Storage battery recovery and separation system

A separation system and storage battery technology, applied in battery recycling, wet separation, solid separation, etc., can solve the problems of single separation of recycling equipment, poor separation effect, waste of water resources, etc., to improve separation effect, facilitate recycling and two The effect of secondary utilization and reduction of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

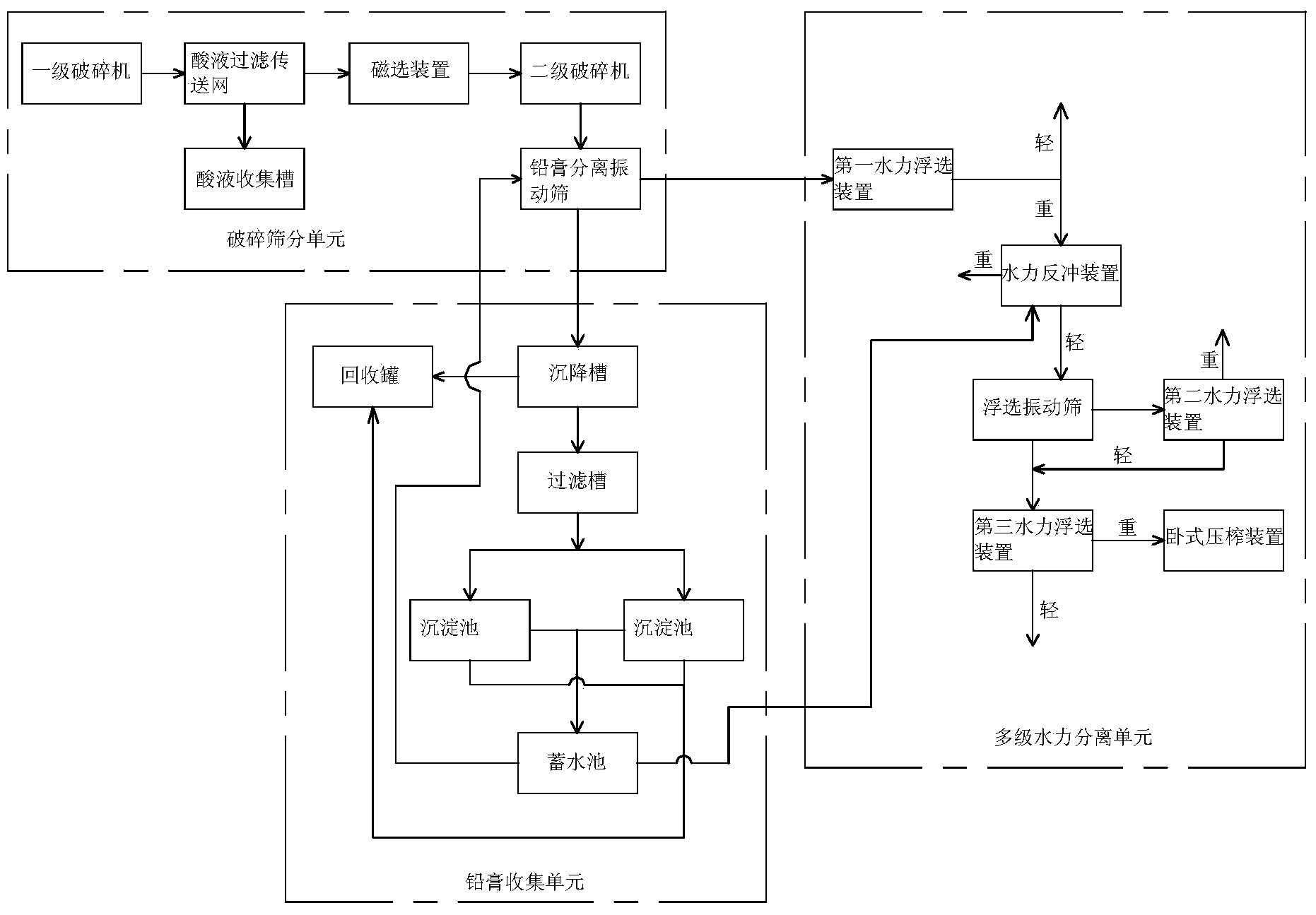

[0054] Such as figure 1 As shown, the storage battery recovery and separation system in this embodiment includes: a crushing and screening unit, which crushes and screens the battery to be recovered; a lead paste recovery unit, which collects the undersize separated by the crushing and screening unit; The separation unit separates the oversize material separated by the crushing and screening unit.

