Micro-disturbance-torque environment simulation device suitable for spacecraft simulated test

An environmental simulation device and a technology of micro-interference torque, applied in the field of measurement, can solve the problem of no specific design method of the air-floating table, and achieve the effects of small temperature change, simple design principle, and small friction force/torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

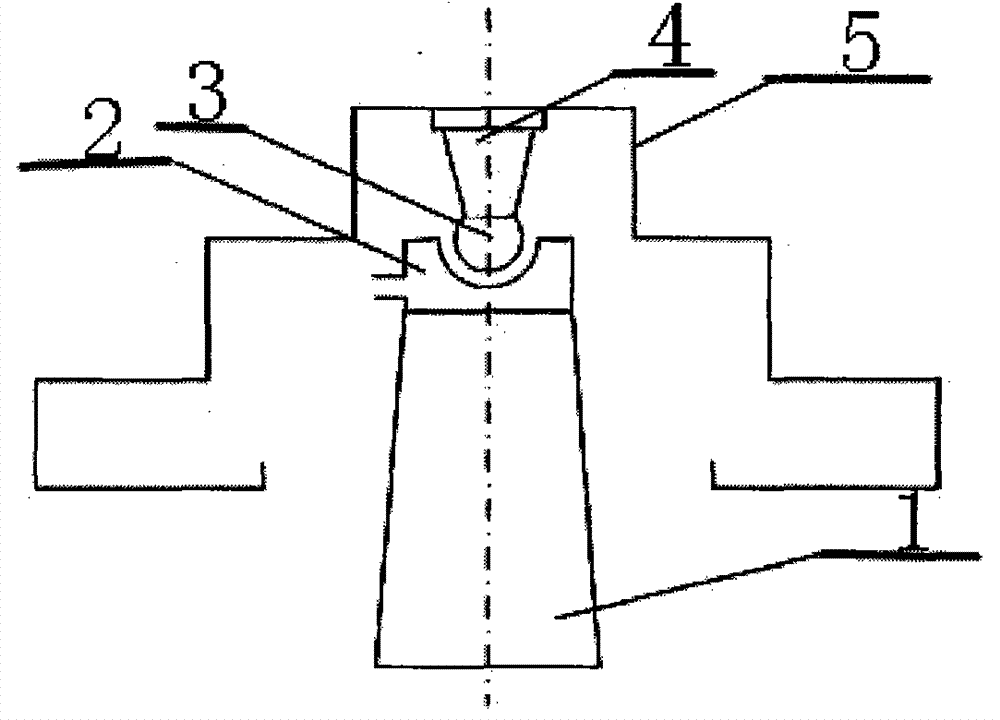

[0017] combine figure 1 , a micro-disturbance moment environment simulation device suitable for space vehicle simulation tests, comprising a base 1, an air-floating ball bearing pair, an adapter ring 4 and an instrument platform 5, and the air-floating ball bearing pair includes an air-floating ball shaft 3. Public buffer chamber 6, single row of annular space orifice 7, exhaust hole 8, annular space restrictor 9 and air-floating ball bearing 2, base 1 is installed on the foundation, and the lower end of air-floating ball bearing 2 is installed on the foundation On the seat 1, the air-floating ball shaft 3 can be suspended on the air-floating ball bearing 2, the air-floating ball shaft 3 can rotate freely in three dimensions, the upper end of the air-floating ball shaft 3 is provided with an adapter ring 4, and the adapter ring 4 is connected to the instrument platform 5 fixed connection, can be installed with different specifications of the instrument platform; the air float ...

Embodiment 2

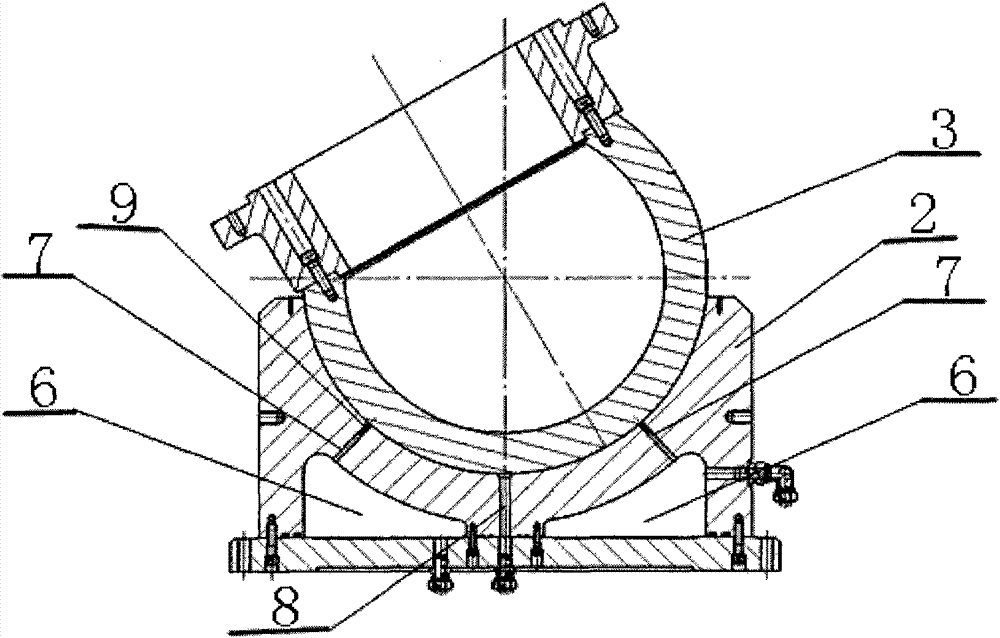

[0019] Such as figure 2 As shown, the air-floating ball bearing pair includes an air-floating ball shaft 3, a common buffer chamber 6, a single row of annular space orifices 7, an exhaust hole 8, an annular space restrictor 9 and an air-floating ball bearing 2, wherein The air-floating ball shaft 3 adopts a hollow design, which reduces its own weight and improves the effective load capacity while ensuring its own rigidity; the air-floating ball bearing 2 is designed with a single row of annular gap orifices 7, and the bottom of the air-floating ball bearing 2 is designed with one The air vent 8 improves the manufacturing process, avoids the turbulence problem of multi-row throttle holes and air vents, and improves the performance of the system; the air-floating ball bearing 2 is designed with a public buffer chamber 6. On the one hand, it can Play the role of filtering and stabilizing the air supply pressure, play a "damping" effect on the air bearing 2, and further improve t...

Embodiment 3

[0021] Such as figure 2 As shown, the annular gap restrictor 9 is embedded in the air bearing ball bearing, and an interference fit is selected to prevent air leakage on the mating surface or the restrictor falls off under pressure, hindering the normal operation of the air bearing pair . Since the restrictor is a separate part, it is not only convenient for processing and maintenance, but also ensures the same precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com