Railway freight car bogie

A technology for railway wagons and bogies, which is applied in the direction of bogies, railway car body parts, railway braking systems, etc., and can solve the problems of vehicle braking or mitigation performance adverse effects, inconvenient maintenance and repair, high manufacturing costs, etc., to improve manufacturing The effects of dynamic relief, easy maintenance and repair, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

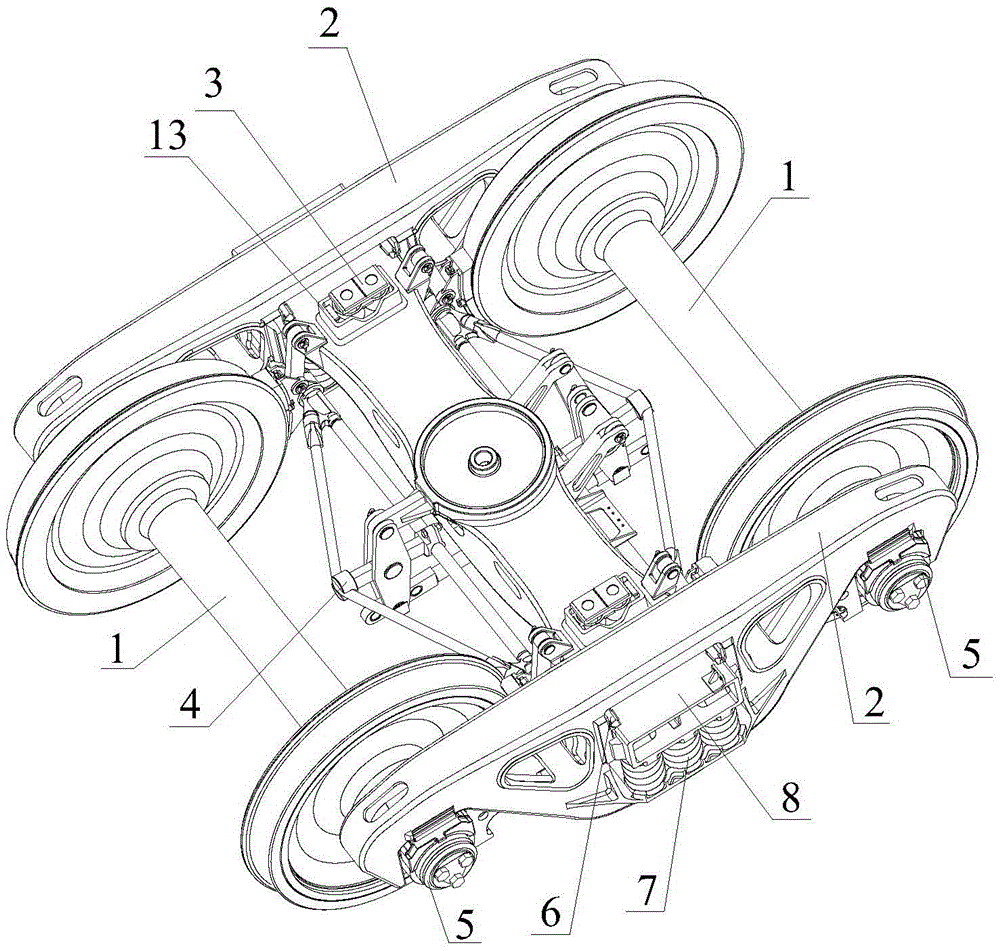

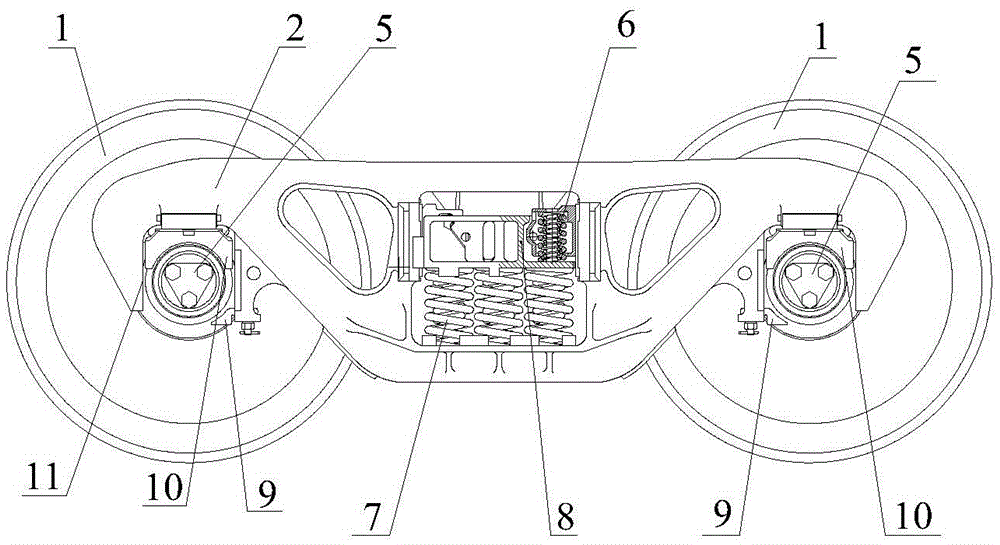

[0051] Such as figure 1 , 2 The railway freight car bogies shown in, 3 and 4 include front and rear wheel sets consisting of 1, two side frames 2, two lower side bearings, 3, suspension type basic braking