A bionic inchworm-type piezoelectric rotary driver

A technology of rotary drive and bionic ruler, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., which can solve the problems of insufficient processing accuracy, wear, and affecting the accuracy of the drive. , to achieve the effect of large load power output and precise driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

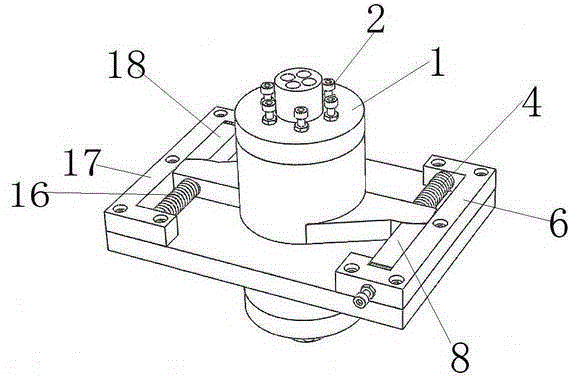

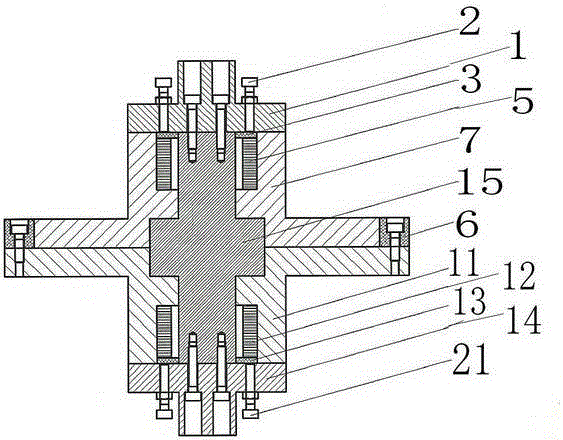

[0020] see Figure 1 to Figure 4 As shown, this embodiment is composed of the first output shaft 1, the first clamping pre-tightening bolt 2, the first clamping pre-tightening ring 3, the first return spring 4, the first annular clamping piezoelectric stack 5, the first A driving piezoelectric stack frame 6, a driving arm 7, a first driving piezoelectric stack 8, a first driving pretension block 9, a first driving pretension bolt 10, a base 11, and a second annular clamping piezoelectric stack 12. The second clamp pretension ring 13, the second output shaft 14, the drive shaft 15, the second return spring 16, the second drive piezoelectric stack frame 17, the second drive piezoelectric stack 18, the second drive preload Tightening block 19, the second driving pre-tightening bolt 20, the second clamping pre-tightening bolt 21 is composed;

[0021] The first output shaft 1 and the second output shaft 14 are respectively connected to the two ends of the drive shaft 15 by bolts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com