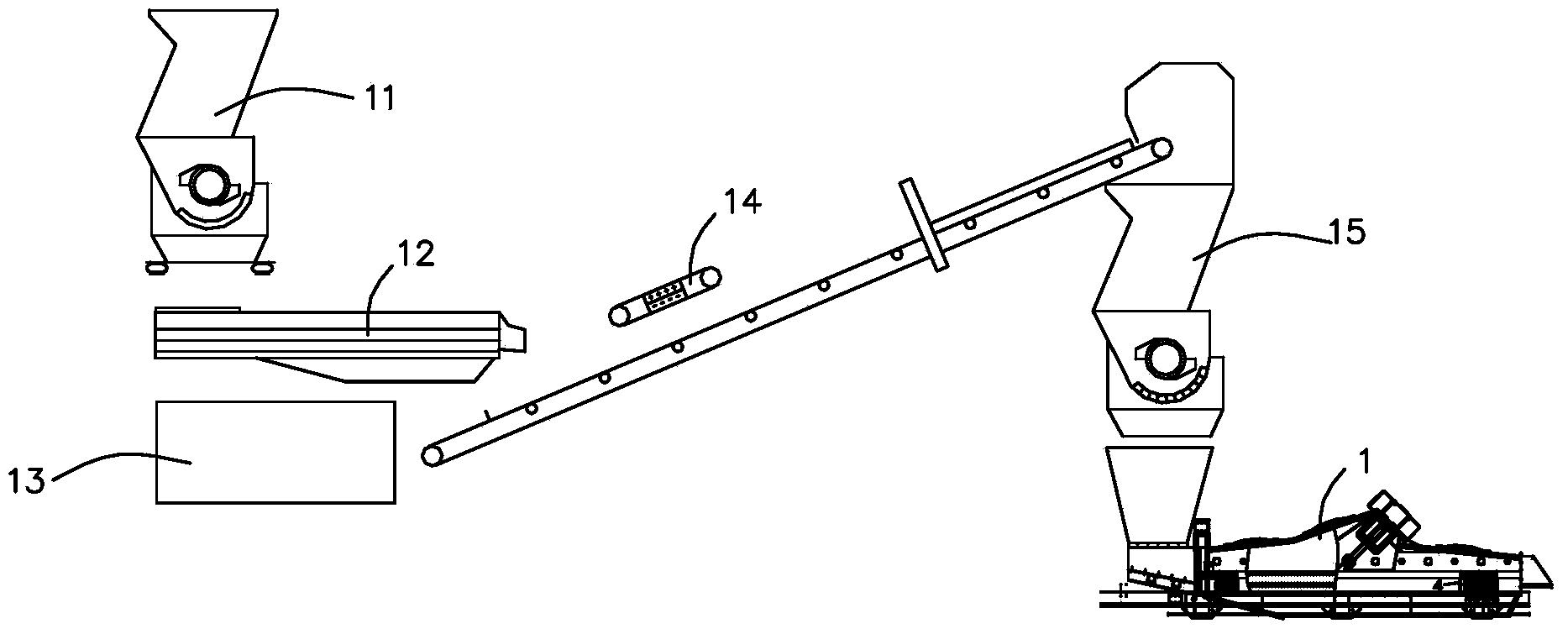

[0055] Such as figure 2 As shown, the crushing and screening unit includes: a first-stage crusher 11 for crushing the battery for the first time; an acid filter conveying net 12 connected to the outlet of the primary crusher; located below the acid filter conveying net 12 for collecting The acid liquid collection tank 13 of acid liquid; The magnetic separation device 14 that conveyer belt is provided with below, and conveyer belt undertakes the mixture above described acid liquid filtration conveying net 12; Feed inlet is arranged on the secondary breaker 15 below conveyer belt, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com