Inclined rotary plate chute

A turntable and chute technology, applied in the field of mineral processing equipment, can solve the problems of large investment in equipment and auxiliary facilities, complex equipment structure, low processing capacity, etc., and achieve low installation and use costs, high mineral processing enrichment ratio, and large processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with example the present invention is further described.

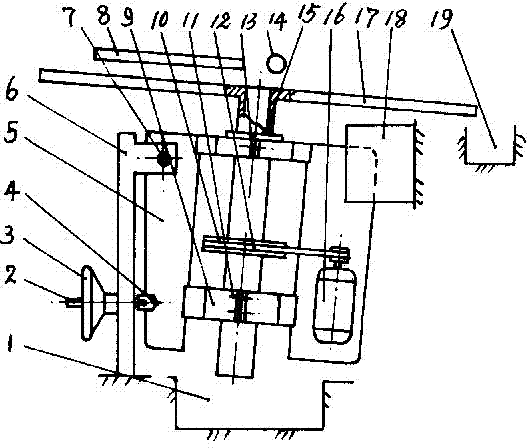

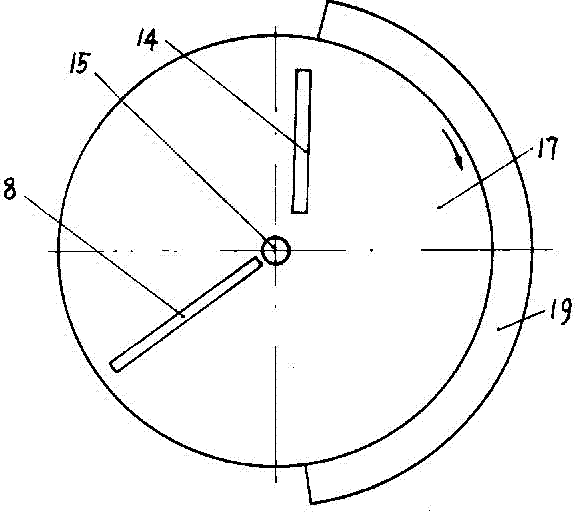

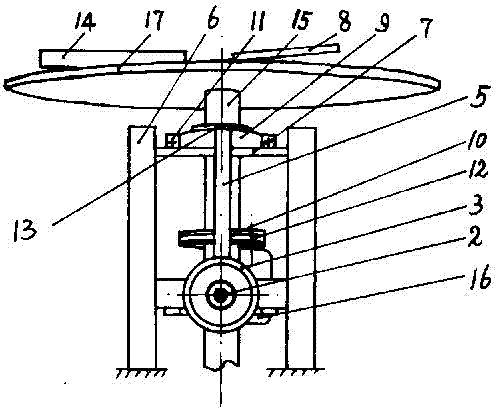

[0027] like Figure 1-3 As shown, the turntable 17 is made into a flat disk with a diameter of 4m with a 5mm thick steel plate, and the center pipe 15 is welded with the turntable after being blanked with an outer diameter of 20cm and a steel pipe with a wall thickness of 2-3mm. The centerline coincides with the centerline of the turntable. Disc seat 5 is made respectively with left and right two steel plates and is welded as a whole with the half welding of butt axle seat 9. The docking shaft seat consists of two semicircular sleeves. Because the rotation speed of the center tube is not high and the wear is not large, the center tube can be directly wrapped in the sleeve to rotate, and a limit ring 13 is set on the center tube to ensure that the center tube does not move axially, and the gap between the docking shaft seat and the center tube Add some lubricant to reduce wear. Of course,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com