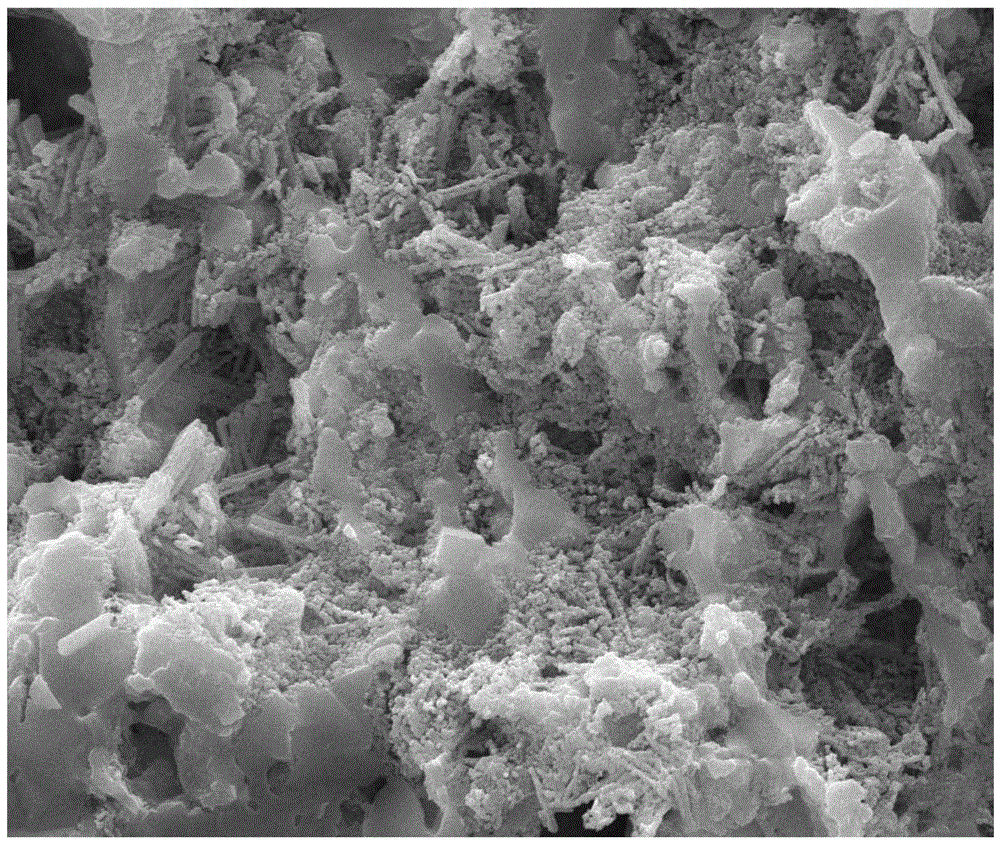

Method for preparing acicular metal Ni on inner surface of porous substrate at high temperature

A porous substrate and inner surface technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy sintering and poor working stability of Ni-based anodes, and achieve long-term high-temperature working stability, stability improvement, and preparation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1: The method for preparing acicular Ni at a high temperature on the inner surface of a porous substrate provided by this embodiment is completed according to the following steps:

[0016] 1. Preparation of nickel metal salt precursor solution: Dissolve the solid nickel metal salt in the solvent, and stir for 5 min to 30 min at a stirring rate of 100r / min to 800r / min to obtain a nickel metal salt solution, and then pour the nickel metal salt solution into the nickel metal salt solution Adding complexing agent in 100r / min~800r / min stirring rate, stirring 20min~200min, obtain nickel metal salt precursor solution; Wherein the ratio of the substance amount of nickel metal salt and complexing agent is 1:( 0.5~5), the molar concentration of nickel metal salt precursor solution is 2mol / L~3mol / L;

[0017] 2. Preparation of the porous substrate skeleton: take the porous substrate material as the ball milling substrate, and ball mill it for 24h to 48h under th...

specific Embodiment approach 2

[0023] Specific embodiment two: The difference between this embodiment and specific embodiment one is that the solvent described in step one is one or more of deionized water, acetic acid, ethanol, propanol or ethylene glycol in any proportion mix. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the nickel metal salt described in step 1 is nickel nitrate hexahydrate, nickel chloride or nickel acetate. Others are the same as one of Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com