Automatic brazing device of iron core of electromagnetic valve

A solenoid valve, iron core technology, applied in auxiliary devices, arc welding equipment, welding equipment and other directions, can solve the problems of difficult welding connection, low welding quality, low production efficiency, etc., to improve welding efficiency, stable welding quality, Good mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

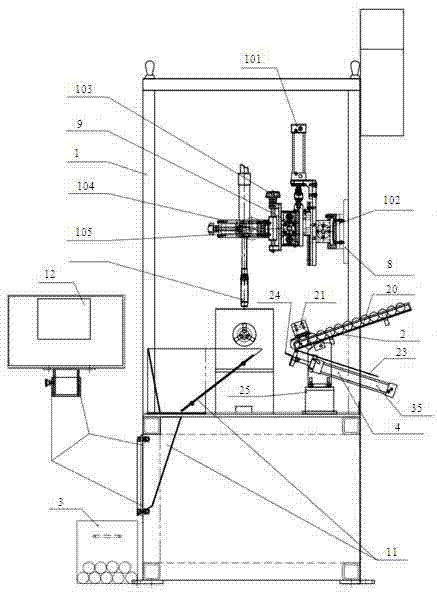

[0036] In the embodiment, take the processing of a certain workpiece as an example: the pre-order work of welding is to input the corresponding program in the control system to automatically adjust the state of the internal equipment;

[0037] (1) First adjust the welding torch adjustment mechanism 8, respectively use the welding torch X-direction adjustment 102, welding torch Y-direction adjustment 103 and welding torch Z-direction adjustment 104 to adjust the three-dimensional space position of the fixed welding torch, so that the welding torch reaches the corresponding position, and at the same time adjust the welding torch angle adjustment 105 position to ensure that the welding torch can accurately process the workpiece;

[0038] (2) Then adjust the workpiece fixing mechanism 27, the workpiece tightening mechanism is to move the unwelded workpiece into the welding position, select the corresponding rotary center head 29 according to the change of the length and diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com