A packer for volume fracturing of horizontal wells

A volume fracturing and packer technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc. The effect of unsealing and reducing the risk of sand trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

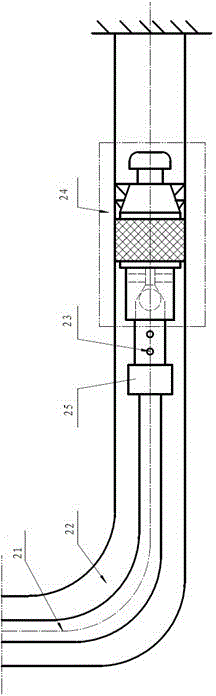

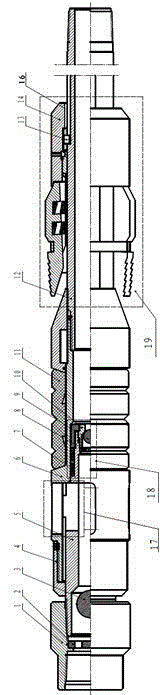

[0021] The present invention provides a packer for volume fracturing of horizontal wells, with reference to figure 2 As shown, the packer 24 is a cylindrical compression packer, which includes an upper check valve, a reverse circulation channel 17, a rubber cylinder 11 and a mechanical anchoring mechanism 19. The upper check valve includes an upper joint 1, a mandrel 5 and steel ball 3, the upper joint 1 is threaded to the mandrel 5 from the outside, the inner diameter of the lower part of the mandrel 5 is smaller than the upper inner diameter, the steel ball 3 is placed in the mandrel 5, and the diameter of the steel ball 3 is larger than the lower part of the mandrel 5. The inner diameter is smaller than the inner diameter of the upper part of the mandrel 5, so that the steel ball 3 is stuck in the mandrel 5. The upper check valve mechanism can prevent the upper liquid flow of the upper check valve mechanism from flowing downward to ensure the normal perforation operation; at...

Embodiment 2

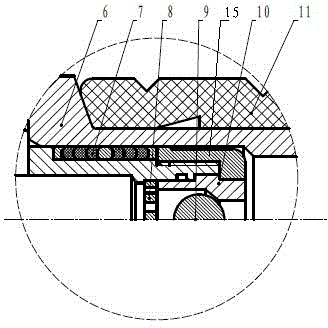

[0027] As an improvement to the packer described in Example 1, such as figure 1 , image 3 As shown, it also includes a balancing mechanism 18, which is located at the tail end of the mandrel 5 and fits and seals with the outer sleeve 6, including a combined seal group 7 and a lower check valve. The combined seal group 7 is embedded in the mandrel 5 and the outer sleeve. Between 6, can be sealed. The lower check valve is located inside the mandrel 5, including the steel ball 9 and the ball seat 10. The ball seat 10 is embedded inside the mandrel 5, the inner diameter of the ball seat 10 shrinks backward in the middle, and the diameter of the steel ball 9 is smaller than the front of the ball seat 10. The inner diameter of the ball seat 10 is larger than the inner diameter of the rear portion of the ball seat 10, so that the steel ball 9 is stuck in the ball seat 10. The lower check valve mechanism can prevent the liquid in the string from flowing to the lower annulus of the pac...

Embodiment 3

[0031] As an improvement of the embodiment 2, the upper check valve mechanism has a baffle 2 at the end of the core shaft 5 inside the upper joint 1, and the lower check valve mechanism has a baffle at the end of the ball seat 10 inside the core shaft 5. No. 8, the first baffle 2 and the second baffle 8 are provided with through holes along the axial direction. The through hole ensures that the liquid flow can pass through, and the steel ball is blocked by the baffle, and will not flow into the pipe string along with the liquid flow because it is pushed away by the liquid flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com