Novel asphalt concrete pavement structure

A technology of asphalt concrete and pavement structure, which is applied to the cohesive pavement paved on site, roads, roads, etc., to achieve the effects of preventing rainwater erosion, high resistance to deformation and durability, and preventing landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

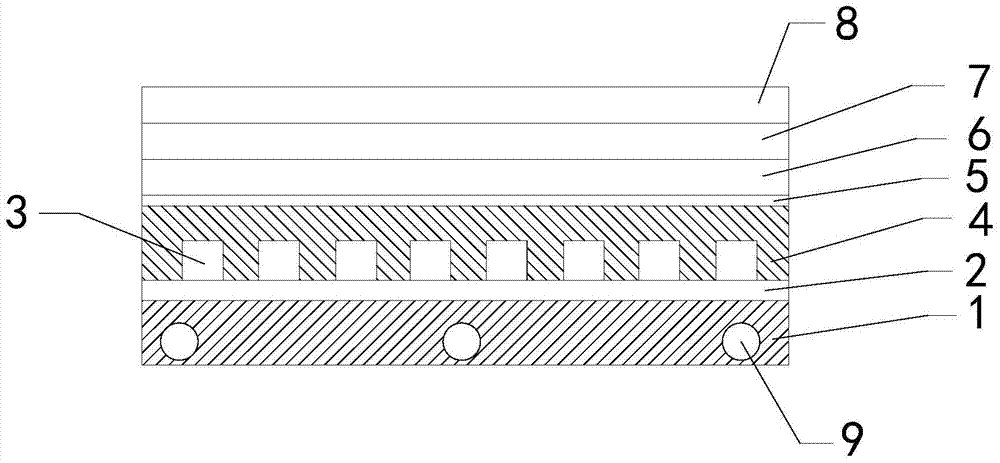

[0010] Such as figure 1 As shown, the novel asphalt concrete pavement structure of the present invention comprises a base layer 1, a mortar adhesion layer 2, a cement concrete prefabricated block 3, a crushed stone layer 4, a slurry seal layer 5, a coarse-grained asphalt concrete layer 6, and a medium-grained asphalt The concrete layer 7 and the asphalt mastic macadam mixture layer 8 are covered with a mortar adhesion layer above the base layer, and cement concrete prefabricated blocks parallel to each other and arranged at intervals are arranged above the mortar adhesion layer. The long sides of the cement concrete prefabricated blocks are The extension direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com