Expandable polystyrene particle coating agent and preparation method and application thereof

A technology of expandable polystyrene and coating agent, which is applied in the direction of coating, etc., can solve the problems of poor fluidity, reduced foaming ratio, and less adsorption, so as to achieve good fluidity, improve molding efficiency, and reduce hair loss. Effect of Foaming Agent and Auxiliary Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

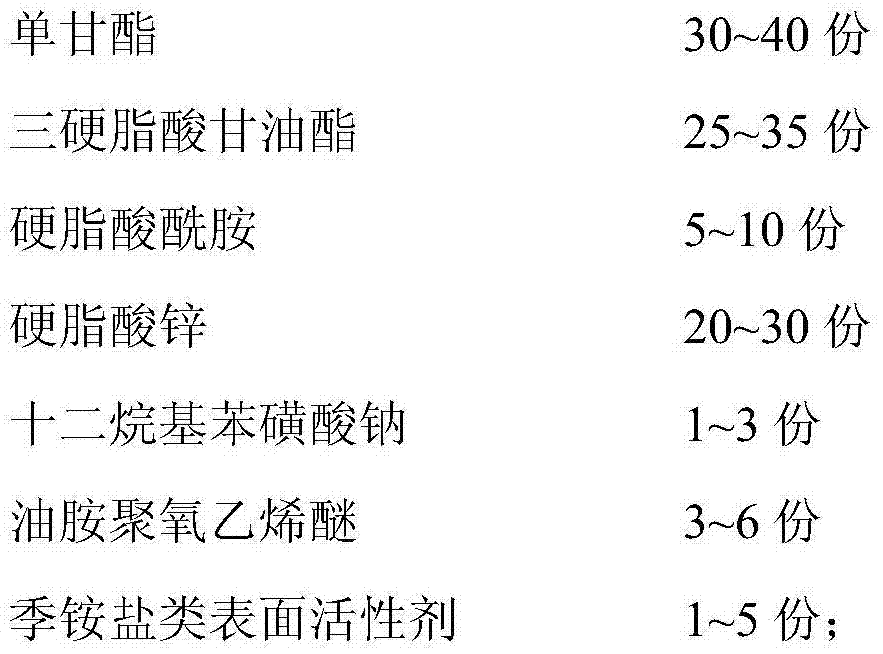

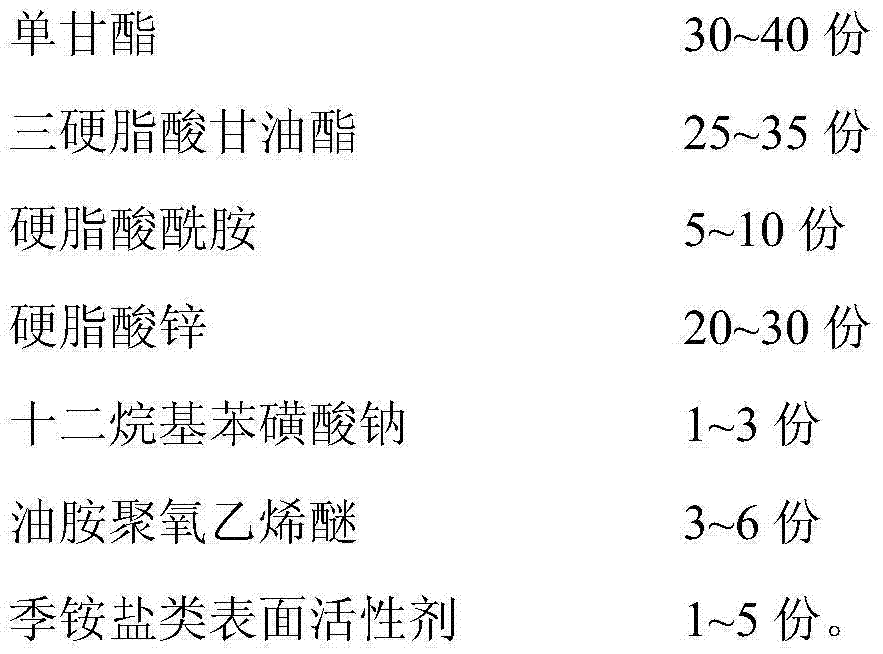

Method used

Image

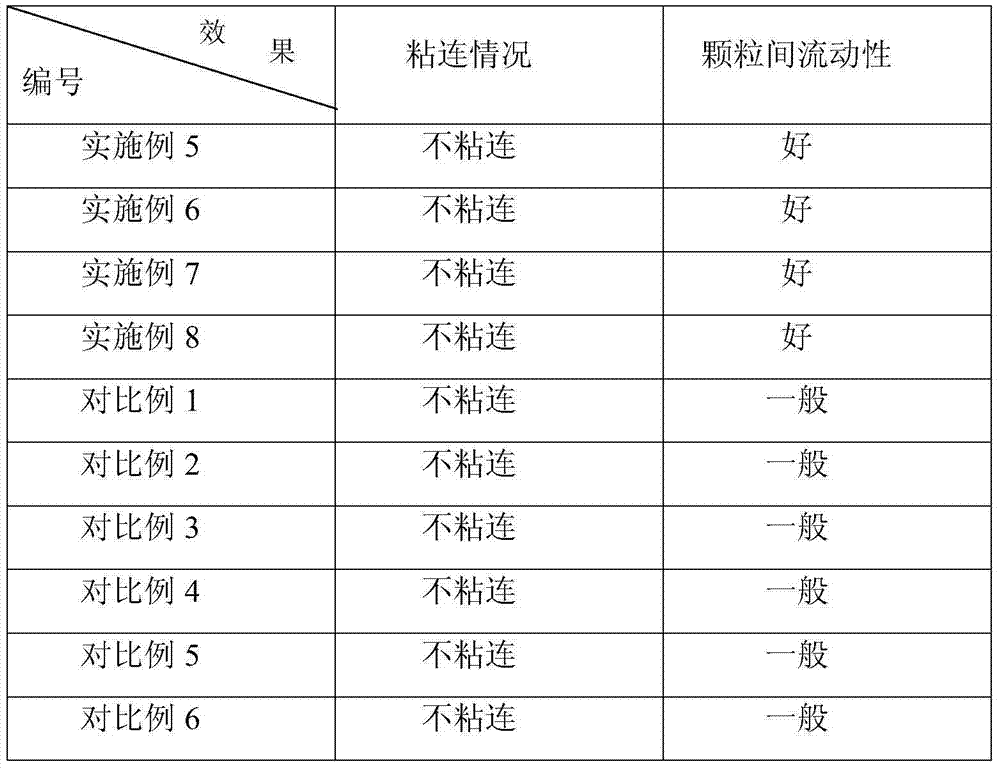

Examples

Embodiment 1

[0031] Grind 35g of monoglyceride, 30g of glyceryl tristearate, 25g of zinc stearate, and 6g of stearic acid amide. The fineness requires a 200-mesh standard sieve with a passing capacity of ≥95%. Take the sieved material of the four raw materials , and then mixed and stirred to obtain coating agent T1;

[0032] When coating EPS raw particles, first add 20kg of EPS raw particles into the mixer, then add 40g of coating agent T1 and mix for 30 minutes.

Embodiment 2

[0034] Grind 30g of monoglyceride, 35g of glyceryl tristearate, 30g of zinc stearate, and 10g of stearic acid amide. The fineness requires a 200-mesh standard sieve with a passing capacity of ≥95%. Take the sieved material of the four raw materials , and then mixed and stirred to obtain coating agent T2;

[0035] When coating EPS raw particles, first add 20kg of EPS raw particles into the mixer, then add 50g of coating agent T2 and mix for 30 minutes.

Embodiment 3

[0037] Grind 40g of monoglyceride, 30g of glyceryl tristearate, 20g of zinc stearate, and 10g of stearic acid amide. The fineness requires a 200-mesh standard sieve with a passing capacity of ≥95%. Take the sieved material of the four raw materials , and then mixed and stirred to obtain coating agent T3;

[0038] When coating EPS raw particles, first add 20kg of EPS raw particles into the mixer, then add 60g of coating agent T3 and mix for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com