Strong glue

A glue and strong technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of not being able to bond different materials, high free formaldehyde content, slow bonding speed, etc., and achieve fast bonding and excellent production process Simple, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

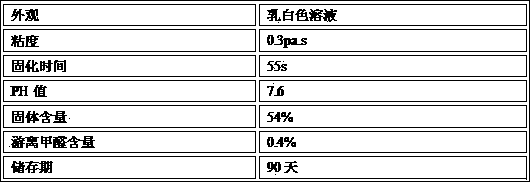

Embodiment 1

[0015] A kind of superglue described in this embodiment is mainly composed of the following raw materials in parts by weight:

[0016] Formaldehyde: 35 parts, urea: 18 parts, polyvinyl alcohol: 4 parts, distilled water: 50 parts, formaldehyde scavenger: 22 parts, sodium hydroxide: 2 parts, hydrochloric acid 1 part, antifungal agent 0.5 parts.

[0017] A kind of superglue described in the present embodiment, concrete preparation method, comprises the following steps:

[0018] 1. Add the formaldehyde scavenger to the reaction kettle, add the same weight of water and stir for 3 minutes;

[0019] 2. Add 34% formaldehyde, polyvinyl alcohol and water to the reaction kettle, stir for 4 minutes, during the stirring process, add urea in 3 times;

[0020] 3. Heat the solution in the reactor to 96°C, stop heating, and react for 160 minutes;

[0021] 4. Cool down to 72°C, add hydrochloric acid to make the pH value of the solution reach 4.5-5, and let it stand for 3 minutes;

[0022] 5....

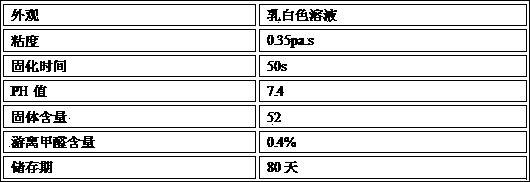

Embodiment 2

[0037] A kind of superglue described in this embodiment is mainly composed of the following raw materials in parts by weight:

[0038] 42 parts of formaldehyde, 23 parts of urea, 4 parts of polyvinyl alcohol, 55 parts of distilled water, 24 parts of formaldehyde scavenger, 3 parts of sodium hydroxide, 2 parts of hydrochloric acid, 0.5 parts of antifungal agent.

[0039] A kind of super glue described in this embodiment, the specific preparation method comprises the following steps.

[0040] 1. Add the formaldehyde scavenger to the reaction kettle, add the same weight of water and stir for 4 minutes;

[0041] 2. Add 35% formaldehyde, polyvinyl alcohol and water to the reaction kettle, stir for 5 minutes, during the stirring process, add urea in 4 times;

[0042] 3. Heat the solution in the reactor to 80-100°C, stop heating, and react for 170 minutes;

[0043] 4. Cool down to 73°C, add hydrochloric acid to make the pH of the solution reach 4.8, and let it stand for 2 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com