device 4, four rolling bearing devices 5, four A wedge damping device 6, two sets of central load-bearing springs 7, a bolster 8, four stop keys 9, four load-bearing saddles 10, etc.

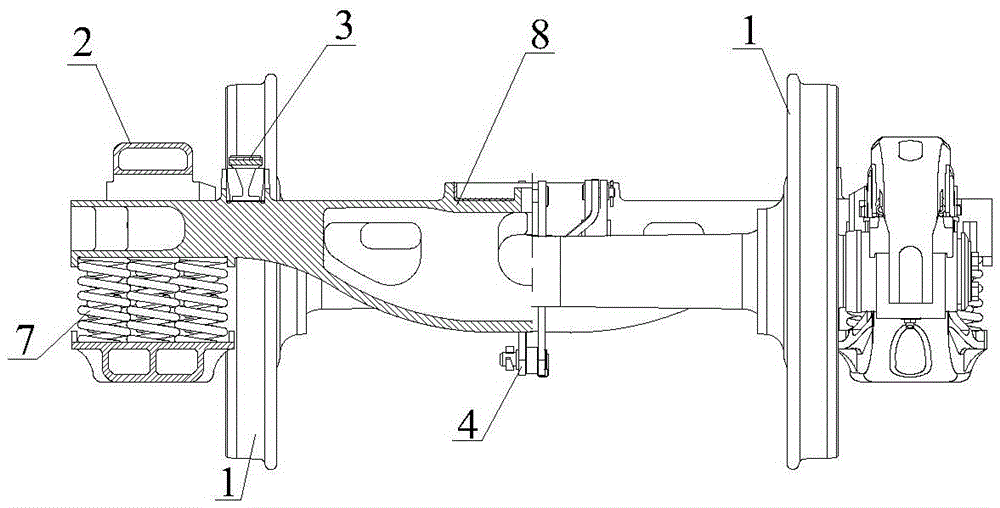

[0052] Combine Figure 5 , 6 , Wherein the rolling bearing device 5 is installed at both ends of the wheelset component 1, the pedestal frame 11 at both ends of the side frame component 2 is placed on the rolling bearing device 5 through the saddle 10; the top surface of the pedestal frame 11 of the side frame component 2 is embedded The pedestal wear plate 11.1, the pedestal wear plate 11.1 has an open structure, the top size of the open structure is larger than the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com