Preparation method of cloxacillin molecular imprinting polymer membrane

A technology of cloxacillin and molecular imprinting, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that the preparation of cloxacillin molecularly imprinted membranes has not been reported yet, and achieve easy handling and application, low testing cost, and high long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the cloxacillin molecularly imprinted polymer membrane of the present invention comprises the following steps:

[0027] (1) Preparation of Cloxacillin Polymer Solution

[0028] Weigh cloxacillin and dissolve it in the porogen, ultrasonically, until the cloxacillin is completely dissolved to obtain 20-100 mg / ml cloxacillin organic solution;

[0029] In the above-mentioned cloxacillin organic solution, add the functional monomer, wherein the molar ratio of the template molecule (cloxacillin) to the functional monomer is 1:2-1:12; then vortex for 5-20min to make the cloxacillin Sufficient pre-polymerization of penicillin and functional monomers; then add cross-linking agent (the degree of cross-linking is 60-90%) and initiator (the ratio of initiator to functional monomer is 1:10-1:20) in the solution After being mixed uniformly, the required cloxacillin polymerization solution is obtained; the porogen is dimethylacetamide DMAC, N-methylpyrrolido...

Embodiment 1

[0034] (1), preparation of cloxacillin polymer solution:

[0035] Weigh 170mg of cloxacillin into 7ml of DMF, ultrasonically dissolve at 60°C, then add 0.25μl MAA and vortex for 20min to fully pre-polymerize cloxacillin and functional monomers, then add 1.5ml of EDMA, 66mg of TPO and vortex Make it evenly mixed, and then pass nitrogen gas for 10 minutes to remove oxygen to obtain cloxacillin polymerization solution.

[0036] (2) Preparation of cloxacillin molecularly imprinted polymer membrane:

[0037] Immerse the commercialized PVDF in the above polymerization solution, continue to pass nitrogen gas in the solution for 10 minutes to remove oxygen, and then seal it; after standing for 20 minutes, transfer the soaked PVDF to a closed container that has been deoxygenated; The reaction was irradiated for 4 hours; then step (2) was repeated three times.

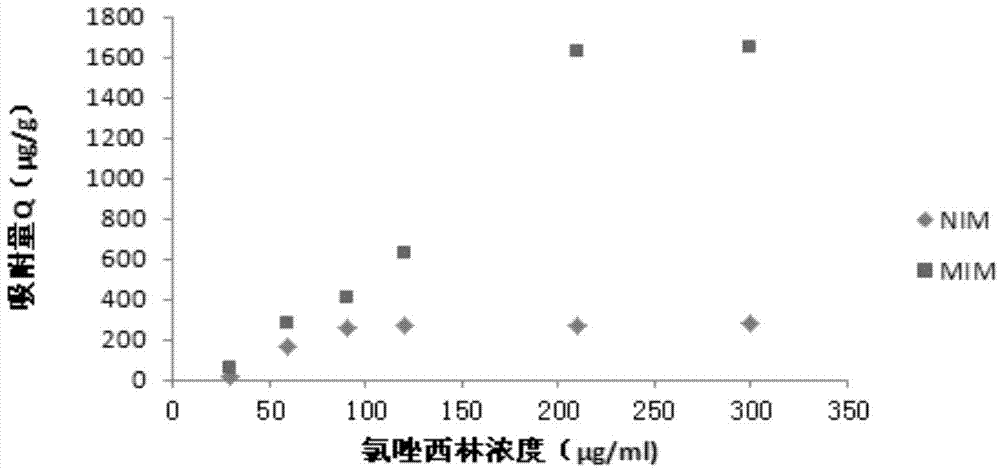

[0038] The membrane obtained from the above polymerization was eluted with a mixture of methanol and glacial acetic acid (me...

Embodiment 2

[0041] (1), preparation of cloxacillin pre-polymerization solution:

[0042] Weigh 170.4mg cloxacillin into 7.5ml DMSO, dissolve it by ultrasonic at 50℃, then add 0.35ml MAA and vortex for 10min to fully pre-polymerize cloxacillin and functional monomer, then add 1.8ml TRIM, 100mg AIBN and vortex Rotate to mix well, and then pass nitrogen gas for 5 minutes to remove oxygen to obtain cloxacillin polymer solution.

[0043] (2) Preparation of cloxacillin molecularly imprinted polymer membrane:

[0044] Immerse the commercialized PVDF membrane in the above-mentioned cloxacillin polymerization solution, continue to pass nitrogen in the solution for 5 minutes to remove oxygen, and then seal it; Irradiate and react under the cross-linking instrument for 12 hours; then repeat step (2) once more.

[0045] The membrane obtained from the above polymerization was eluted with a mixture of methanol and acetic acid (methanol / glacial acetic acid = 1 / 1, v / v) under Soxhlet reflux until no tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com