Opposite-roller type pitting machine

A roller type, nuclear motor technology, applied in fruit de-pitting device, food science, application and other directions, can solve the problems of easily broken fruit core, unsightly, rough appearance of fruit core, etc., achieves small space occupation, compact and reasonable structure, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

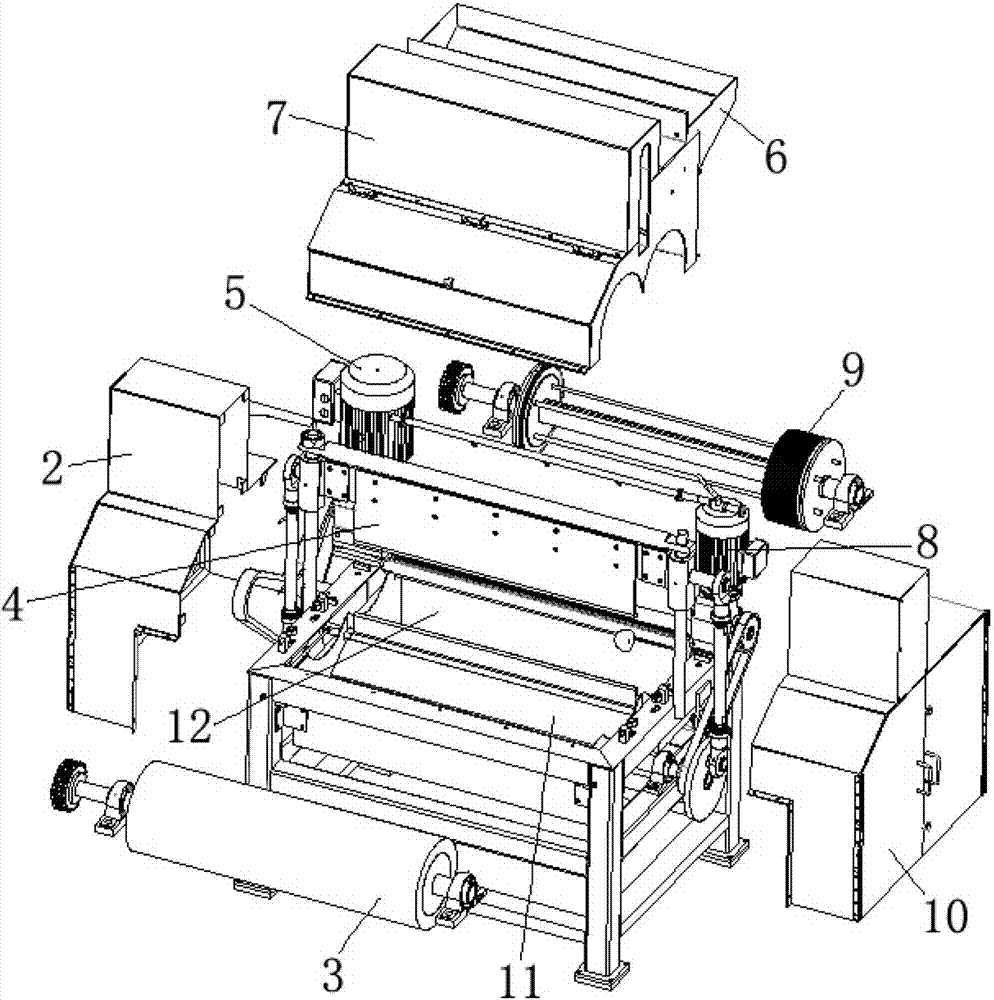

[0018] like figure 1 , figure 2 As shown, a pair of roller-type nuclear removing machine includes a frame 1 and a rubber roller 3 installed on the frame 1, a toothed roller 9, a nuclear pressing mechanism 4, a housing 7, a main driving motor 5 and a nuclear pressing power Machine 8, the rotating shaft of the rubber roller 3 and the rotating shaft of the toothed roller 9 are parallel to each other, a material processing gap is formed between the rubber roller 3 and the toothed roller 9, and the main driving motor 5 drives the rubber roller 3 and the toothed roller 9 to face each other through the transmission mechanism Rotate, there is a pressing mechanism 4 directly above the material processing gap, the pressing motor 8 drives the pressing mechanism 4 to move up and down through the transmission mechanism, and the shell 7 is arranged on the outside of the rubber r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com