Servo power cutter head

A milling head and power technology, which is applied in the direction of driving devices, automatic lathes/semi-automatic lathes, turning equipment, etc., can solve problems such as difficult conversion, difficult conversion links, cumbersome procedures, etc., to achieve extended service life, stable operation, and reduced noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

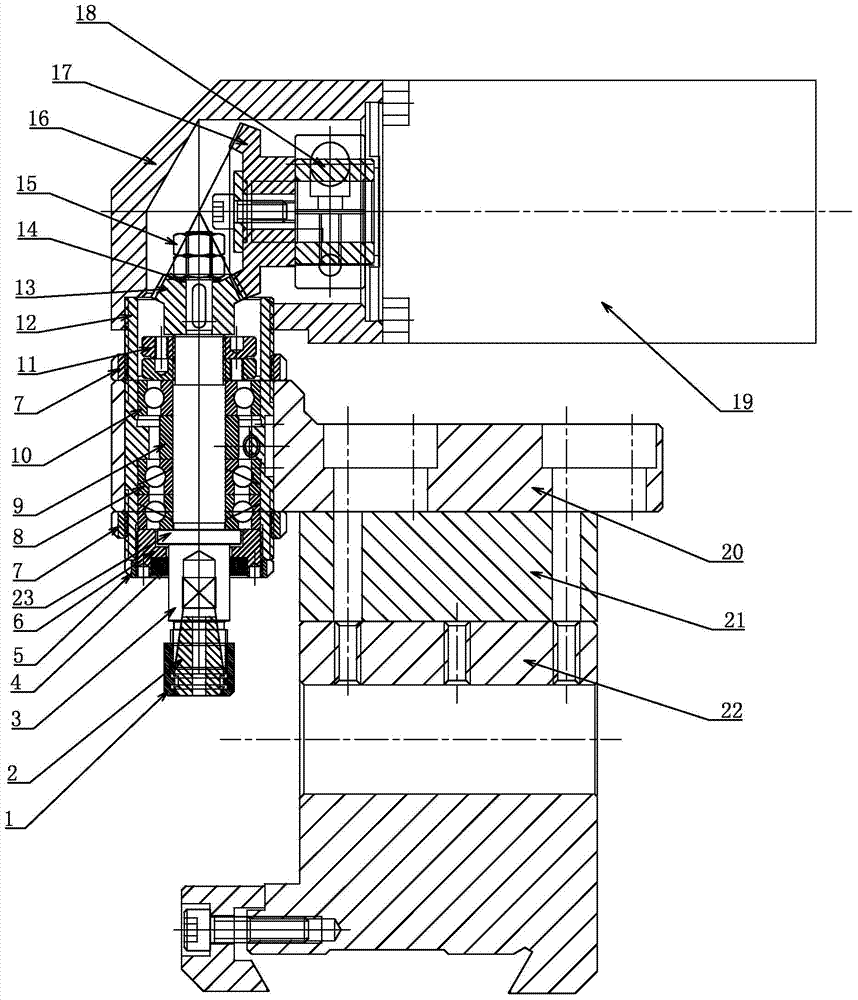

[0023] Example: such as figure 1 As shown, the present invention includes a servo motor 19, a gear box 16, first and second gears 13, 17 that cooperate with each other, a main shaft 3, a shaft housing 12 and a main shaft seat 20, and the main shaft seat 20 is fixed on the On the lathe tool rest 22, the main shaft 3 is installed on one end of the main shaft seat 20 through its shaft shell 12, and the collet 2 and the first nut 1 are installed on the working end of the main shaft 3 for adornment of the tool, and the other end is installed with the second nut 15 The first gear 13 and the second gear 17 matched with it are mounted on the output shaft end of the servo motor 19, and the gear box 16 is sleeved outside the two gears and connected with the motor housing and the main shaft housing 12 respectively. Wherein the first nut 1 and the collet 2 are purchased parts.

[0024] In this example, the main shaft 3 and its shaft housing 12 are connected through the first and second b...

Embodiment 2

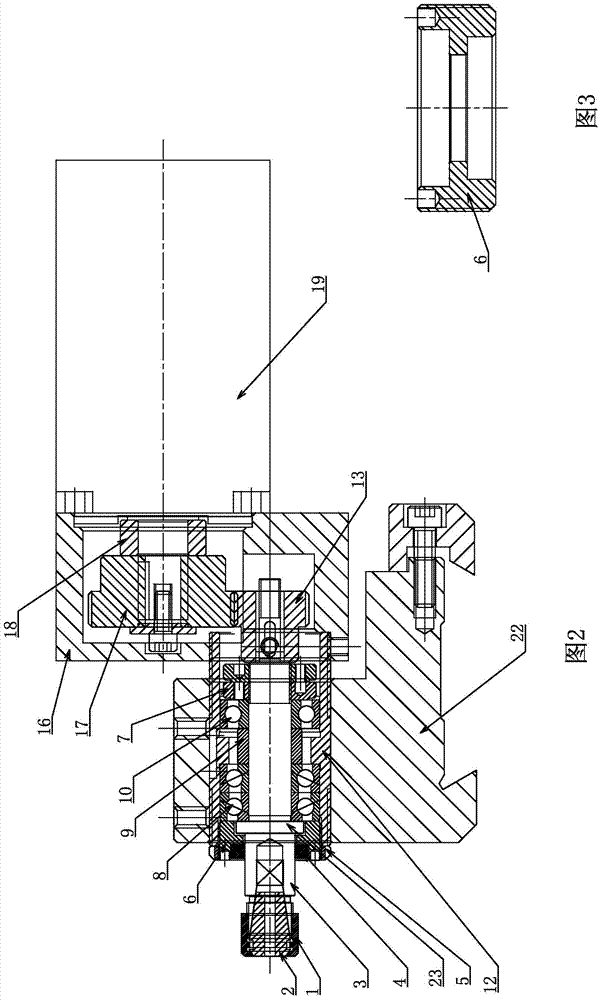

[0029] Embodiment 2: as figure 2 As shown, the difference between this example and Example 1 is that the first and second gears 13 and 17 in this example are both spur gears, the shafts of the two gears are parallel to each other, and the gear ratio is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com