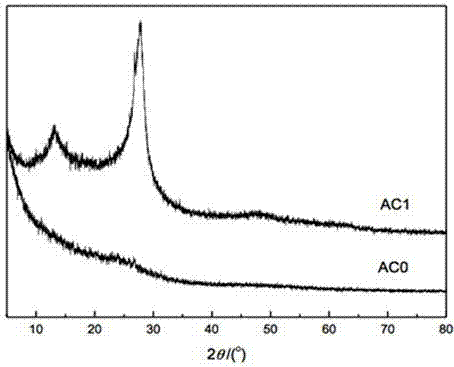

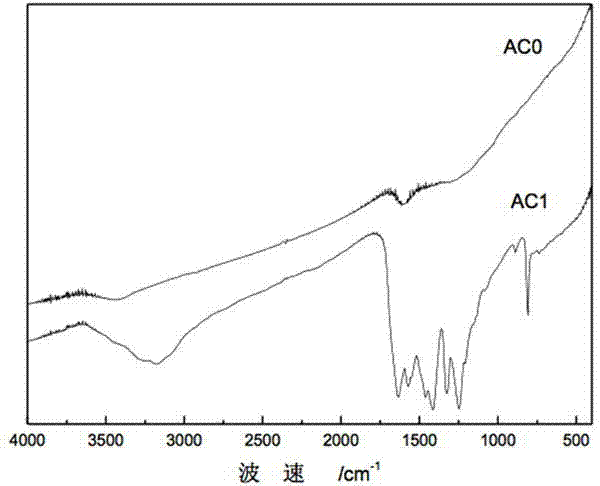

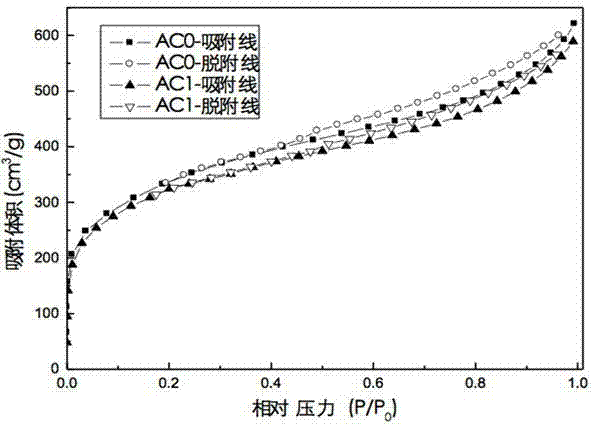

Preparation method of g-C3N4-suppurted active carbon with photocatalytic function

A technology of activated carbon and photocatalysis, applied in the field of activated carbon, which can solve the problems of complex process, harsh operating conditions and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 5g of activated carbon, 1g of trichloroazine (C 3 N 3 C1 3 ) and 0.5g of lithium nitride (Li 3 N) Put it in a high-pressure reactor, add 50 ml of benzene, feed nitrogen to fully drive away the air in the reactor system, apply a pressure of 30 MPa in the reactor, and then make the reactor in the reactor at a speed of 1°C / min The temperature was raised to 320°C and reacted at constant temperature and pressure for 4 hours, then naturally cooled to room temperature, benzene was filtered off, and the product was washed successively with 50 mL of 0.02 mol / L hydrochloric acid and 50 mL of acetone, and then repeatedly washed with distilled water until The filtrate was neutral, and the product was washed twice with 100 mL of absolute ethanol, and dried in a vacuum oven at 85 °C for 24 h to obtain photocatalytic functional activated carbon.

Embodiment 2

[0035] Get 8g of activated carbon, 3g of trichloroazine (C 3 N 3 C1 3 ) and 2g of lithium nitride (Li 3N) Put it in a high-pressure reactor, add 100 ml of benzene, feed nitrogen to fully drive away the air in the reactor system, apply a pressure of 35MPa in the reactor, and then make the reactor in the reactor at a speed of 0.1°C / min The temperature was raised to 300°C and reacted at constant temperature and pressure for 6 hours, then naturally cooled to room temperature, benzene was filtered off, and the product was washed with 50 mL of 0.05 mol / L hydrochloric acid and 50 mL of acetone in sequence, and then washed repeatedly with distilled water until The filtrate was neutral, and the product was washed twice with 100 mL of absolute ethanol, and dried in a vacuum oven at 85 °C for 24 h to obtain photocatalytic functional activated carbon.

Embodiment 3

[0037] Get 6g of activated carbon, 2g of trichloroazine (C 3 N 3 C1 3 ) and 1.5g of lithium nitride (Li 3 N) Put it in a high-pressure reactor, add 90 ml of benzene, feed nitrogen to fully drive away the air in the reactor system, apply a pressure of 38 MPa in the reactor, and then make the reactor in the reactor at a speed of 0.5 °C / min The temperature was raised to 310°C and reacted at constant temperature and pressure for 5 hours, then naturally cooled to room temperature, benzene was filtered off, and the product was washed with 50 mL of 0.01mol / L nitric acid and 50 mL of acetone in sequence, and then washed repeatedly with distilled water until The filtrate was neutral, and the product was washed twice with 100 mL of absolute ethanol, and dried in a vacuum oven at 85 °C for 24 h to obtain photocatalytic functional activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com