Short-flow recycling process of drum-method circulating water sludge

A drum method and circulating water technology, applied in the field of metallurgy, can solve problems such as affecting drum production, restricting the continuous production capacity of drums, affecting the normal operation of the circulating water system, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

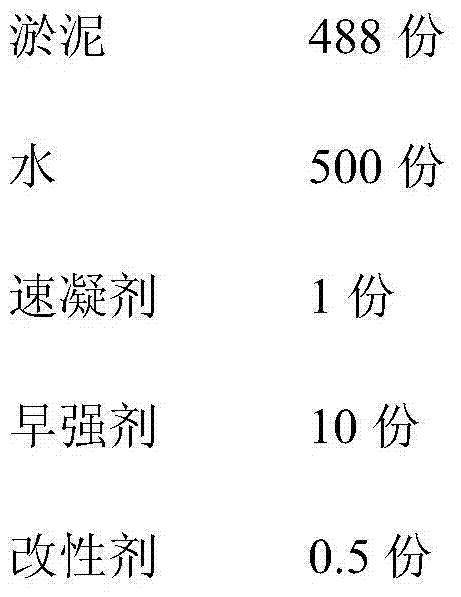

[0036] The components of each part by weight in the slurry of the gunning slag tank are as follows:

[0037]

[0038]

[0039] Wherein: in embodiment 1, the residue after the sieve of 40 μm is crossed by mud is 2wt%;

[0040] The water is middle water;

[0041] The accelerator is TK-782;

[0042] The early strength agent is calcium sulfate hemihydrate;

[0043] The modifier is microsilica;

[0044] The pumping agent is bentonite.

[0045] Microsilica fume is microsilica fume produced by Shanghai Tiankai Silicon Fume Material Co., Ltd.;

[0046] The accelerator is a high-efficiency accelerator produced by Shanghai Tiankai Silicon Powder Material Co., Ltd.;

[0047] The slurry of the gunning slag tank in embodiment 1 is gunned according to the gunning method in the present invention; specifically:

[0048] 1) First pour the sludge into the spray tank for stirring;

[0049] 2) Put the flocculant, early strength agent, modifier and pumping agent in the above parts by ...

Embodiment 2

[0052] The components of each part by weight in the slurry of the gunning slag tank are as follows:

[0053]

[0054] In embodiment 2, the residue after the sieve of 40 μm is crossed by sludge is 5wt%;

[0055] The water is middle water;

[0056] The accelerator is TK-782;

[0057] The early strength agent is calcium sulfate hemihydrate;

[0058] The modifier is microsilica;

[0059] The pumping agent is bentonite.

[0060] Microsilica fume is microsilica fume produced by Shanghai Tiankai Silicon Fume Material Co., Ltd.;

[0061] The accelerator is a high-efficiency accelerator produced by Shanghai Tiankai Silicon Powder Material Co., Ltd.;

[0062] The slurry of the gunning slag tank in embodiment 2 is gunned according to the gunning method in the present invention; specifically:

[0063] 1) First pour the sludge into the spray tank for stirring;

[0064] 2) Put the flocculant, early strength agent, modifier and pumping agent in the above parts by weight into the sp...

Embodiment 3

[0067] The components of each part by weight in the slurry of the gunning slag tank are as follows:

[0068]

[0069] In embodiment 3, the residue after the sieve of 40 μm is crossed by sludge is 0wt%;

[0070] The water is middle water;

[0071] The accelerator is TK-782;

[0072] The early strength agent is calcium sulfate hemihydrate;

[0073] The modifier is microsilica;

[0074] The pumping agent is bentonite.

[0075] Microsilica fume is microsilica fume produced by Shanghai Tiankai Silicon Fume Material Co., Ltd.;

[0076]The accelerator is a high-efficiency accelerator produced by Shanghai Tiankai Silicon Powder Material Co., Ltd.;

[0077] The slurry of the gunning slag tank in embodiment 3 is gunned according to the gunning method in the present invention; specifically:

[0078] 1) First pour the sludge into the spray tank for stirring;

[0079] 2) Put the flocculant, early strength agent, modifier and pumping agent in the above parts by weight into the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com