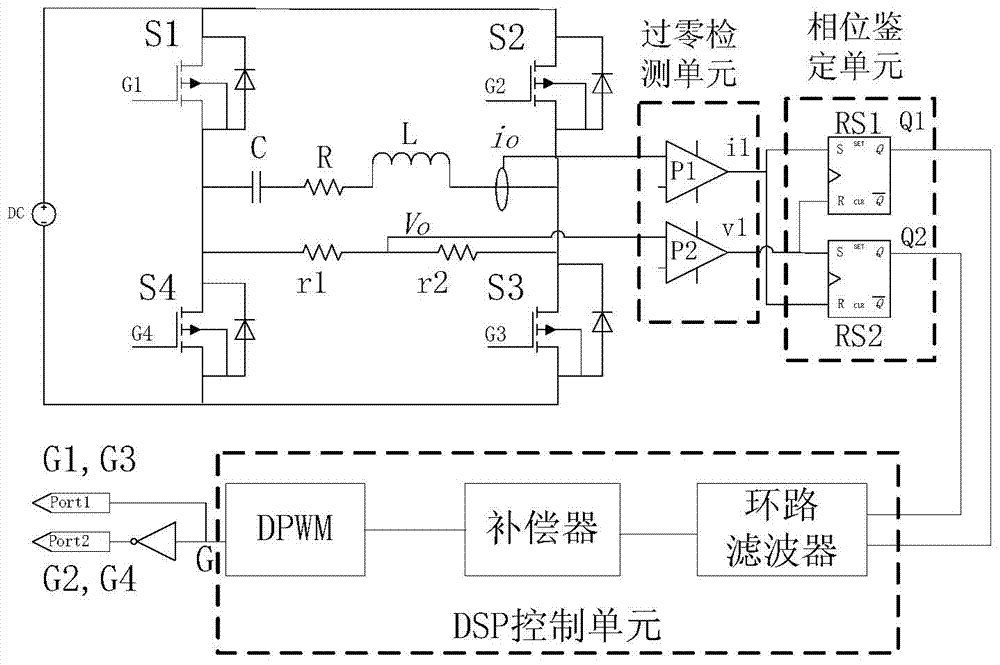

[0015] Electromagnetic induction heating power supply controller with digital phase-locking and frequency tracking, such as figure 1 As shown, it includes a zero-crossing detection unit, a phase identification unit and a DSP control unit; the zero-crossing detection unit includes two parallel zero-crossing detection circuits, wherein the first zero-crossing detection circuit P1 is used for the electromagnetic induction heating power supply The sampling signal i of the output current of the full-bridge inverter o Perform zero-crossing detection and output the sampling signal i o The zero-crossing detection digital output signal i1 of the second zero-crossing detection circuit P2 samples the output voltage V of the full-bridge inverter in the electromagnetic induction heating power supply o Perform zero-crossing detection and output sampling signal V oThe zero-crossing detection digital output signal v1; the phase identification unit includes two RS flip-flops RS1 and RS2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com